Cracking self-prompting type shoemaking process

A process and shoe upper technology, which is applied in the field of cracking self-reminder shoemaking process, can solve the problems of limited strength, enlarged cracks, cracking, etc., and achieve the effect of prolonging the service life and improving the ability to resist non-vertical deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

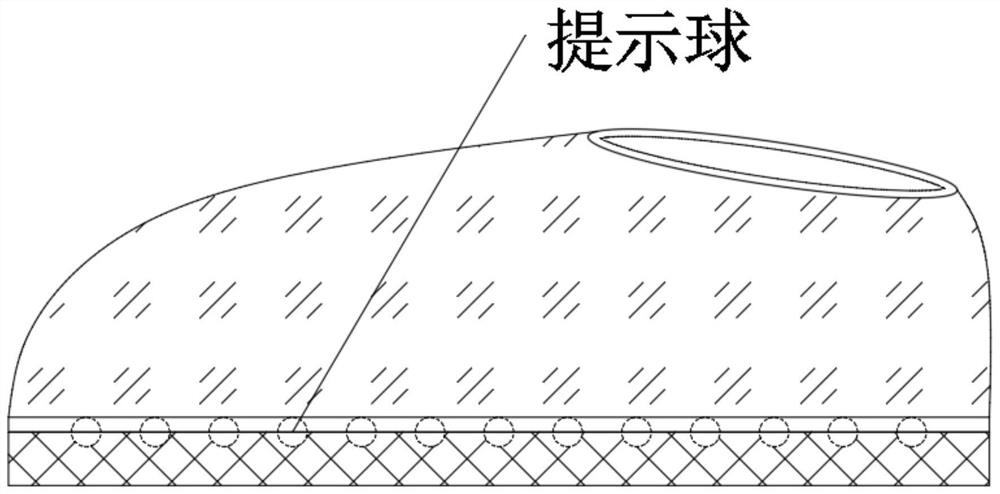

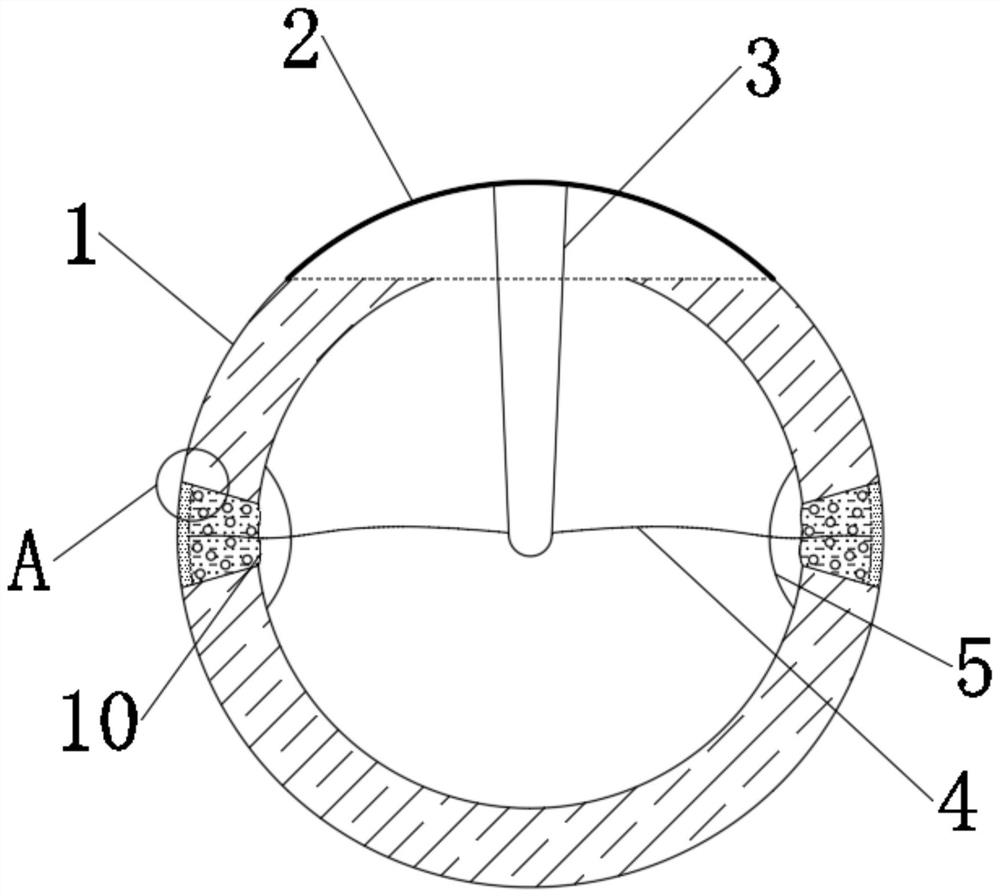

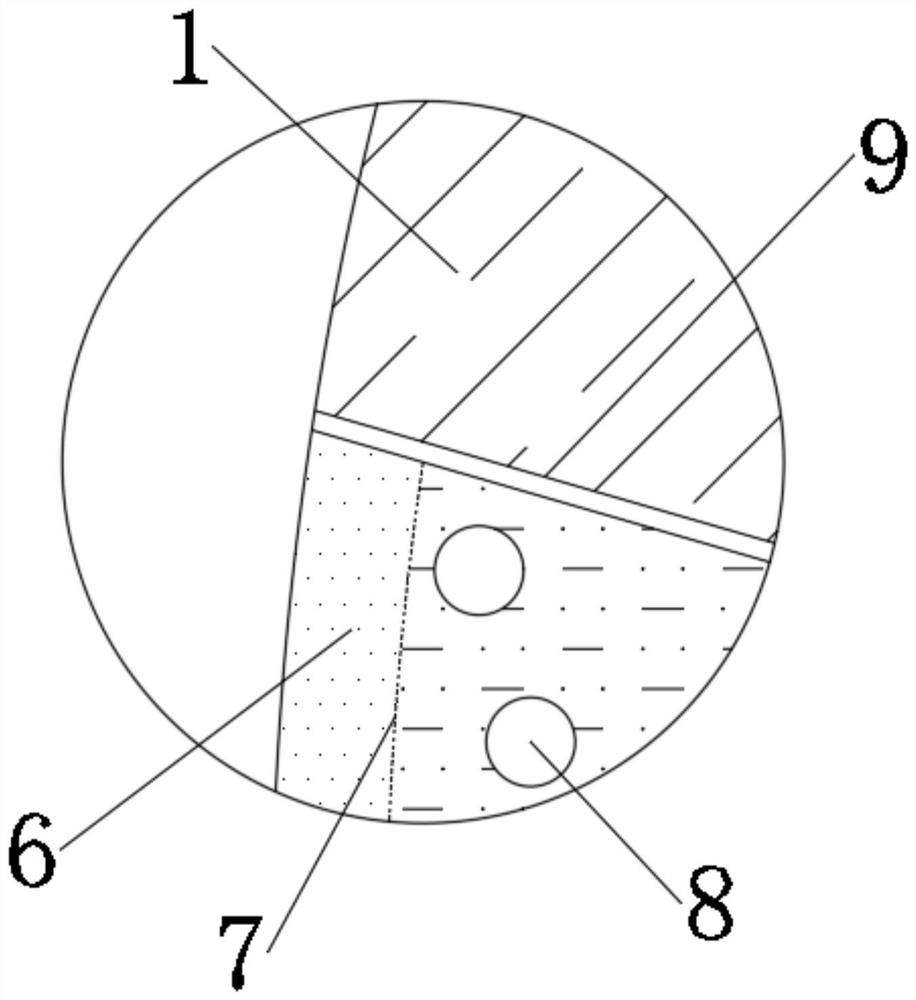

[0047] see figure 1 , a cracking self-reminder type shoe-making process, comprising the following steps:

[0048] S1. Use a grinding wheel to sand the surface of the sole to be bonded to make the surface rough, and then remove the sanding dust;

[0049] S2. Brush the adhesive onto the joint between the sole and the upper, and then take multiple prompt balls and bury them evenly in the adhesive on the sole in an oxygen-free environment, and wait for the adhesive to dry naturally;

[0050] S3. Apply pressure to the sole through the upper, and heat until the adhesive becomes sticky during the pressure application process, and continue to apply pressure until the upper and the sole are bonded;

[0051] S4. After the pressing is completed, observe whether the prompt ball has a crack prompt. If there is a crack prompt, separate the upper and sole to replace the prompt ball and then bond the second time. If there is no crack prompt, the bonding is qualified;

[0052] S5. After pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com