Automatic lubricating oil supplementing mechanism for guide rail of numerical control machining center

A machining center and automatic replenishment technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient inspection and use, and labor-intensive cleaning of impurities, so as to facilitate daily use, reduce labor intensity, and ensure The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

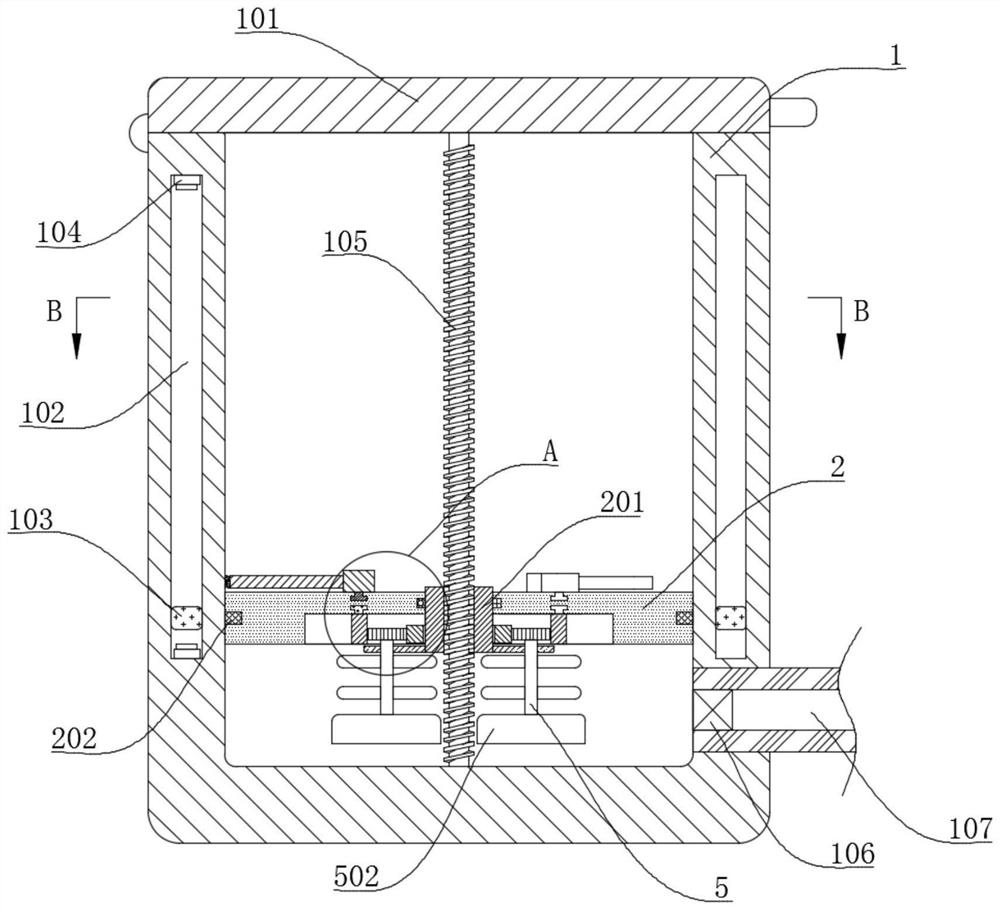

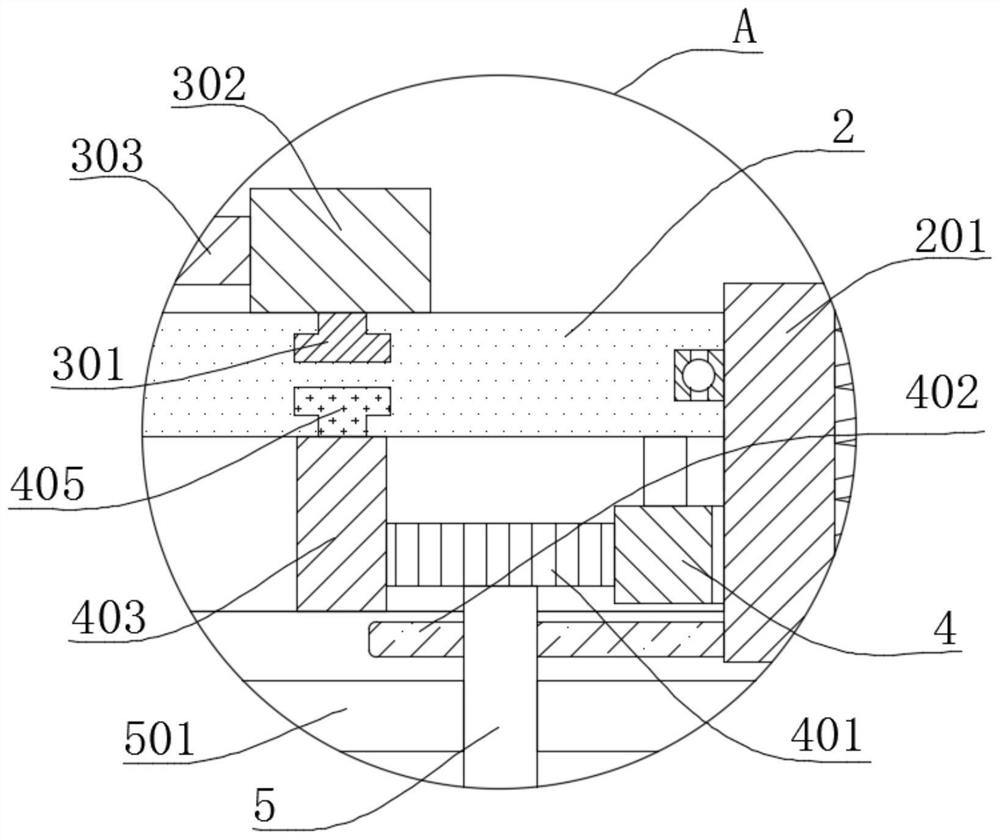

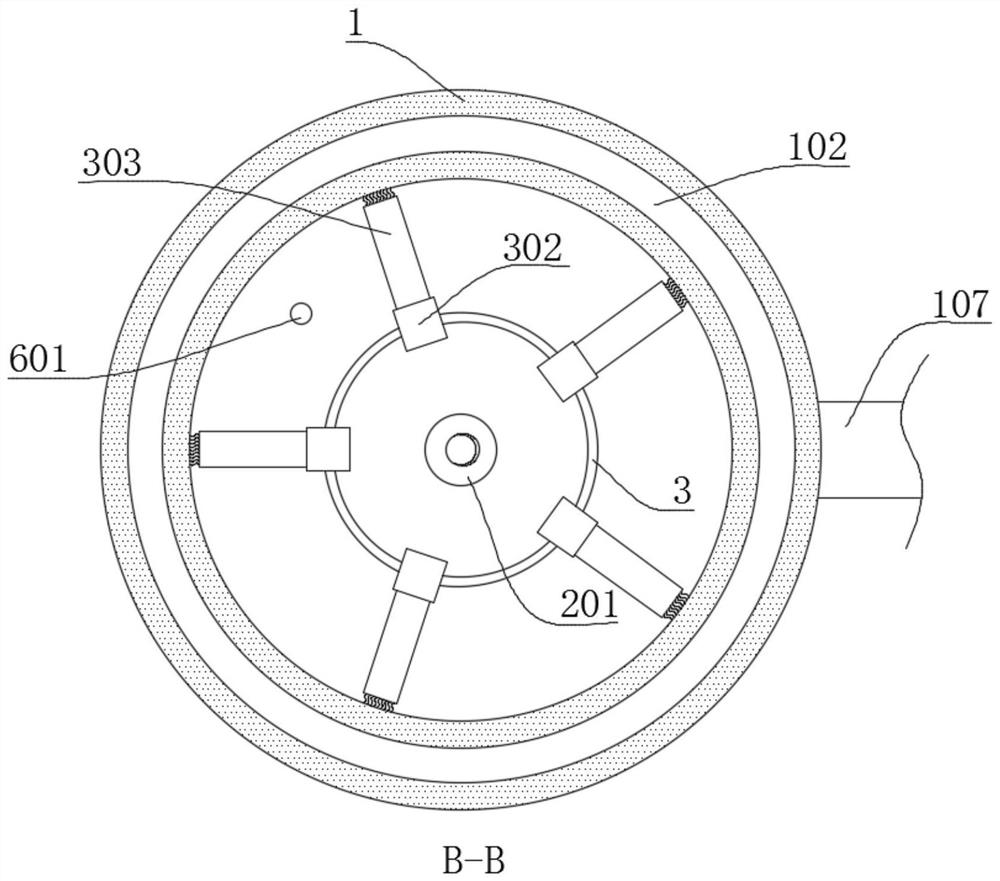

[0026] refer to Figure 1-3 , an automatic lubricating oil replenishment mechanism for guide rails of a numerically controlled machining center, comprising a fuel tank 1, a tank cover 101, a control cavity 102, an annular permanent magnet 103, a control button 104, a screw 105, a solenoid valve 106, an oil replenishment pipe 107, a control device, and a fuel tank 1 The cross-section of the tank is in a concave shape with the opening facing upwards. The tank cover 101 is connected to the fuel tank 1 through hinge rotation. The control cavity 102 is opened in the side wall of the fuel tank 1. The control cavity 102 is an annular cavity, and the annular permanent magnet 103 is slidingly sleeved in the control cavity 102. Inside, there are two control buttons 104, and the two control buttons 104 are respectively glued to the inner top wall and the inner top wall of the control chamber 102, the oil supply pipe 107 is fixedly connected with the fuel tank 1 and extends to the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com