Large 3D printer rack machining tool

A 3D printer and rack technology, used in additive processing, metal processing equipment, processing platforms/substrates, etc., can solve the problem that tooling components cannot be made into large racks, saving production time, strong practicability, design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

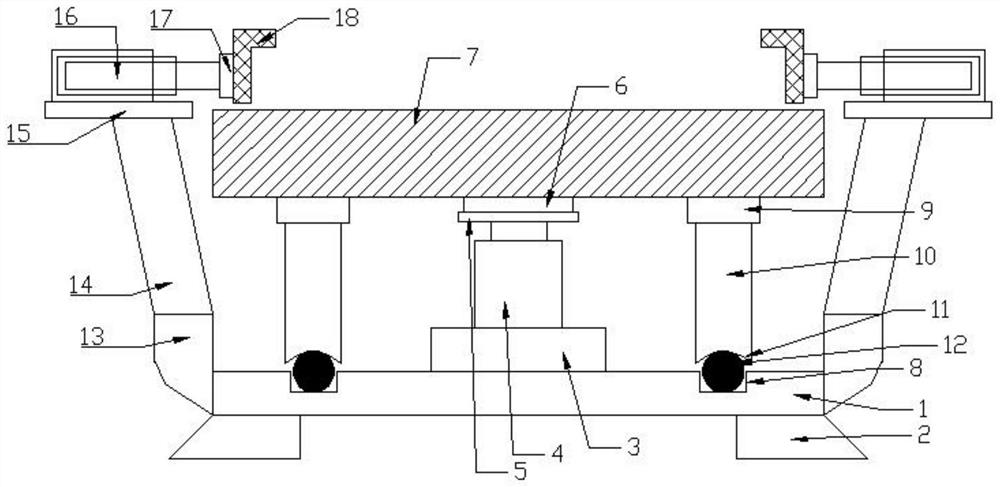

[0014] Such as figure 1 The shown large-scale 3D printer frame processing tooling includes a base plate 1, several supporting legs 2 arranged on one side of the base plate 1, and a motor mounting seat 3 arranged on the other side of the base plate 1, and a motor mounting seat 3 arranged on the base plate 1. The motor 4 on the top, and the connecting plate 5 arranged at one end of the motor 4, and the supporting block 6 arranged on one side of the connecting plate 5, and the working table 7 arranged on one side of the supporting block 6, and arranged on the other side of the base plate 1 and located at the motor The circular limit groove 8 of the mounting seat 3 outer layer, and several connection blocks 9 arranged on one side of the workbench 7, and the vertical support rods 10 respectively arranged on one side of the connection block 9, and respectively arranged on the vertical support rods 10 A semicircular groove 11 on one end surface, and several balls 12 arranged in the c...

Embodiment 2

[0016] Such as figure 1 The shown large-scale 3D printer frame processing tooling includes a base plate 1, several supporting legs 2 arranged on one side of the base plate 1, and a motor mounting seat 3 arranged on the other side of the base plate 1, and a motor mounting seat 3 arranged on the base plate 1. The motor 4 on the top, and the connecting plate 5 arranged at one end of the motor 4, and the supporting block 6 arranged on one side of the connecting plate 5, and the working table 7 arranged on one side of the supporting block 6, and arranged on the other side of the base plate 1 and located at the motor The circular limit groove 8 of the mounting seat 3 outer layer, and several connection blocks 9 arranged on one side of the workbench 7, and the vertical support rods 10 respectively arranged on one side of the connection block 9, and respectively arranged on the vertical support rods 10 The semicircular groove 11 on one end face, and the several balls 12 that are arran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap