Rapid cleaning and maintaining mechanism for blanket cylinder of offset press

A technology of blanket cylinders and offset printing presses, applied in general parts of printing machinery, printing machines, printing and other directions, can solve the problems of expensive automatic cleaning devices, difficult to achieve cleaning effect, accelerated aging of blankets, etc., so as to reduce wiping damage , compact structure, the effect of promoting liquid evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail through the examples below, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

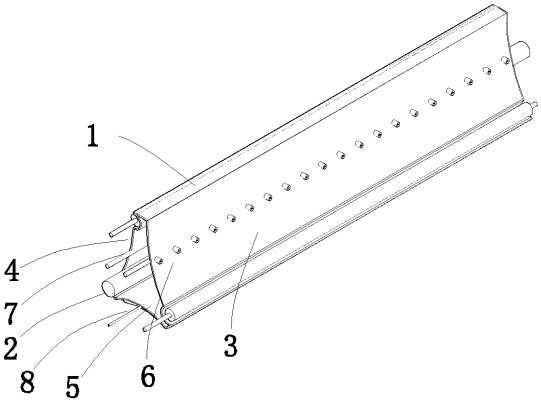

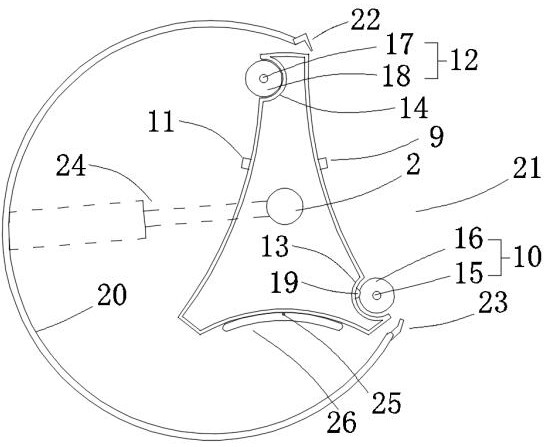

[0035] Such as Figure 1-2 As shown, a quick cleaning and maintenance mechanism for the rubber cylinder of an offset printing machine is used to be installed on the offset printing machine to clean and maintain the rubber cylinder; There are three arc-shaped and concave mounting plates arranged around the rotating shaft on the top, which are respectively: a water washing device mounting plate 3, a detergent washing device mounting plate 4, and a reducing agent application device mounting plate 5. The water washing device mounting plate is arranged with A washing device 6, a cleaning agent washing device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com