An installation method of windproof bias rigid insulation cable for high voltage transmission line

A technology of high-voltage transmission lines and installation methods, which is applied in the direction of overhead lines/cable equipment, mechanical vibration attenuation devices, etc., can solve the problems of high cost of reconstruction and installation, inconvenience of transportation, and increase of poles and towers, so as to improve the level of safe operation and avoid wind deflection Tripping, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention is applied to high-voltage transmission lines of all voltage levels prone to wind deviation, especially to 500kV high-voltage transmission lines.

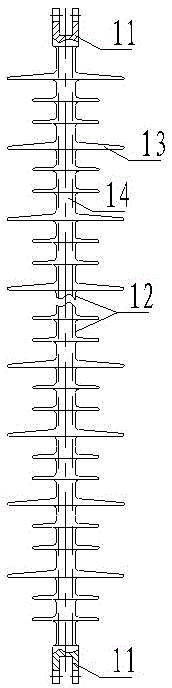

[0021] Such as figure 1 As shown, the cable 1 of the present invention includes a rod body 12, the upper and lower ends of the rod body 12 are respectively connected with high-voltage end fittings 11, the rod body 12 includes an umbrella skirt 13 and a rod core 14, and the surface layer of the rod body 12 is an insulating umbrella skirt 13 , The umbrella skirt 13 is a silicone rubber composite material. The rod core 14 is located in the shed 13, and the rod core 14 is an epoxy resin glass drawing rod. The high-voltage end fittings 11 are used to connect with the tower body. When connecting and installing, you only need to punch holes on the tower body and install the commonly used matching connecting fittings, which is easy to operate.

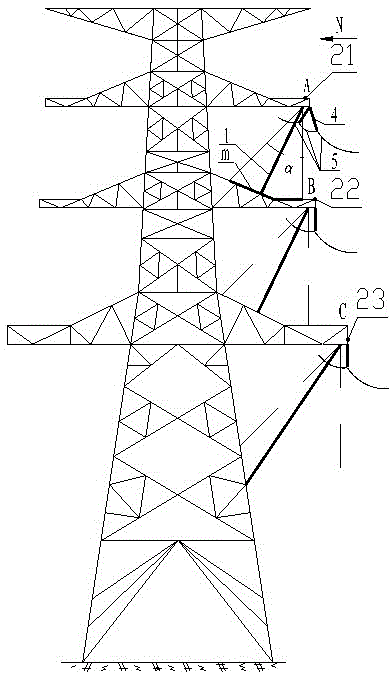

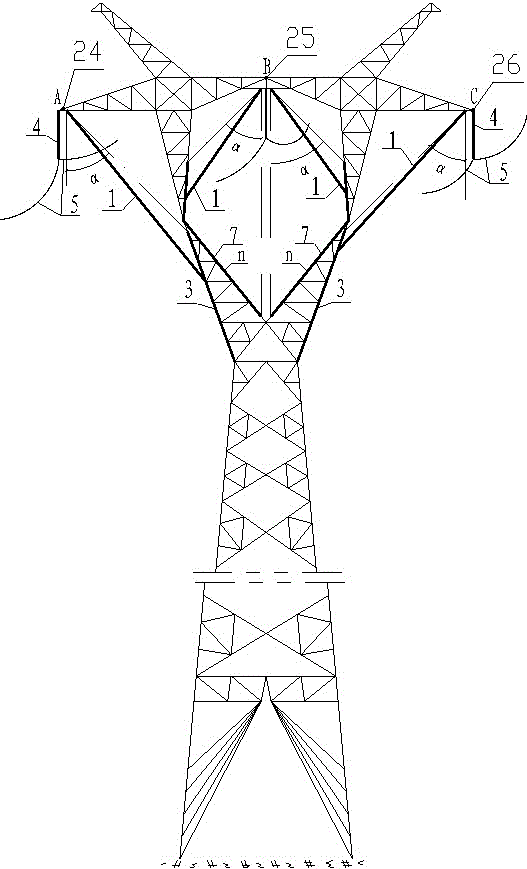

[0022] Such as figure 2 As shown, the single-circuit line of a 500kV d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com