Novel automatic laser printer

A laser printer, a new type of technology, used in typewriters, printing devices, printing and other directions, can solve the problems of unprintable object positioning, poor adjustment flexibility, troublesome operation and use, etc., to achieve positioning and clamping effect, reduce scrap rate, and achieve high Adjust the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

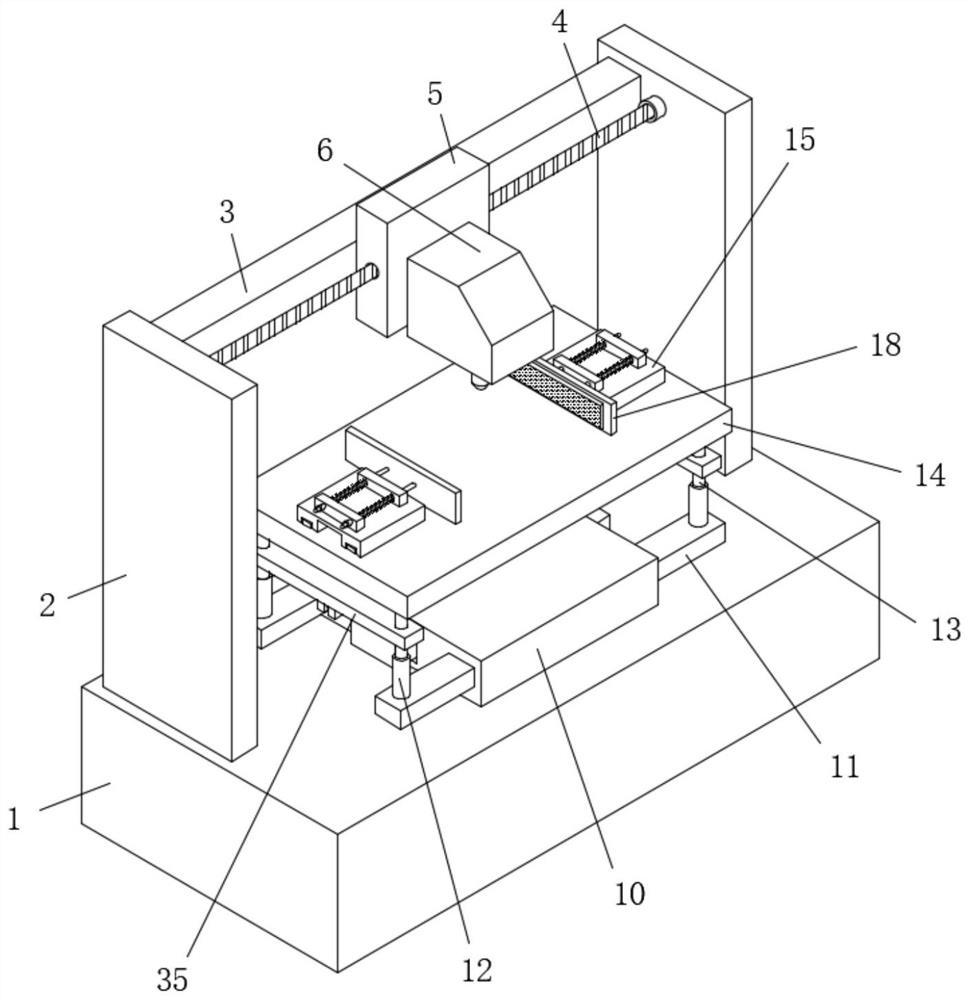

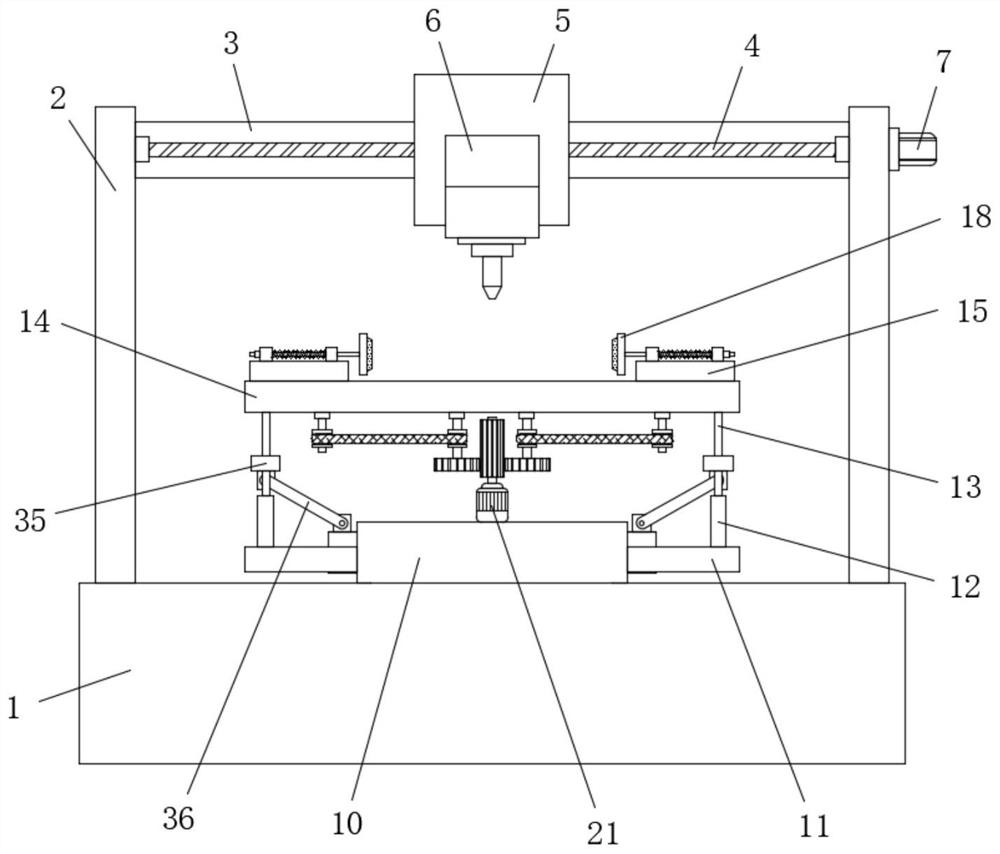

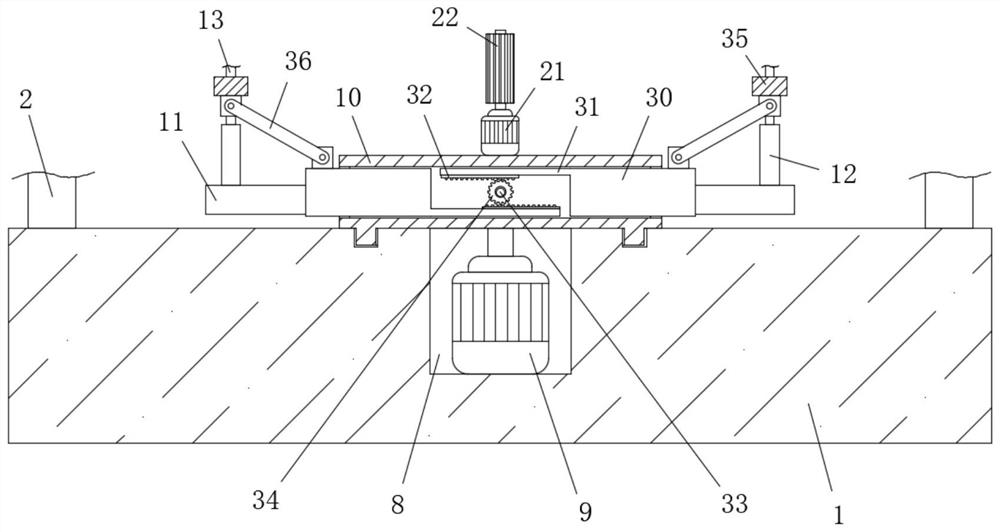

[0035] 3. Reference Figure 1-8 , a new type of automatic laser printer, comprising a base 1, two vertical boards 2 are symmetrically fixedly connected to both sides of the top of the base 1, and the two vertical boards 2 are parallel to each other, between the two vertical boards 2 Fixedly connected with a horizontal plate 3, the horizontal plate 3 and the vertical plate 2 are perpendicular to each other, the side of the horizontal plate 3 is slidably connected with a mounting nut plate 5, and the mounting nut plate 5 is fixedly connected with a laser printer 6, and the laser printer 6 Located on both sides of the mounting nut plate 5 respectively with the horizontal (3), a printing table 14 is set below the laser printer 6;

[0036]The printer also includes a first servo motor 9, a first drive assembly and a second drive assembly, the first servo motor 9 is used to rotate the print table 14, and the first drive assembly is used to clamp the print table 14 to print The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com