Rotating arm mechanism of can casting production line

A technology of production line and swivel seat, which is applied in the field of the canister arm mechanism of the tank feeding production line, can solve the problems of difficult control of the feeding process and easy sticking of viscous materials in the tank body, and achieve the effect of high working efficiency, stable and reliable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

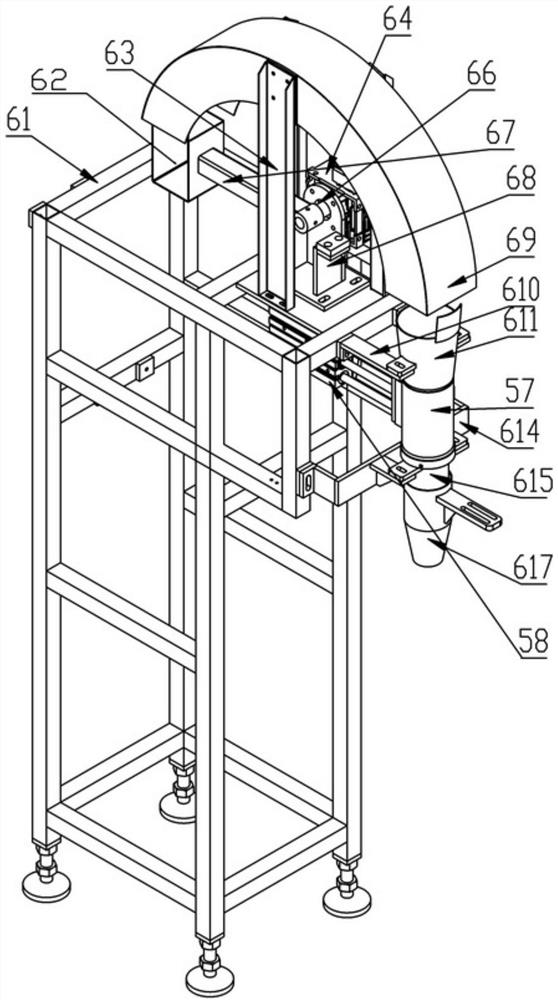

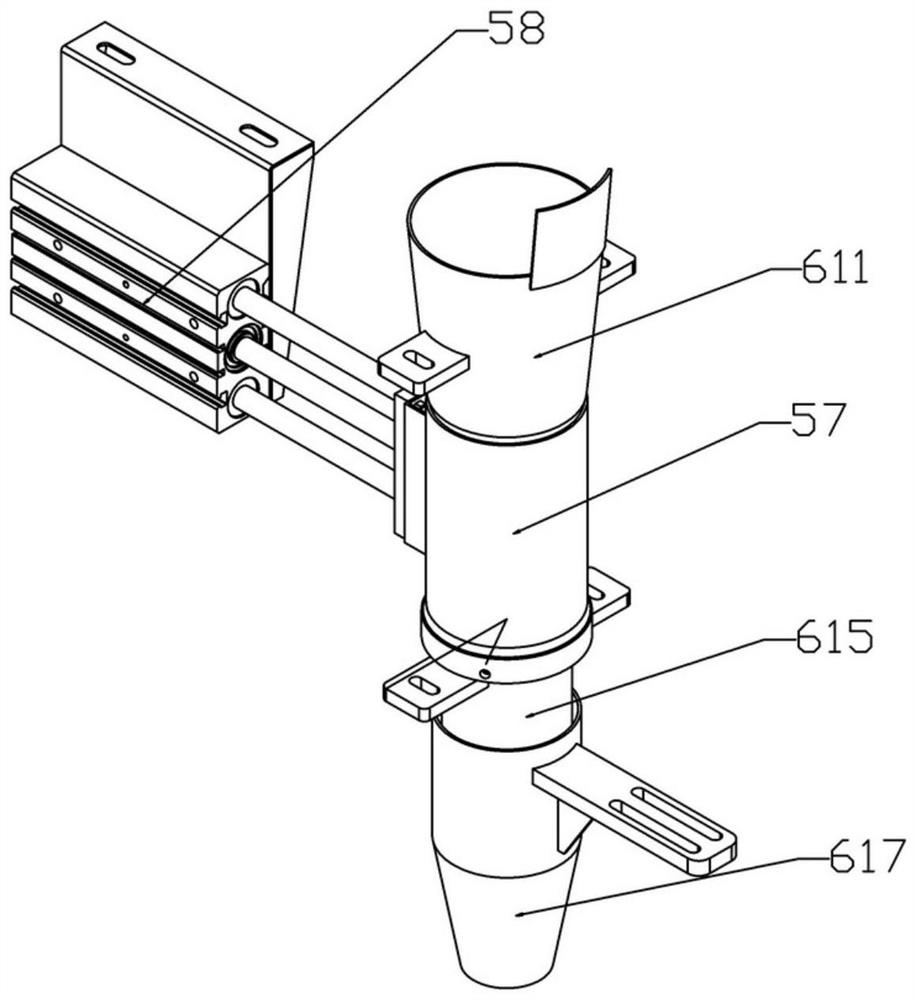

[0028] see Figure 1-2 , a rotary arm mechanism of a tank casting production line, which has:

[0029] base;

[0030] Shield mounting bracket, installed on the base;

[0031] The shield is installed on the shield mounting bracket, the shield is arc-shaped, and the bottoms of the two ends of the shield are open structures;

[0032] The swing arm is rotated and installed on the base;

[0033] The swivel seat is installed on the first end of the swivel arm, and the swivel seat can support; the swivel arm can drive the swivel seat to rotate in the shield;

[0034] The rotary drive mechanism can drive the rotary arm to rotate;

[0035] The tank full of materials can enter the rotating seat and move from the first end of the shield to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap