Automatic pulp feeding process

An automatic feeding and pulp technology, which is applied in recycling technology, sustainable manufacturing/processing, final product manufacturing, etc., can solve problems such as pulp accumulation, reduce labor intensity, reduce mechanical transmission structure, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment is an automatic feeding process for pulp.

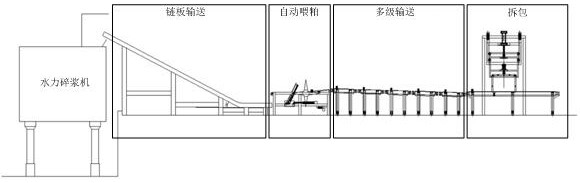

[0056] use as figure 1 As shown in the process flow, the pulp is sent to the hydropulper after unpacking, multi-stage conveying, automatic meal feeding and chain plate conveyance, and is mixed with lye in the hydropulper. The specific process flow can be The overview is as follows:

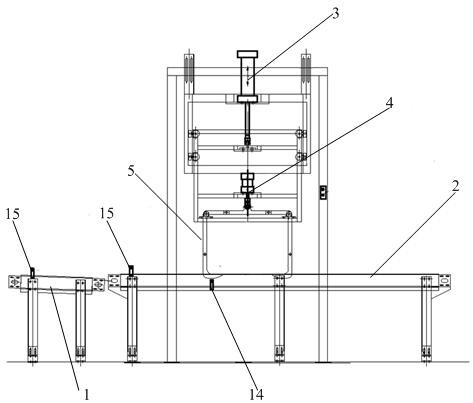

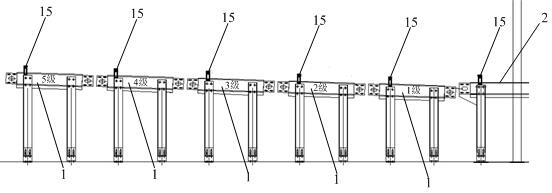

[0057] The packaged pulp is placed on the unpacking conveyor platform 2 by a forklift, and the conveying motor is started, and the pulp is sent to the bottom of the bale lifter by the nailed conveyor belt of the unpacking conveyor platform 2. The bale lifter is equipped with a lifting cylinder 3 and a clamping cylinder 4. The clamping cylinder 4 controls the manipulator 5 to clamp the pulp, and the lifting cylinder 3 is used to lift the pulp. For example, in a specific embodiment, the unpacking process flow is: adopt figure 2 The structure shown adopts the unpacking conveying platform 2 and the bale lifter arranged above the un...

Embodiment 2

[0065] Using the automatic pulp feeding process described in Example 1, the concentration of the porridge in the hydropulper was sampled and tested, and compared with the existing semi-automatic pulp feeding process, as shown in Table 1 below.

[0066] Table 1 Concentration comparison data of porridge

[0067]

[0068] In the raw liquid preparation process of viscose fiber production, the stability of the pressing and aging process can be guaranteed through the stability of the front-end pulp impregnation process.

[0069] In this embodiment, the function of pressing is to squeeze out excess lye, remove hemicellulose and impurities, and ensure the stability of a-cellulose content. In a specific embodiment, under the premise of the same pressing process, after adopting the pulp automatic feeding process described in Example 1, the qualified rate of the α-cellulose content in the pressing process is raised from 80% before it is not adopted to 95%.

[0070] The effect of agi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com