A kind of indirect brazing method of aluminum nitride ceramic copper clad laminate

A technology of aluminum nitride ceramics and brazing method, which is applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve the problems of residual stress accumulation, large connection area of ceramic copper clad laminates, etc., to reduce the coefficient of thermal expansion and reduce the level of residual stress Effect

Active Publication Date: 2022-05-31

CHANGCHUN UNIV OF TECH

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

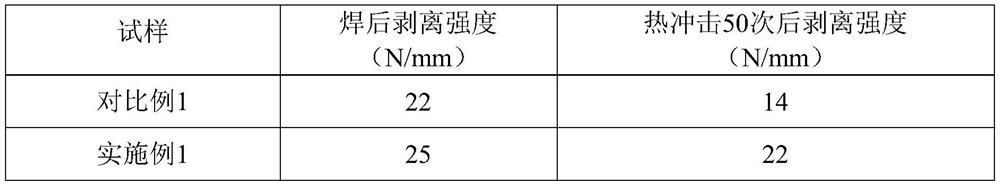

[0004] However, due to aluminum nitride ceramics (4.7×10 -6 ℃ -1 ) and oxygen-free copper (18.6×10 -6 ℃ -1 ) There is a large difference in thermal expansion coefficient, and the connection area of the ceramic copper clad laminate is relatively large (common product sizes are 4.5 inches, 6 inches, etc.), and the cold and heat cycle of the ceramic copper clad laminate during use will further lead to residual stress. accumulation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

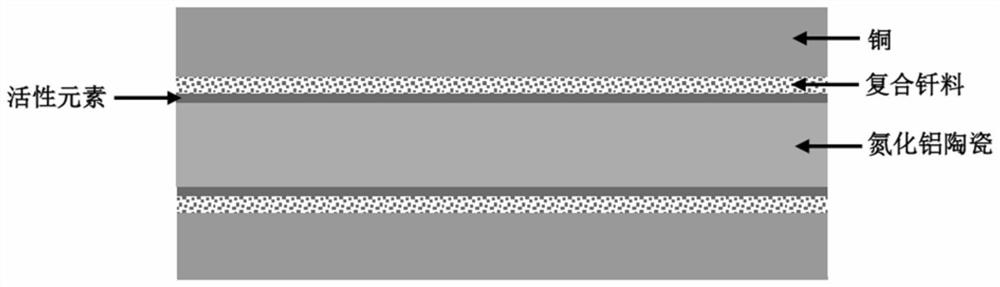

The invention discloses an indirect brazing method for aluminum nitride ceramic copper-clad plates, belonging to the technical field of ceramic copper-clad plates. Preparation process: Mix Ag powder, Cu powder, copper-plated low-expansion ceramic powder and copper-plated graphene powder evenly to prepare composite solder, add organic binder to composite solder to prepare composite solder slurry; Active metal elements Ti, Zr, Hf or Cr are deposited on the surface of aluminum ceramics. After the composite solder is coated on the surface of the aluminum nitride ceramic substrate sputtered with active elements, an oxygen-free copper sheet is compounded on both sides, and the obtained assembly is dried and put into a vacuum furnace for brazing. The invention introduces the ceramic particles with low expansion coefficient into the brazing filler metal, so that the thermal expansion coefficient gradient of the joint is transitioned, thereby significantly reducing the residual stress level of the joint. The invention introduces the graphene with high thermal conductivity and high strength into the composite solder, which can not only increase the strength of the solder but also improve its thermal conductivity.

Description

A kind of indirect brazing method of aluminum nitride ceramic copper clad laminate technical field The present invention relates to ceramic copper clad laminate manufacturing technical field, be specifically related to a kind of indirect brazing of aluminum nitride ceramic copper clad laminate Welding method of manufacture. Background technique [0002] The ceramic copper clad laminate is composed of oxygen-free copper and a ceramic substrate, which takes into account the high conductivity and high conductivity of oxygen-free copper at the same time. Thermal properties and the high insulation and low expansion of ceramic materials are extremely important electronic packaging materials. Power locomotives, aerospace and other fields have broad application prospects. Aluminum nitride ceramics have high thermal conductivity and chemical stability Good and other outstanding advantages, it is a common material for manufacturing high thermal conductivity ceramic copper clad ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K35/22B23K35/24B23K20/14C04B37/02

CPCC04B37/023C04B2237/122C04B2237/125C04B2237/408C04B2237/407C04B2237/52

Inventor 朱巍巍唐木冉旭

Owner CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com