System for extracting effective components of materials

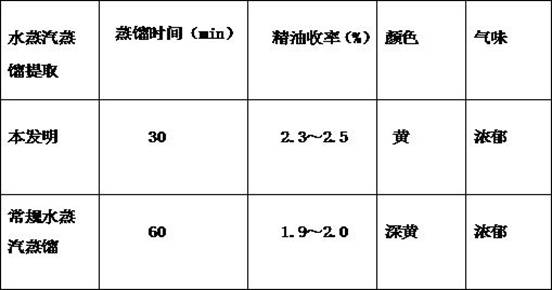

A technology of active ingredients and materials, which is applied in the field of extraction of materials containing aromatic oils, can solve problems such as poor material separation effect, low cooling efficiency, and loss of distillate, and achieve small loss, short distillation time and good quality of distillate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

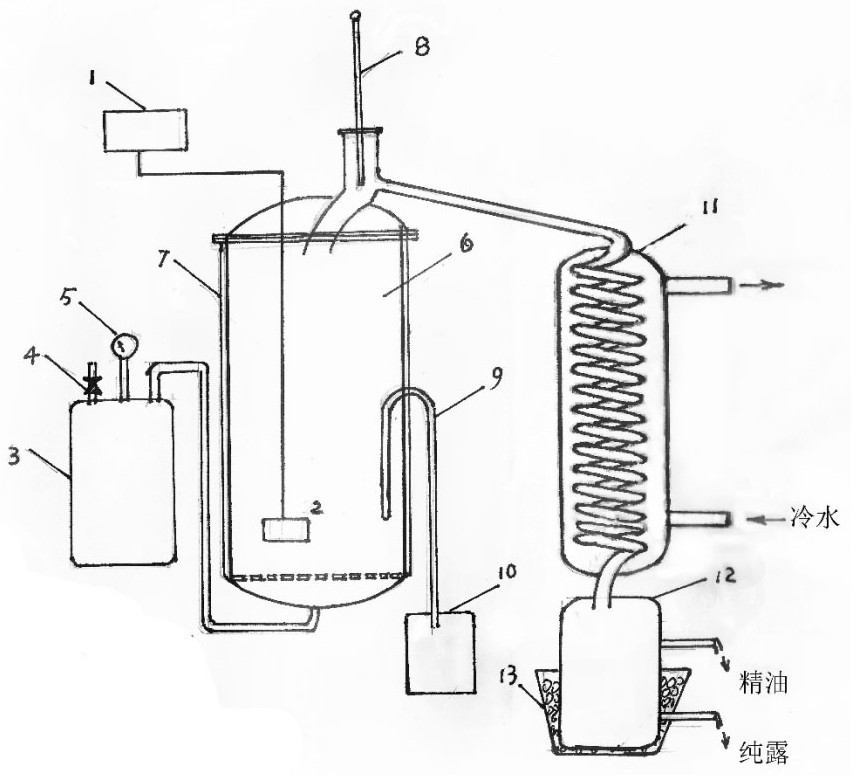

[0023] The system of extracting material active ingredients, the steam generator 3 is connected to the lower end of the distiller 6, and the upper end of the distiller 6 is connected to the upper end of the serpentine, the lower end and the oil water separator 12 of the serpentine 11 through the upper end of the serpentine condenser 11. Connecting, the oil-water separator 12 is located in the ice bath 13, and the ultrasonic transducer 2 of the ultrasonic generator 1 is located in the liquid of the distiller 6, first placed in the distiller 6 to extract the material to inject steady-state active oxygen-rich water. , In the abovement of the material, the ultrasonic transducer 2 is placed in the bottom of the distiller, and the ultrasonic generator 1 is opened, the ultrasonic transducer 2 is preprocessed, and the ultrasonic transducer 2 is removed from the distiller 2, cover The distiller cover, the water vapor generated by the steam generator 3 begins distillation, and the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com