Engine balance shaft arrangement method and structure

A technology for arranging structures and arranging methods, which is applied in the directions of engine components, engine lubrication, machine/engine, etc., can solve the problem that the engine cannot increase the balance shaft configuration, etc., and achieves a wide application range, elimination of positioning accumulation errors, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the specific embodiments in the accompanying drawings.

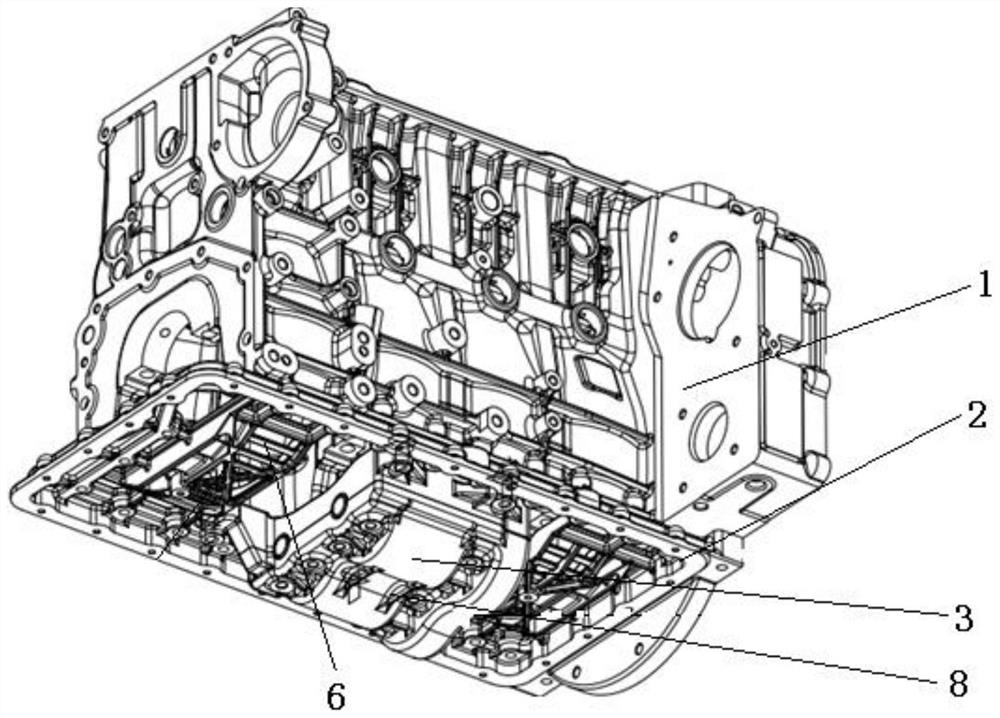

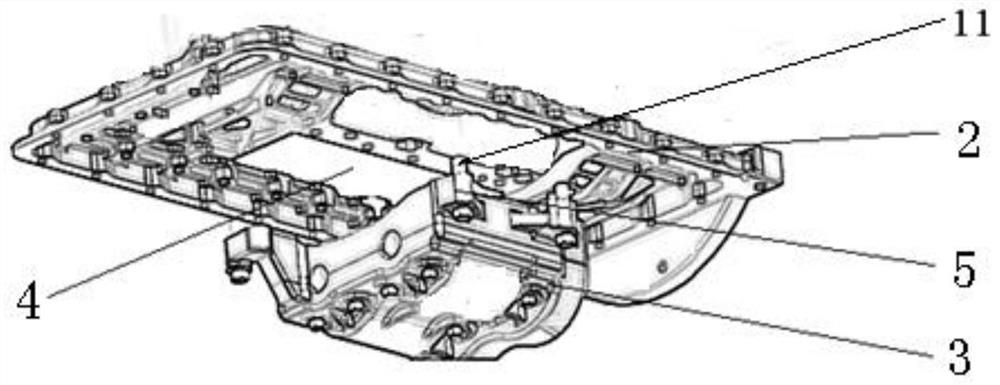

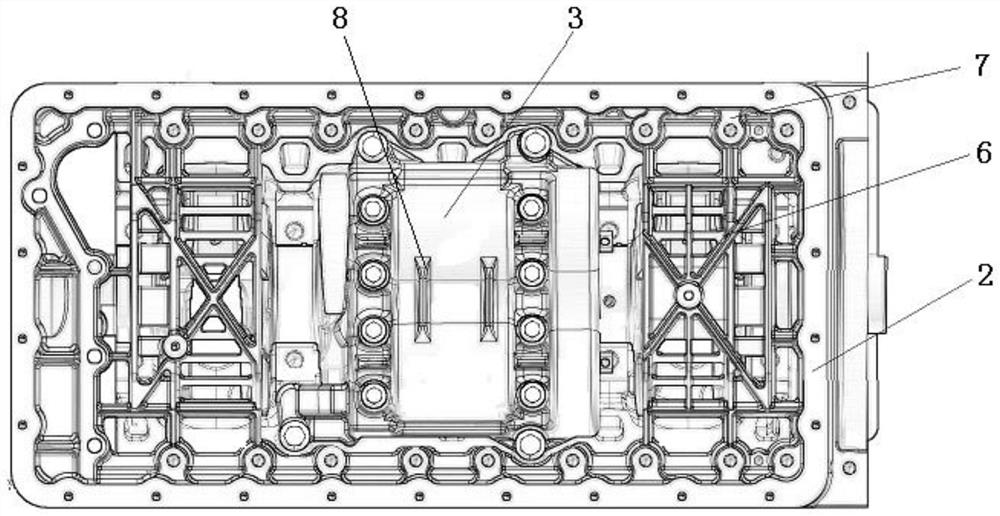

[0022] See Figure 1-4 As shown, the engine balance axis arrangement method is provided, the method is to dispose of the balance shaft system 3 at the bottom of the cylinder block 1, and the balance axis system 3 can be flexibly mount, and it can flexibly forward the oil bottom shell. Down to install.

[0023] Specifically, a reinforcing plate 2 is provided at the bottom of the cylinder block 1, and the balance shaft system 3 is connected to the cylinder block 2, and the reinforcing plate 2 employs a central hollow structure for avoiding the balance shaft system 3 installation space, and also It can also increase the role of overall stiffness of the cylinder skirt.

[0024] A engine balance shaft arrangement of the present invention includes a cylinder block 1 and a balance shaft system 3, and a reinforcing plate 2 is provided at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com