Open air water hole float-and-sink sounding type detonating method

A water hole and sounding technology, applied in the field of blasting, can solve the problems of weakening the explosive power of explosives, easy hole jamming, and reducing the integrity rate of blasting holes, so as to improve blasting efficiency and effect, and prevent water from entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

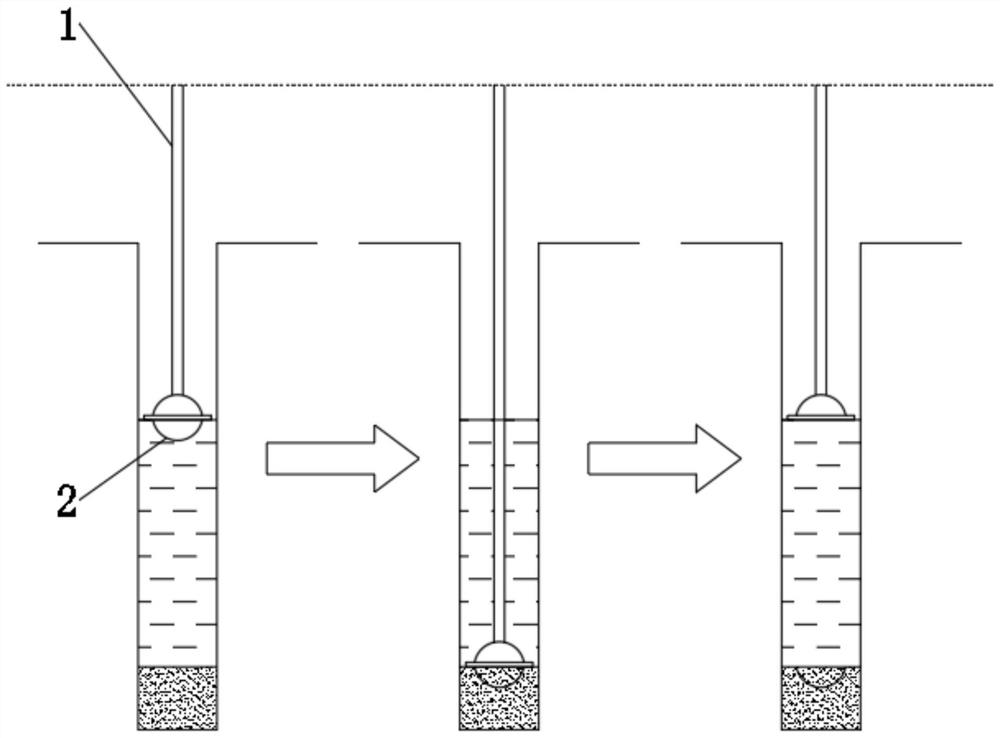

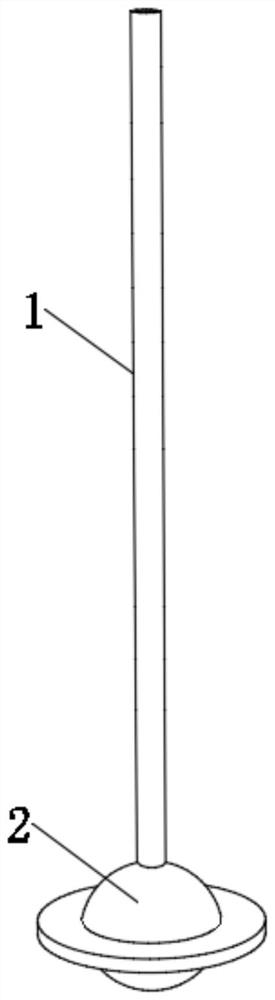

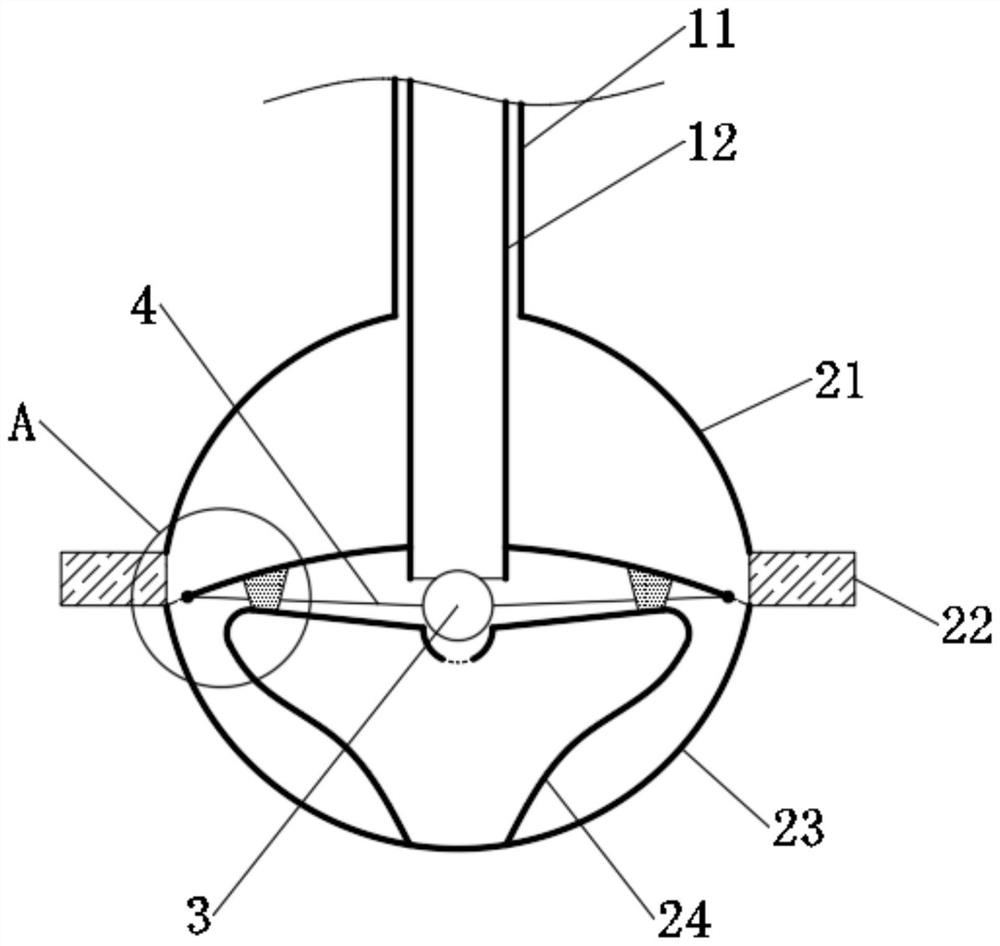

[0047] see Figure 1-2 , an open-air water hole floating and sinking sounding type blasting method, comprising the following steps:

[0048] S1. Screw the double-layer pipe 1 onto the blasting pan 2, lower the blasting pan 2 to the water surface in the water hole, and measure the depth of the air layer;

[0049] S2. Inject counterweight material into the double-layer pipe 1, and then continue to sink to the silt surface in the water hole after the blast sinking pan 2 increases in weight, and measure the depth of the water layer;

[0050] S3. Continue to inject counterweight material into the double-layer pipe 1 until the blast sink pan 2 sinks to the bottom of the water hole, and measure the depth of the mud layer;

[0051] S4. According to the obtained depths of the air layer, water layer and silt layer, reasonably prepare explosive components, and then inject water into the double-layer pipe 1 to force the blasting sinker 2 to separate, the lower half stays in the silt laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com