Method for determining long-term character of shield tunnel rubber sealing gasket

A technology for rubber sealing gaskets and shield tunnels, which is applied in the direction of strength characteristics, the use of stable tension/pressure test material strength, and measuring devices, which can solve the problems of long-term property prediction deviations of shield tunnel sealing rubber gaskets, and achieve The method is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

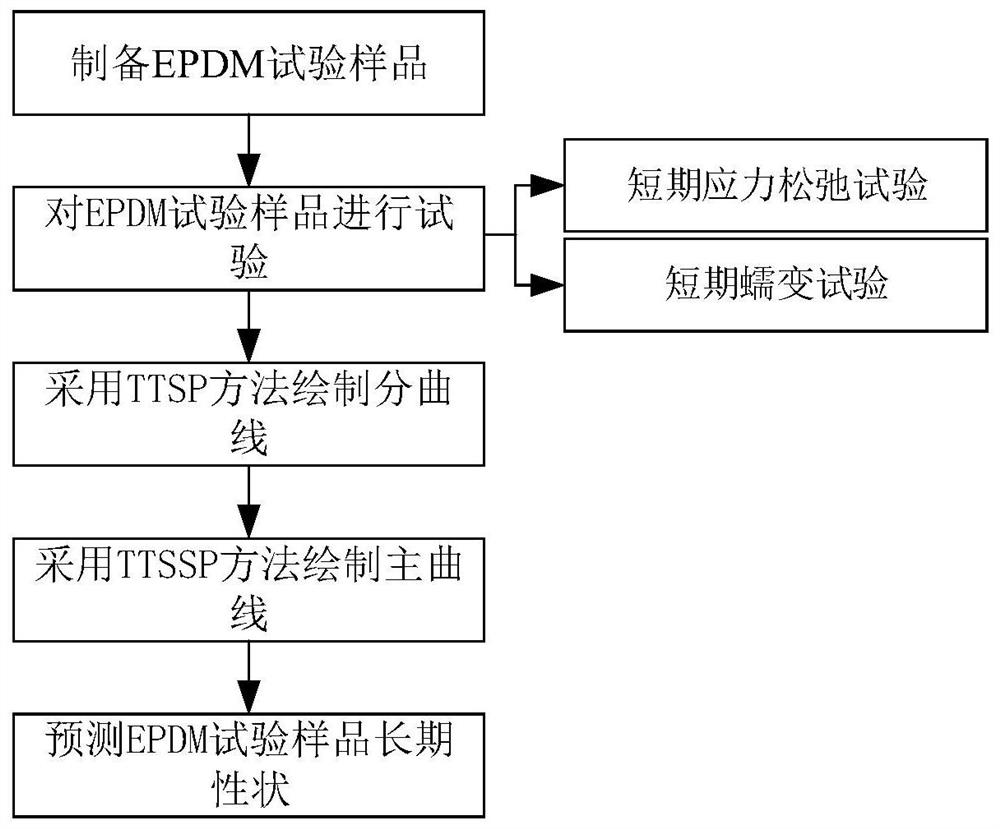

[0038] A method for determining the long-term properties of the shield tunnel rubber gasket provided in this embodiment, the method has the following steps:

[0039] Step 1, prepare EPDM test sample;

[0040] In this embodiment, the EPDM test sample is pretreated by mixing raw rubber, carbon black, calcium carbonate, 300# paraffin oil, calcium oxide, sulfur, stearic acid, zinc oxide and other components in a certain proportion, and then In-situ pre-vulcanization and compression molding, and stored at room temperature for 24 hours, and finally cut into dumbbell-shaped specimens.

[0041] In this embodiment, the weight of the raw rubber is 100phr, and 3092M is used.

[0042]In this example, the weight of the carbon black is 70 phr, N550 is used, and the residue on the 325-mesh sieve is ≤0.1%.

[0043] In the present embodiment, the calcium carbonate is light calcium carbonate with a weight of 20phr and an average particle diameter of 1250 mesh.

[0044] In the present embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com