Solar well lid warning system and detection method

A solar energy and manhole cover technology, which is applied to alarms, measuring devices, geophysical measurements, etc., can solve the problems of manhole cover tilting, inconvenient manhole cover fixing mechanism, easy damage, etc., to reduce damage and reduce road safety problems. , Improve the effect of state control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

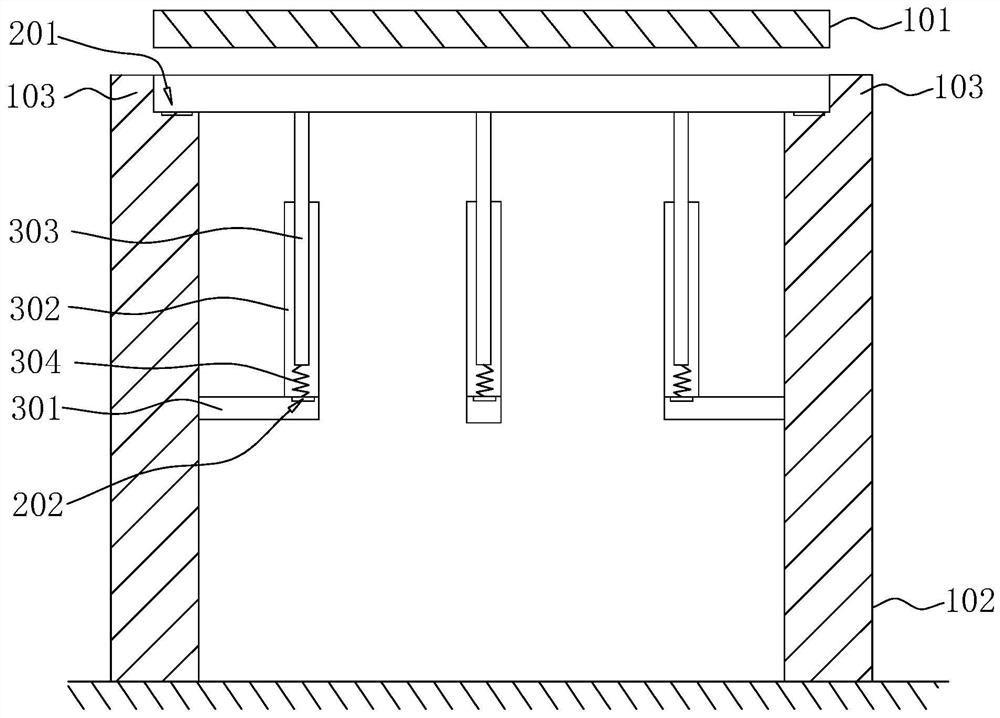

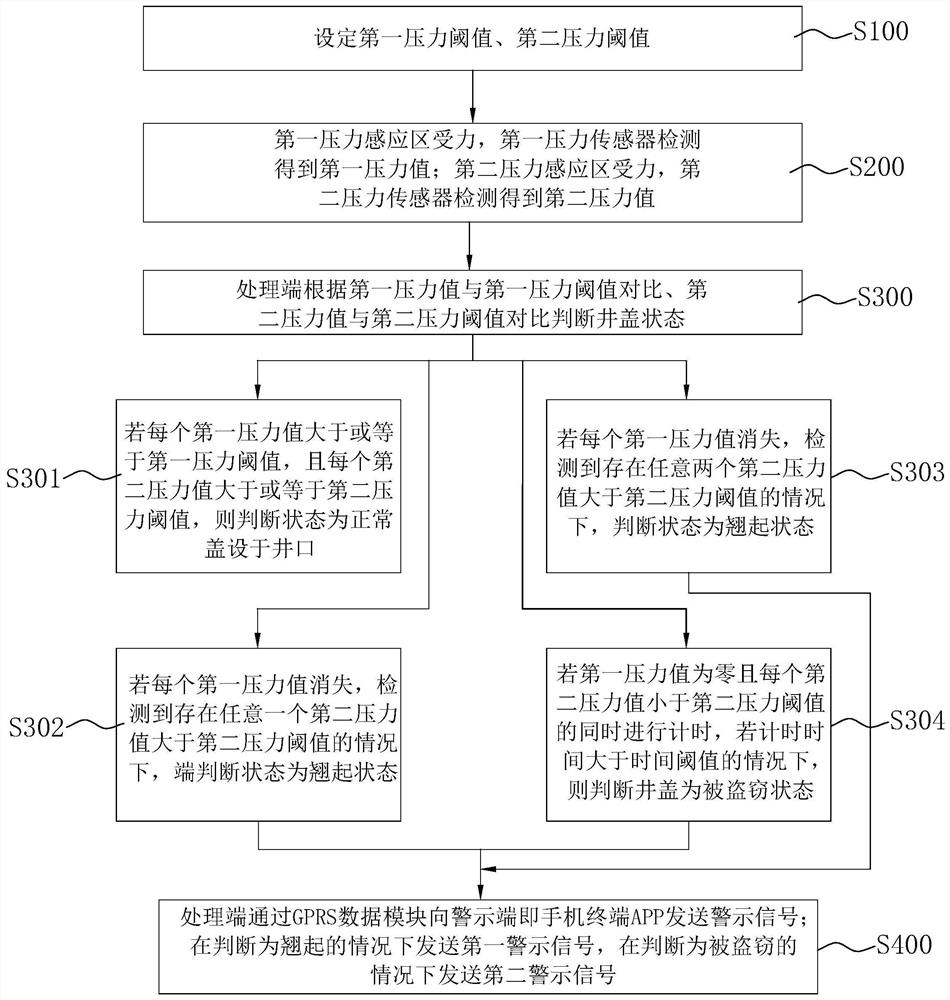

[0060] Such as figure 1 , 2 As shown, the solar manhole cover warning system includes a manhole cover end, a detection end, a warning end and a power supply end.

[0061] Well cover end comprises well body 102, and well body 102 end comprises well body 102, is provided with well cover 101 on the well head of well body 102; 103 is perpendicular to the wellhead and upwards, and the well cover 101 is set inside the Yanbian 103, so that the well cover 101 covers the well head.

[0062] The detection end includes a first detection end and a second detection end;

[0063] The first detection end includes a number of first pressure sensing regions 201 arranged on the edge of the wellhead inside the Yanbian 103. In this embodiment, the number of the first pressure sensing regions 201 is three, which are evenly arranged on the edge of the wellhead inside the Yanbian 103. When the well cover 101 is placed on the well head, each first pressure sensing area 201 is in conflict with the ...

Embodiment 2

[0090] The difference between this embodiment and embodiment 1 is only with:

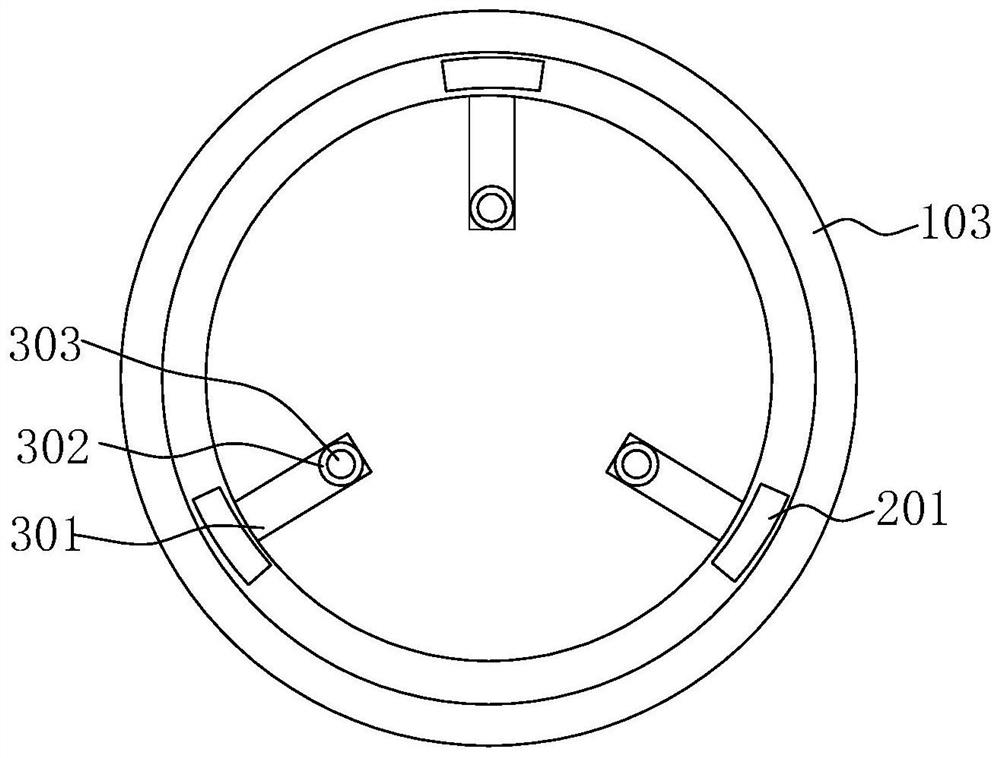

[0091] Such as Figure 4 As shown, the fixing seat includes a pipe body 302 obliquely fixed on the inner wall of the well body 102, the angle between the pipe body 302 and the inner wall of the well body 102 in the counterclockwise direction is 20-30°, and the number of pipe bodies 302 is 3 An isosceles triangle is formed at the connection position between the pipe body 302 and the inner wall of the well body 102, and a conflicting rod 303 is inserted in each pipe body 302, and the bottom end of the conflicting rod 303 is connected to the well body through an elastic reset member 304 On the side wall of the well 102 , there is a second pressure sensing area 202 at the connection position between the inner side wall of the well body 102 and the elastic reset member 304 , and the top of the conflicting rod 303 is in conflict with the lower surface of the well cover 101 .

Embodiment 3

[0093] Such as Figure 5 As shown, on the basis of Embodiment 1, this implementation also adds a function module that reminds the water pressure in the well body 102 to be too large and spray out to cause the well cover 101 to hurt people, such as Figure 4 As shown, it includes a water pressure detection terminal and a water pressure alarm terminal. The water pressure detection terminal refers to the water pressure sensor 401 arranged on the inner wall of the well body 102. The water pressure sensor 401 is connected to a processing terminal. A number of LED402 on Yanbian 103 preset the water pressure preset value in the processing end, and when the water pressure value detected by the water pressure sensor 401 is greater than the water pressure preset value, the processing end controls the water pressure alarm end to make an alarm , that is, the LED402 is blinking, and also includes a solar cell, which is used to supply power to the water pressure detection terminal and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com