A task collaborative planning method and system for smart factories

A task and factory technology, applied in the field of data processing, can solve the problems of large information security threats, increased transmission costs, lack of parallel execution methods for artificial intelligence tasks, etc., to reduce production costs, reduce delays and energy consumption, and realize The effect of sensitive needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

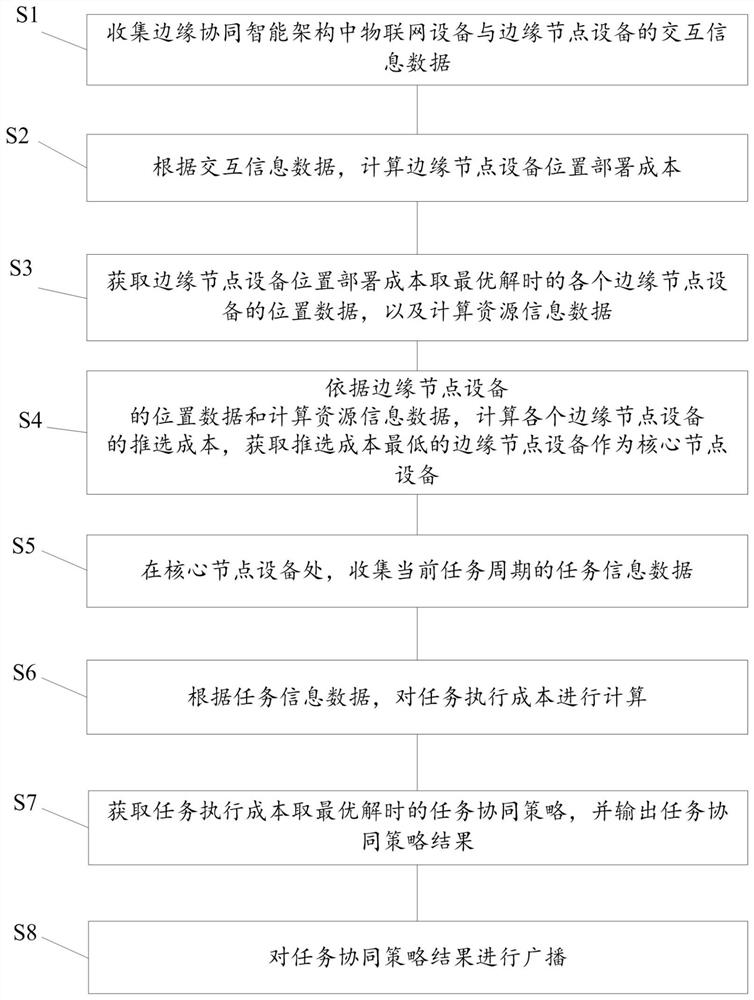

[0060] Such as figure 1 As shown, the present application provides a method for collaborative task planning for smart factories, which includes the following steps:

[0061] Step S1, collecting interaction information data between IoT devices and edge node devices in the edge collaborative intelligent architecture.

[0062] Establish an ad hoc network in the edge node network in advance, build an edge collaborative intelligent architecture based on the ad hoc network, set the ad hoc network composed of M edge node devices that can be used for task computing in the edge node network, and set the task collaboration strategy update The period is T S , at period T S There are K Internet of Things (IoTs) devices in China.

[0063] A virtual cloud based on an ad hoc network does not need to rely on a remote server, but a group of mobile devices cooperate to calculate and complete tasks.

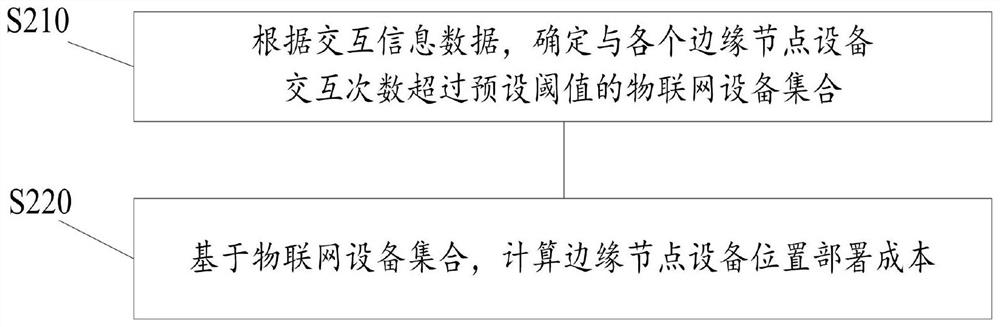

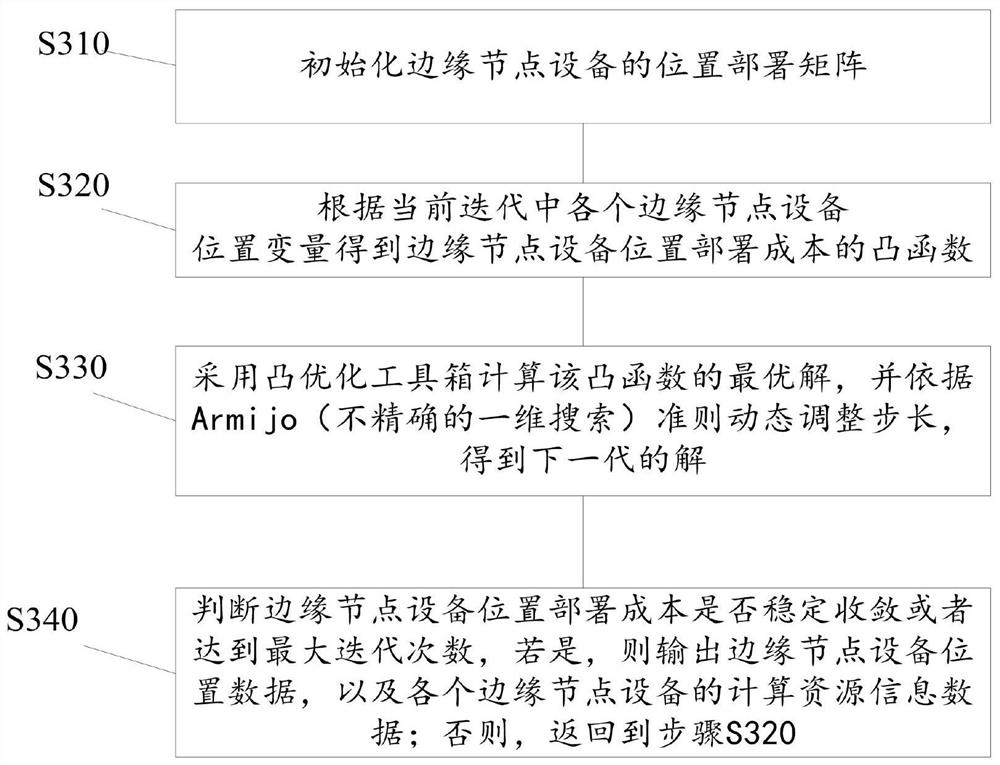

[0064] Define the total system cost in the edge collaborative intelligent architecture as f...

Embodiment 2

[0117] Such as Figure 5 and 6 As shown, the present application provides a smart factory-oriented task collaborative planning system 100, the system includes: an edge collaborative intelligent architecture 10 based on an ad hoc network, and the edge collaborative intelligent architecture 10 includes a plurality of IoT devices 11 and a plurality of edge nodes A device 12; a plurality of IoT devices 11 and a plurality of edge node devices 12 are communicatively connected; a plurality of edge node devices 12 perform task coordination.

[0118] A data collection device 20, configured to collect interaction information data between the IoT device and the edge node device in the edge collaborative intelligent architecture;

[0119] The data processor 30 is configured to calculate the location deployment cost of the edge node device according to the interaction information data;

[0120] The obtaining module 40 is used to obtain the location data of each edge node device and compu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com