A printer nozzle movement adjustment device

A motion adjustment and printer technology, applied in printing devices, power transmission devices, printing and other directions, can solve the problems of difficult control of the movement stability of the printing carriage, difficult to ensure the accuracy of the overall angle adjustment, and large occupied area of the X-axis transmission device. Save labor cost, compact structure, good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

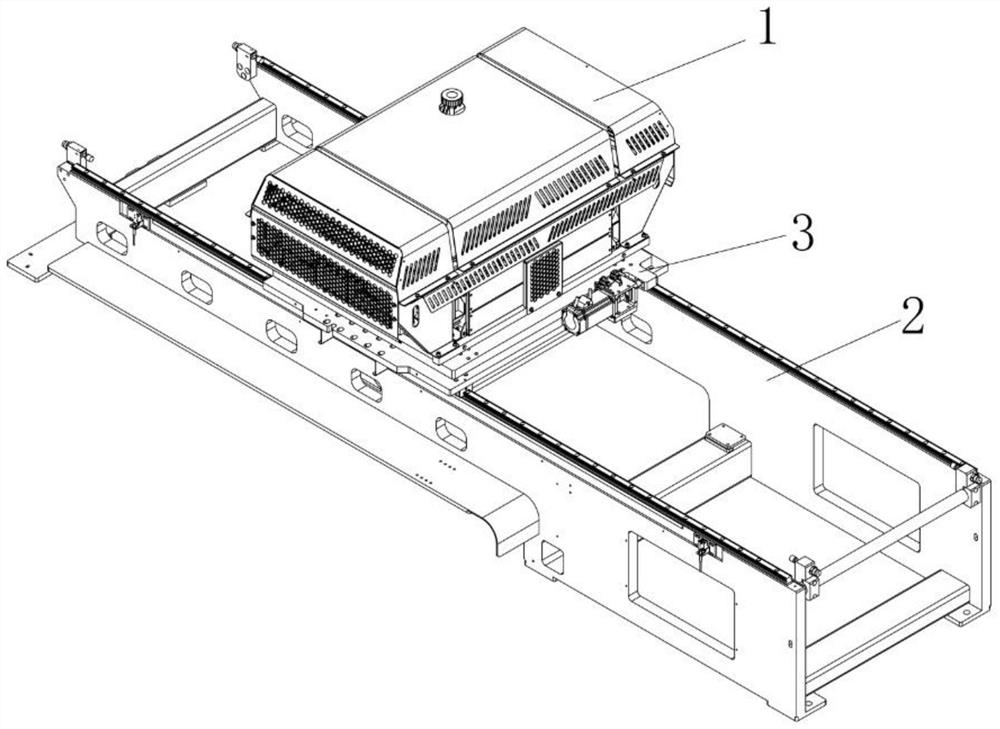

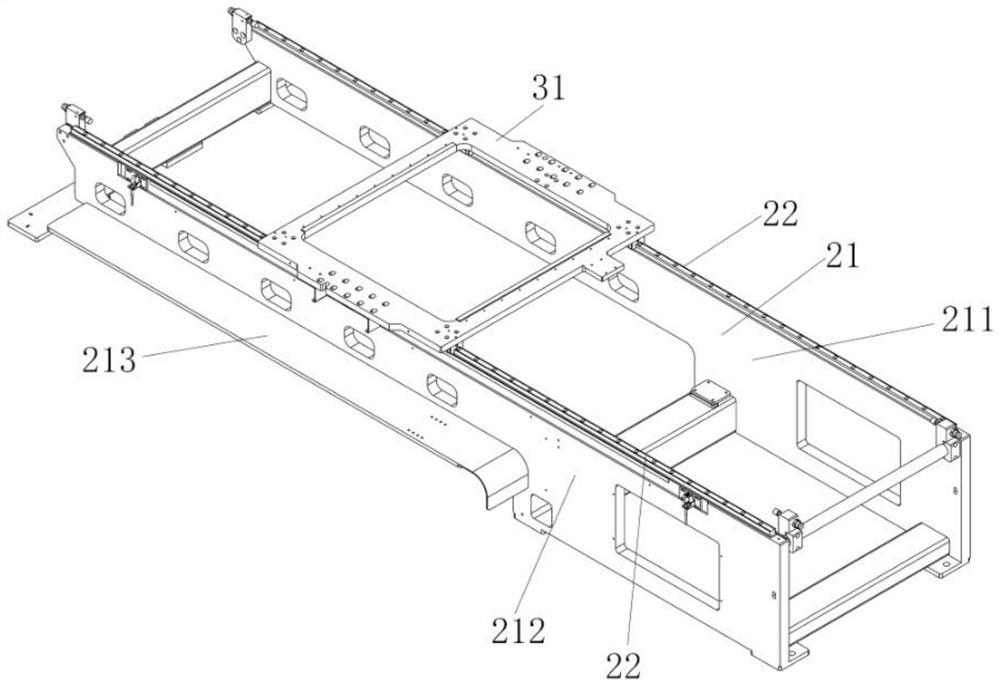

[0049] refer to figure 1 and figure 2 As shown, a printer nozzle movement adjustment device, the improvement of which is that it includes a printing cart 1, a Y-axis transmission device 3 that carries the printing cart 1 and drives the printing cart 1 to move along the Y axis, carries the printing cart 1 and the The Y-axis transmission device 3 and the X-axis transmission device 2 that drives the printing cart 1 and the Y-axis transmission device 3 to move along the X-axis; the X-axis transmission device 2 includes the printing cart 1 and the Y-axis transmission device 3 The main frame 21, the first control device 24 for controlling the movement and movement position of the printing carriage 1 and the Y-axis transmission device 3, the first guide installed above the main frame 21 and guiding the movement of the printing carriage 1 device; the main frame 21 includes a first side plate 211 and a second side plate 212 on both sides and a support beam between the first side plat...

Embodiment 2

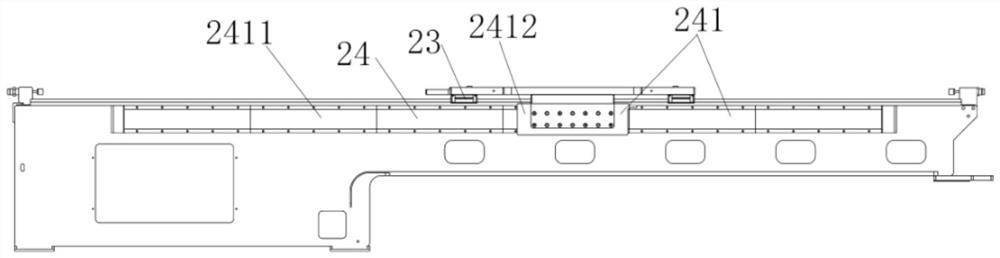

[0056] On the basis of embodiment 1, with reference to image 3 As shown, the first control device 24 includes a linear motor 241 for driving the Y-axis transmission device 3 to move, and a position detection device 242 for detecting the moving position of the Y-axis transmission device 3 .

[0057] Further, the linear motor 241 includes a linear motor stator 2411 mounted on the side of the first side plate 211 or the second side plate 212, mounted on one side of the Y-axis transmission device 3 and connected to the linear motor stator 2411 a linear motor mover 2412 that cooperates with each other; the position detection device 242 includes a magnetic grid 2421 installed on the side of the first side plate 211 or the second side plate 212, a magnetic grid installed on the Y-axis transmission device 3 Grid read head 2422.

[0058] In this embodiment, the linear motor 241 has the advantages of simple structure, high positioning accuracy, fast response, high sensitivity, good fo...

Embodiment 3

[0060] On the basis of embodiment 2, with reference to Figure 4 As shown, the first control device 24 includes a safety travel control device 243 for defining the start position and end position of the travel of the Y-axis transmission device 3, which is arranged on the first side plate 211 or the second side plate The anti-collision device 244 at the limit position of the Y-axis transmission device 3 on the 212; the safety travel control device 243 includes a position sensor 2431, and the Y-axis transmission device 3 is equipped with a sensor stopper that matches the position sensor 2431. Sheet II 2432 ; the anti-collision device 244 includes an anti-collision block 2441 and a buffer member 2442 mounted on the anti-collision block 2441 and facing the Y-axis transmission device 3 .

[0061] In this embodiment, when the sensor stopper II2432 reaches the position of the position sensor 2431, the sensor will transmit a signal to the linear motor 241, thereby stopping the movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com