Corrugated paper stacking and transporting vehicle assembled based on order requirements and control method thereof

A control method and technology for transporting vehicles, which can be applied to conveyor control devices, object stacking, conveyors, etc., can solve problems such as inflexibility and convenience, increasing assembly-loading processes, and consuming human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

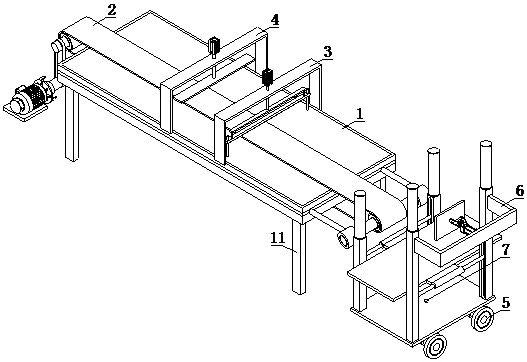

[0042] see figure 1 , a corrugated paper stacking transport vehicle assembled based on order requirements and a control method thereof, comprising a transport device 5, a stacking device 6 is disposed on the transport device 5, a control system 7 is disposed above the transport device 5, and the control system 7 They are electrically connected to the stacking device 6 and the conveying device 5 respectively.

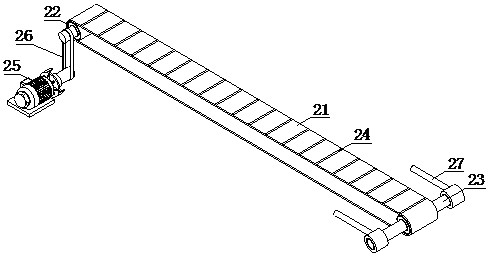

[0043] see figure 2 , the conveying device 2 includes a conveying chain belt 21, a conveying shaft 22, an inner shaft rod 23, an anti-slip layer 24, a conveying motor 25, a synchronous belt 26, and a mounting rod 27, and the outer surface of the conveying chain belt 21 is covered with an anti-slip layer 24 , the inner two ends of the conveyor chain belt 21 are covered with a conveying shaft 22, the inner shaft of the conveying shaft 22 is sleeved with the inner shaft 23, and the two ends of the inner shaft 23 are connected with the installation rod 27 through the socke...

Embodiment 2

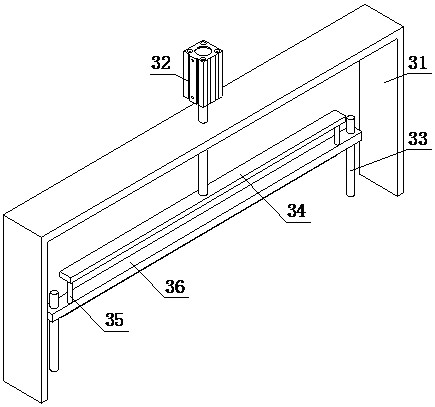

[0050] see Figure 13, the stacking device 6 includes a placement mobile assembly 61 and a pressure guide assembly 62, the pressure guide assembly 62 is installed above the placement mobile assembly 61, the placement mobile assembly 61 is fixed above the transport device 5, and the placement mobile assembly 61 includes a fixed column 611, Tray body 612, docking ring 613, connecting shaft 614, mobile motor 616, chute 615 and lifting cylinder 617, fixed column 611 is fixed at the four corners above the transport device 5, and chute 615 is set on the inner end surface of fixed column 611, A connecting shaft 614 is set through the chute 615, and one end of the connecting shaft 614 is connected to the moving motor 616. The tray body 612 is arranged between the fixed columns 611. The two ends of the tray body 612 are respectively equipped with docking rings 613, and the docking rings 613 are sleeved on the On the connecting shaft 614, and the inner end surface of the docking ring 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com