Method for enhancing methane production efficiency of anaerobic digestion of wastewater sludge by coupling electric field with Fe-C composite mediator

A composite media and wastewater sludge technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of limited methane performance, easily inhibited methane production, long reaction time, etc. problem, to achieve the effect of increasing flocculation strength, increasing methane production rate, and increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

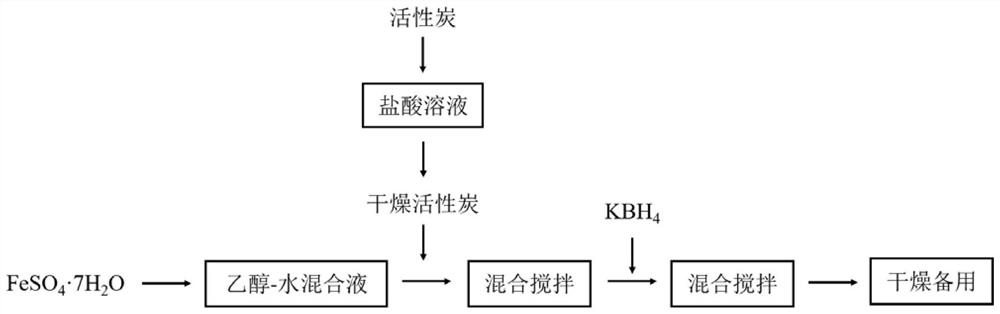

Method used

Image

Examples

Embodiment 1

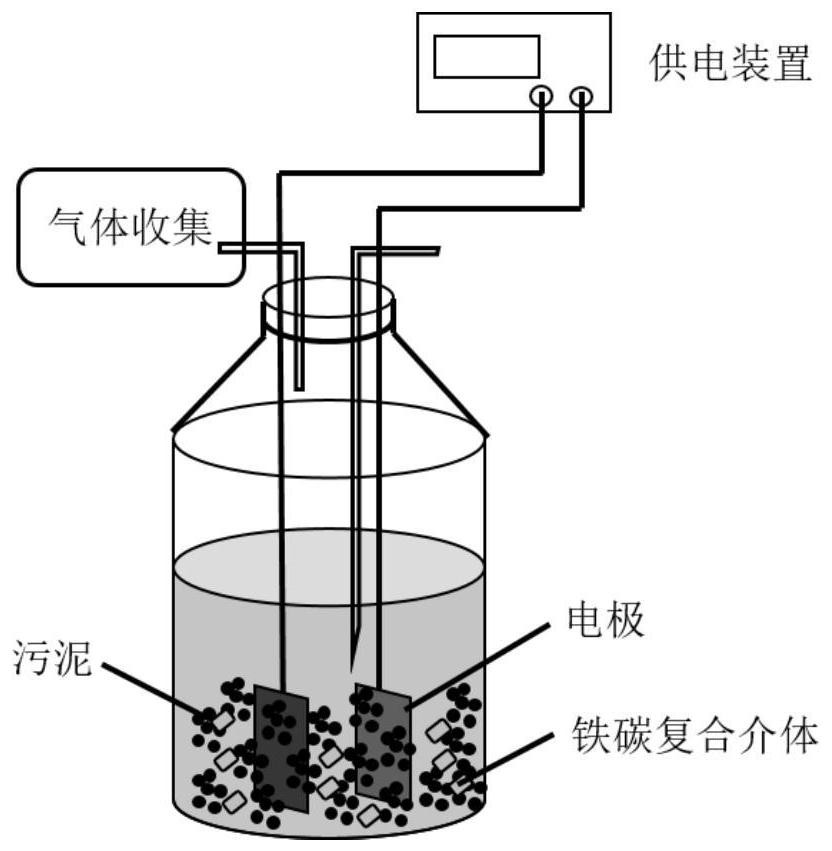

[0038] The iron-carbon composite material prepared above is coupled with an electric field to treat anaerobic wastewater, and the enhanced treatment steps are as follows:

[0039] ①Add 20mL of anaerobic sludge and 80mL of wastewater into the anaerobic bottle, and the headspace is 30mL. And add 100mg iron-carbon composite mediator.

[0040] ②Connect a steel needle with a three-way valve for sampling and an air bag to the anaerobic bottle for liquid sampling and gas collection.

[0041] ③Using titanium meshes as electrodes (the distance between the titanium meshes is 2cm, and the size is 1.5cm*1.5cm), connect with the potentiostat through titanium wires, and apply a constant potential of 0.10V to the reactor.

[0042] ④ Connect the anaerobic bottle and place it in a constant temperature shaker. Control the temperature of the constant temperature shaker at 35±1°C and keep the rotation speed at 95r / min.

[0043] During the operation of the anaerobic reaction, the liquid and gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap