Diagonally braced offshore wind power monopile foundation with damping sleeve and its construction method

A technology for offshore wind power and single-pile foundations, which can be used in infrastructure engineering, wind power generation, sheet pile walls, etc., and can solve problems such as reducing the diameter of piles, complex transportation and installation, and high manufacturing and installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

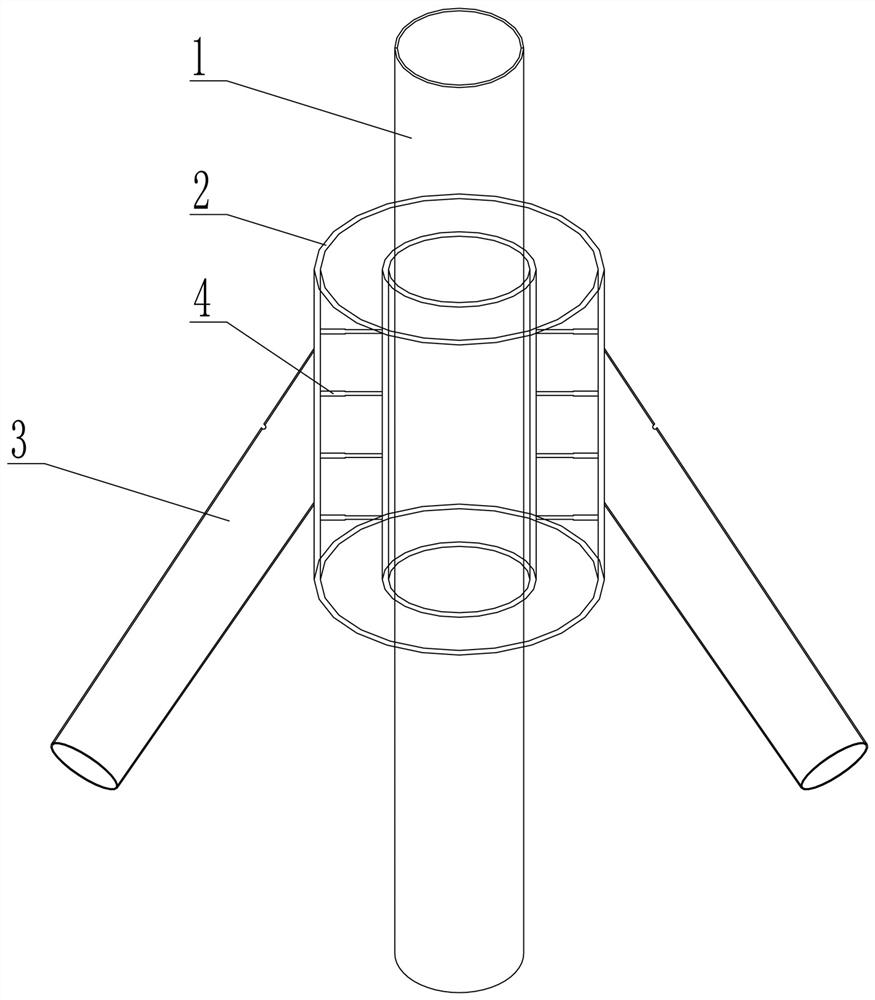

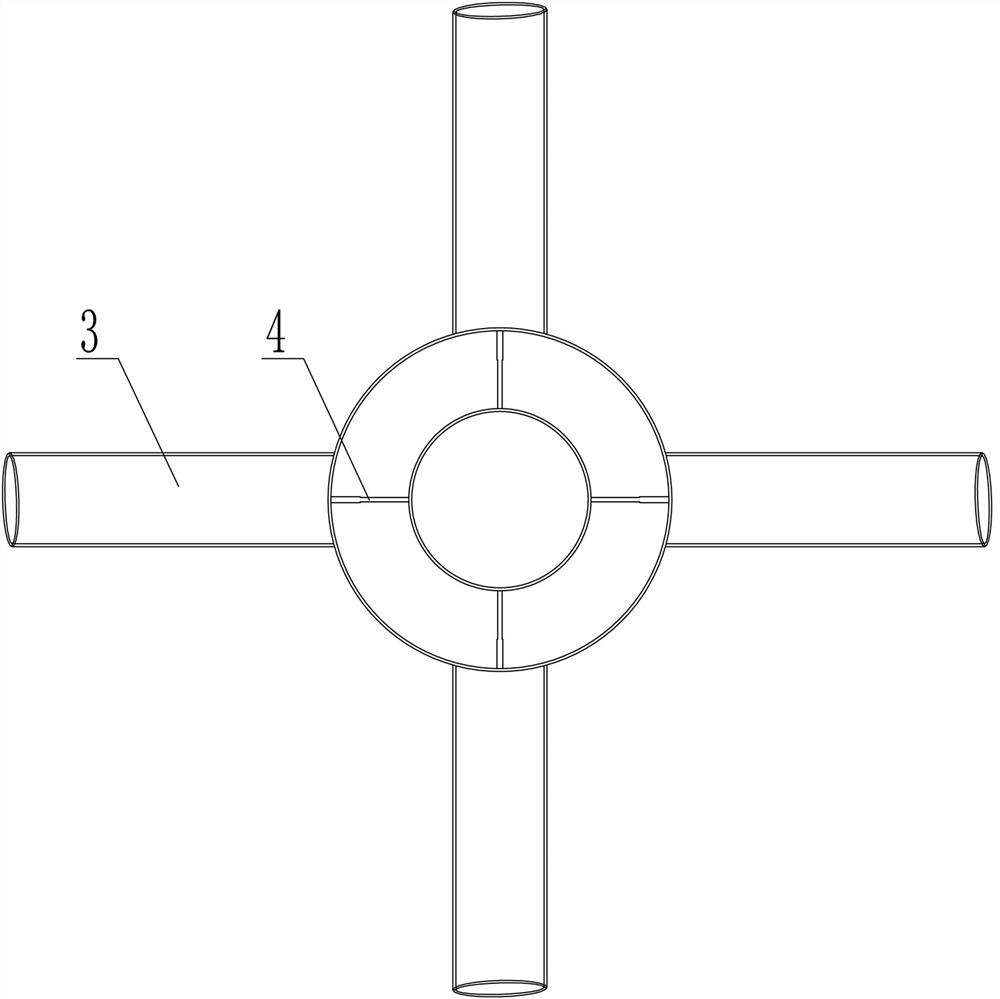

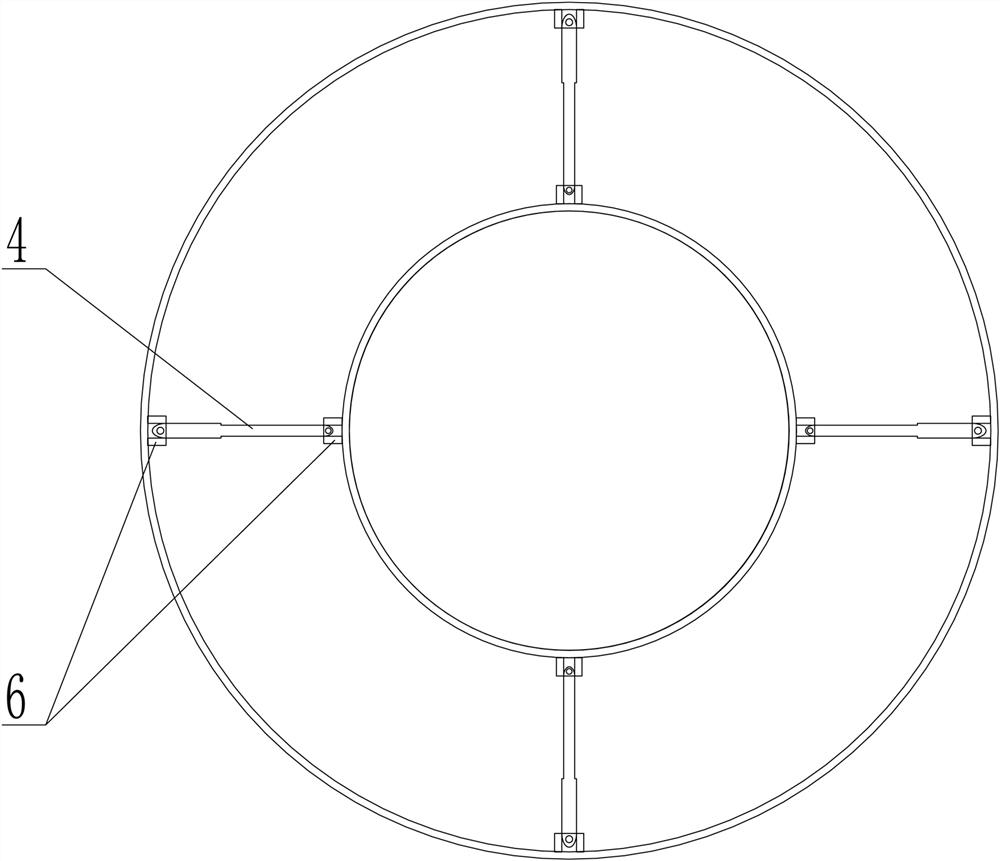

[0027] as Figure 1 to Figure 5In the middle, a kind of inclined support offshore wind power monopile foundation with damping sleeve, which includes pile body 1, damping sleeve 2 and oblique bracing 3, damper 4 and rotating shaft 5; The oblique bracing 3 is connected to the damping sleeve 2, and the plurality of diagonal bracings 3 are laid radially along the outer wall of the damping sleeve 2; Damper 4 is arranged inside the damping sleeve 2, the rotating shaft 5 is connected with the damping sleeve 2 and damper 4; The axis direction of the damping sleeve 2 is consistent with the axis direction of pile body 1; Set the filler between the damping sleeve 2 and the pile body 1; Damper 4 four-way translational. The structure is simple, during construction, multiple inclined bracings 3 along the outer wall of the damping sleeve 2 are annular radial layout, the viscous damper is laid out inside the damping sleeve 2 and connected with the rotating shaft 6 to achieve four-way translation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com