Primary support structure and method for controlling surrounding rock deformation through preexpansive force

A technology of surrounding rock deformation and initial support, applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve problems such as breaking the stress balance state, and achieve the effect of suppressing creep, ensuring long-term safety, and being able to withstand bending moments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

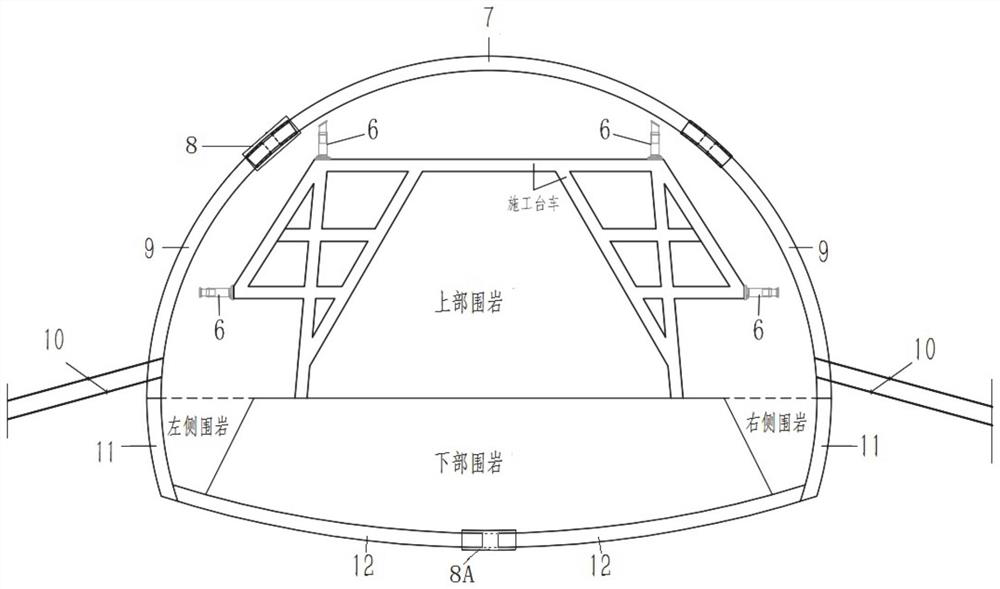

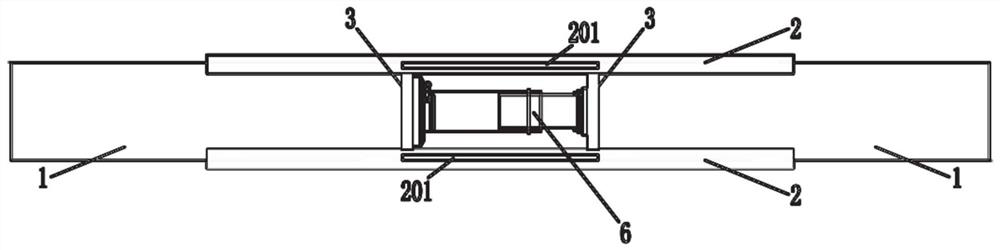

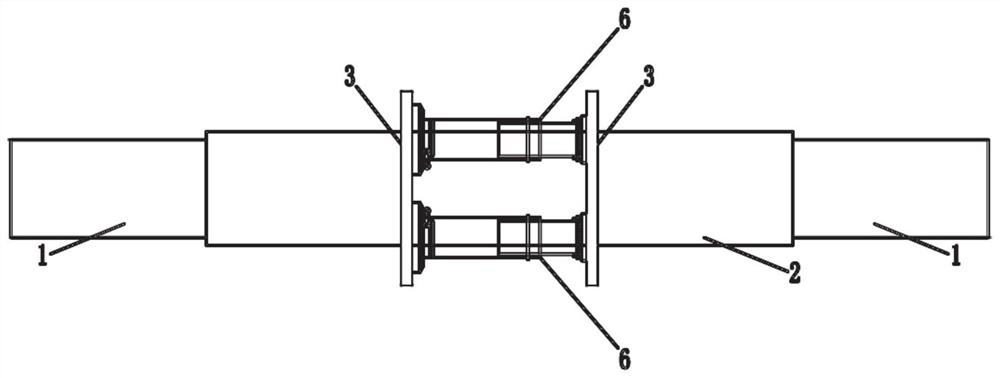

[0032] like Figure 1-Figure 5 As shown in Fig. 1 , a primary support structure for the pre-expansion force to control the deformation of the surrounding rock is given, including the top section steel, the two ends of the top section steel are respectively connected with the side section steel, and the top section steel and the side section steel are combined into an arch steel The lower end of the side section steel is connected to the arch feet, and an inversion is set between the two arch feet. The sleeve is connected, and the side wall of the sleeve is provided with a gap, which is used to take and place the jack into the inner cavity of the sleeve; the inner cavity of the sleeve can place a support plate through the gap, and the support plate can fill the space after the jack is taken out, and the support plate can be connected with the sleeve The cylinder is fixed to maintain the prestress of the arch steel frame, arch feet and inverted arches on the surrounding rock.

...

Embodiment 2

[0041] This embodiment provides a primary support method for controlling the deformation of the surrounding rock by the pre-expansion force. The primary support structure for controlling the deformation of the surrounding rock by using the pre-expansion force described in Example 1 includes the following steps:

[0042] Excavate the surrounding rock of the upper part of the tunnel, assemble the top section steel 7, the sleeve 2 and the inverted arch section steel 12 to form an arched steel frame;

[0043] The arched steel frame is lifted by the construction trolley until the outer wall surface is in contact with the inner wall of the tunnel, and the jack 6 is lifted up, so that under the set jacking pressure, the end surface distance between the top section steel 7 and the side section steel 9 is enlarged to the maximum value;

[0044] Fix the top section steel 7, the side section steel 9 and the sleeve 2, and fix the lower part of the side section steel 9 to the side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com