Anti-freezing secondary refrigerant recycling device for central air-conditioning system of energy tower

A technology for central air-conditioning systems and refrigerants, applied in refrigerants, refrigerators, refrigeration components, etc., can solve the problems of rising energy management costs, cumbersome replacement of antifreeze, and difficulty in reuse, etc., to improve intelligence and convenience. The effect of improving the durability, improving the service life, and preventing the problem of abandonment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

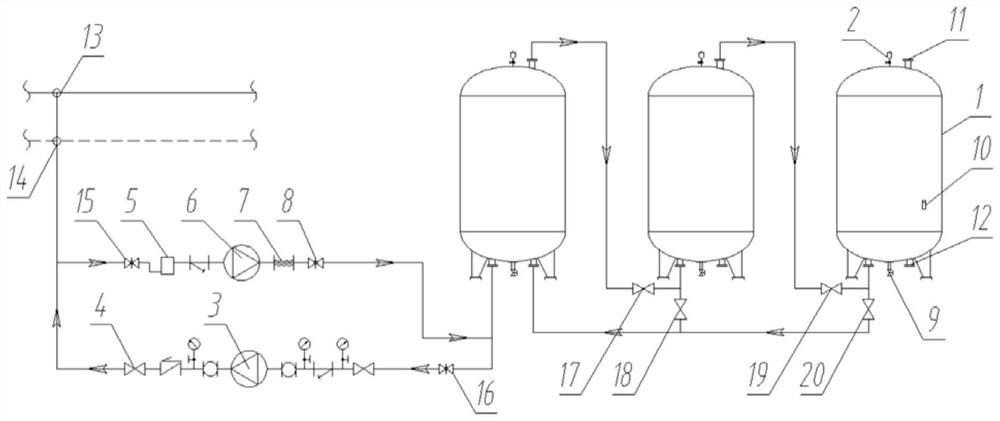

[0018] like figure 1 As shown in the figure, a recovery and reuse device for antifreeze refrigerant used in an energy tower central air-conditioning system includes at least one liquid storage tank 1, and an automatic exhaust valve 2 is provided on the liquid storage tank 1, and the liquid storage tank 1 is provided with an automatic exhaust valve 2, respectively. A first interface 11 and a second interface 12 are provided, the liquid storage tank 1 is provided with a solution concentration meter 10, the bottom of the liquid storage tank 1 is provided with a drain valve 9, and the liquid storage tank 1 is connected with the central air conditioning cooling recovery pipe through a recovery pipeline The liquid storage tank 1 is communicated with the central air-conditioning cooling supply pipe through the supply pipeline, the supply pipeline is provided with a solution supply pump 3, and a second valve 16 and a cut-off valve are respectively provided on the supply pipeline at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com