Pressure gauge and rapid calibration method and pressure calibration device thereof

A pressure gauge and fast technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of leakage of working medium, residue, and manufacturing consistent sealing means can not achieve the sealing effect, so as to improve work efficiency and reduce gas pressure. The effect of reducing the risk of road leakage, ensuring sealing and working continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

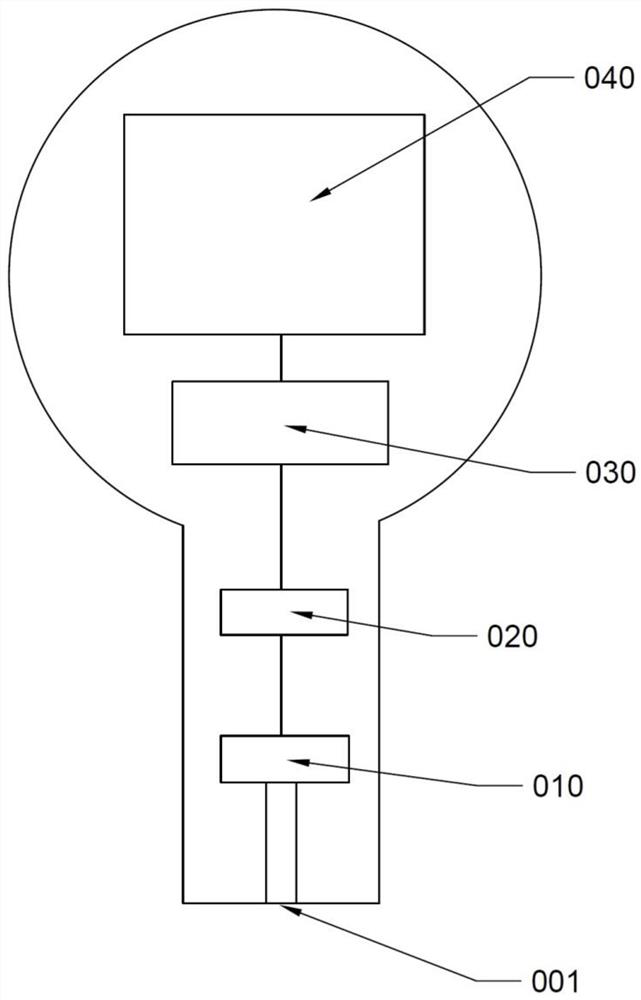

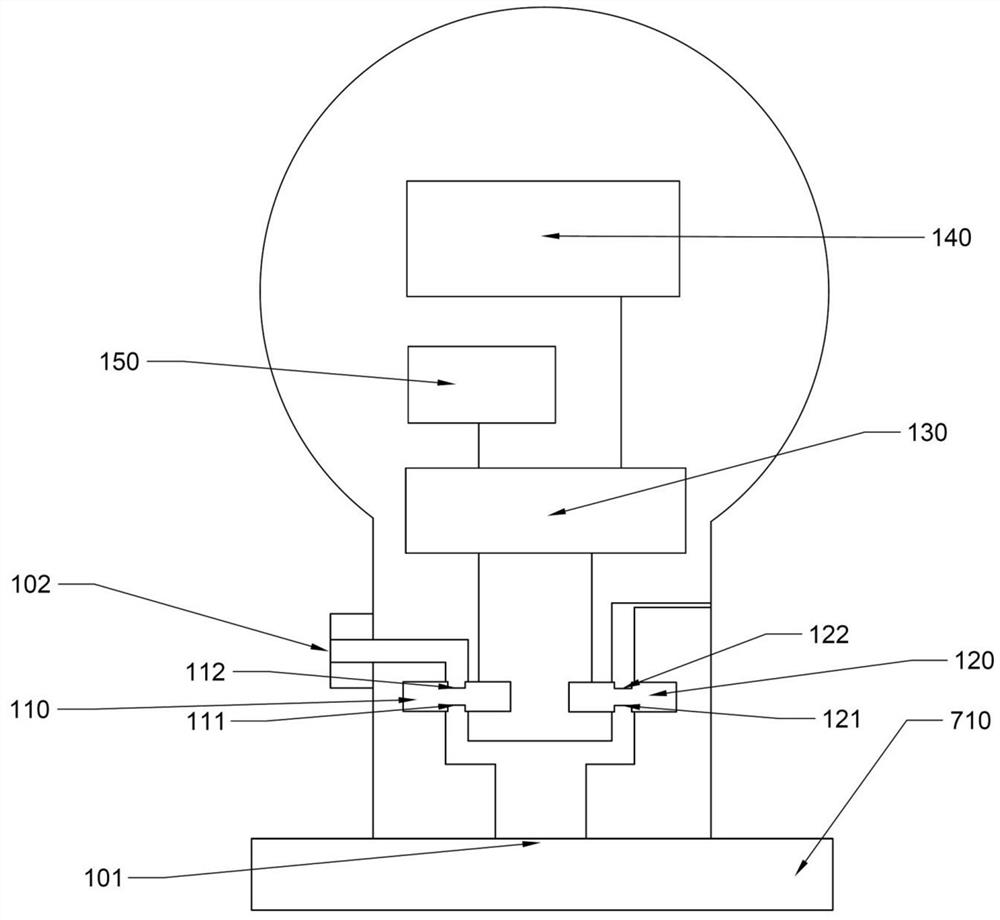

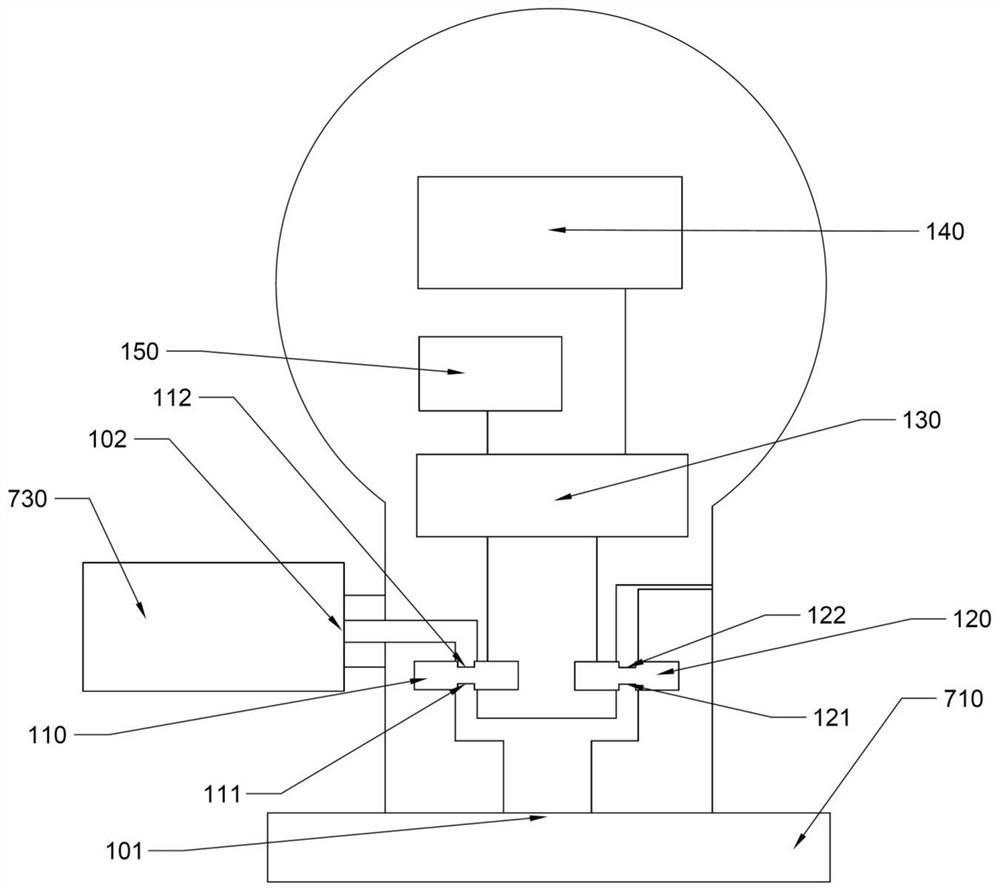

[0056] example, such as figure 2 as well as image 3 As shown, a pressure gauge includes a first pressure sensor 110 , a second pressure sensor 120 , a working pressure port 101 and a quick calibration pressure port 102 .

[0057] The first pressure sensor 110 includes a first pressure-sensing surface 111 and a second pressure-sensing surface 112, the first pressure sensor measures the relative pressure of the first pressure-sensing surface and the second pressure-sensing surface and generates a pressure signal;

[0058] The second pressure sensor 120 includes a first pressure-sensing surface 121 and a second pressure-sensing surface 122, the second pressure sensor measures the relative pressure of the first pressure-sensing surface and the second pressure-sensing surface and generates a pressure signal;

[0059] The working pressure interface 101 is used to communicate with the measured pressure source, so that the first pressure sensor and the second pressure sensor can me...

specific Embodiment 2

[0110] example, such as Figure 6 As shown, the pressure gauge includes a gauge head 303 and a pressure acquisition module 304;

[0111] The front of the meter head 303 is provided with a display screen 340 for displaying pressure value information. The inside of the meter head 303 is provided with a processing module 330 for information processing. The fixed structure 305 and the signal connection part 306, the fixed structure is used to fix the meter head and the pressure acquisition module, the signal connection part is used to establish a signal connection with the pressure acquisition module, and the processing module 330 is respectively connected to the signal connection part 306 and the pressure acquisition module of the meter head. Display screen 340 signal connection.

[0112] The lower end surface of the pressure acquisition module 304 is provided with a working pressure port 301, and when a pressure gauge is used for pressure measurement, the working pressure port ...

specific Embodiment 3

[0200] example, such as Figure 10 and Figure 11 As shown, the pressure gauge includes a casing, a display screen 440 is arranged on the front of the casing, a working pressure port 401 is arranged on the bottom of the casing, and a quick calibration pressure port 402 is arranged on the lower part of the back of the casing.

[0201] The pressure sensor 410 is fixed inside the housing and includes a first pressure-sensing surface 411 and a second pressure-sensing surface 412. The first pressure-sensing surface 411 communicates with the working pressure interface 401, and the second pressure-sensing surface 412 communicates with the quick calibration pressure interface. 402 is connected, and the pressure sensor 410 measures the relative pressure of the first pressure-sensing surface and the second pressure-sensing surface, and generates a pressure signal (analog electrical signal) indicating the relative pressure value.

[0202] What is connected with the pressure sensor signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com