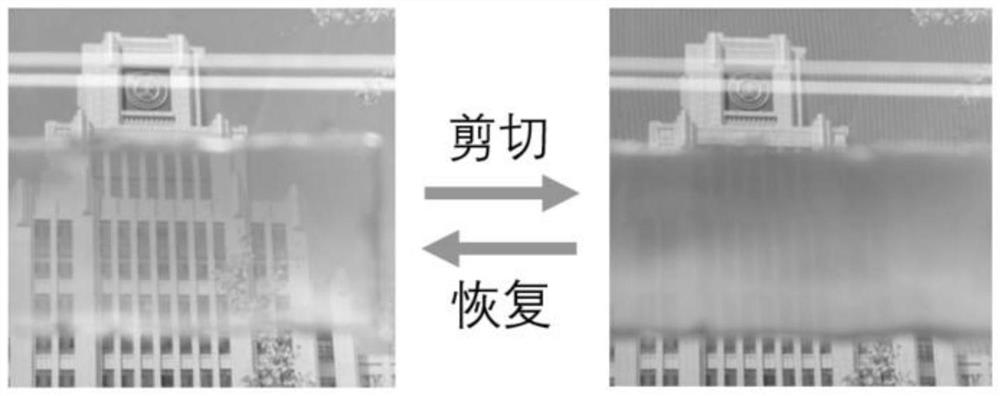

Flexible film with light transmittance capable of being regulated and controlled through shear strain and preparation method of flexible film

A flexible film and capability technology, applied in the field of windows and their preparation, can solve problems such as excessively fast materials, increased flexibility of mechanical systems, and limited application occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

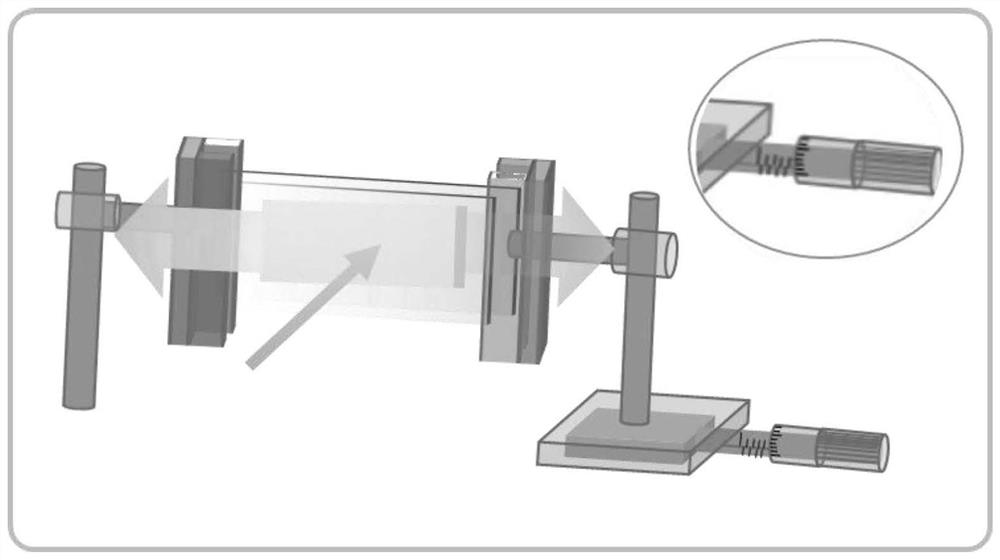

[0080] In another embodiment, the present invention also discloses a method for preparing the flexible film, comprising:

[0081] One-dimensional magnetic nanochains were prepared by using a magnetic assembly method, and then the nanochains were oriented distributed in a polyacrylamide (PAM) precursor solution under the assistance of a magnetic field, and the nanochain / polyacrylamide composite flexible film was obtained after ultraviolet curing.

[0082] In another embodiment, the present invention also discloses a method for preparing the flexible film, comprising:

[0083] The first step, the preparation of magnetic nanochains:

[0084] The superparamagnetic nanoparticles were dispersed in the ethanol / ammonia water mixed solution, and tetraethyl orthosilicate (TEOS) was added dropwise to the solution to hydrolyze and deposit SiO on the surface of the magnetic particles. 2 Coating layer; by applying a magnetic field, the nanoparticles are aligned under the action of the magn...

Embodiment 1

[0098] Embodiment 1: A method for preparing a flexible film with controllable light transmission under shear strain, specifically comprising the following steps:

[0099] Ⅰ. Preparation of magnetic field-assisted nanochains: 10 mg Fe 3 o 4 Nanoparticles were dispersed in 50mL of ammonia water-ethanol mixed solution (10:1), stirred by electric motor at 600r / min for 10-15 minutes to disperse evenly; added TEOS drop by drop, continued to stir at 600r / min for 12 minutes, then transferred to In a beaker; place it in a 100Oe magnetic field for 10s, then keep it standing still for 15min, collect the precipitate, wash it repeatedly with alcohol and water for 3 times, and dry it in a vacuum oven at 60°C for 12h;

[0100] Ⅱ. Configuration solution: 3.0~5.0g of basic components of PAM precursor solution, 2.8mg of curing agent (N, N'-methylenebisacrylamide (MBAA)), 132mg of photoinitiator 2-hydroxy-2-methyl -1-Acetone (HMPP) is dispersed in 10mL water and mixed uniformly to obtain an aq...

Embodiment 2

[0106] The steps are the same as in Example 1, except that the magnetic field strength in step I needs to be changed to 200Oe, and the holding time is changed to 5s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com