Photoelectric film position adjusting device

A technology for adjusting devices and photoelectric thin films, applied in optics, nonlinear optics, instruments, etc., can solve the problems of slow manpower adjustment, no stable customer resources, insufficient capital scale, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

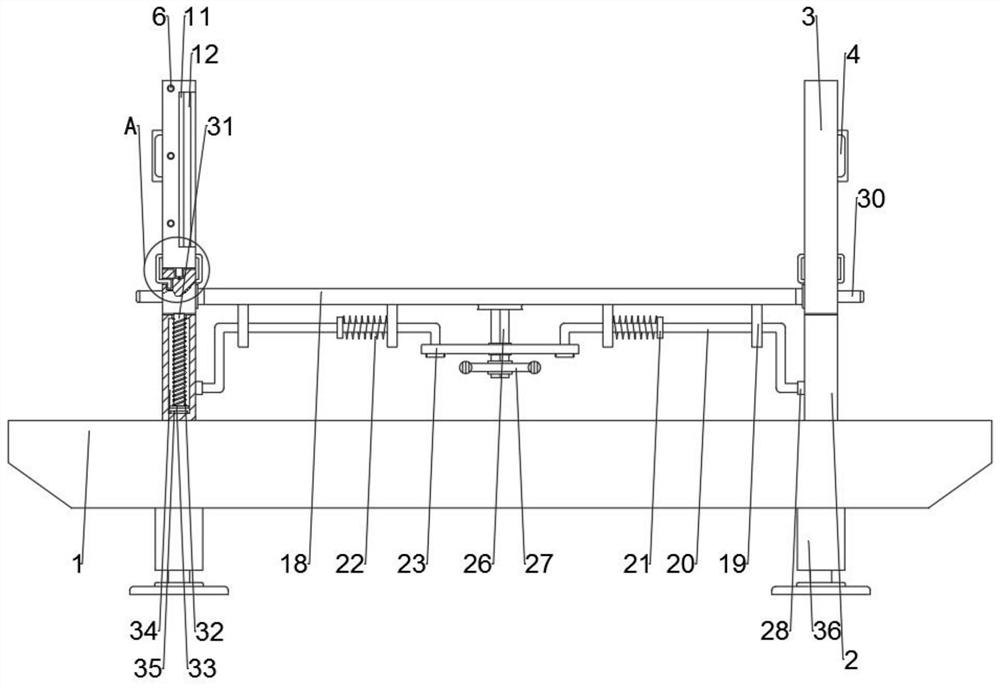

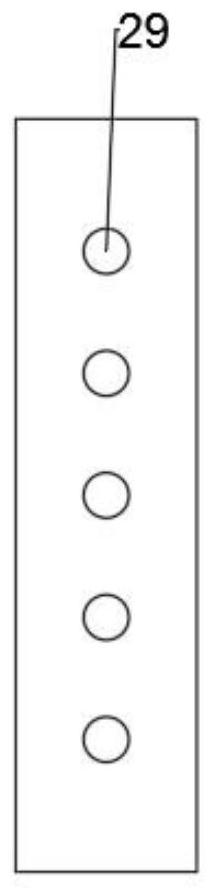

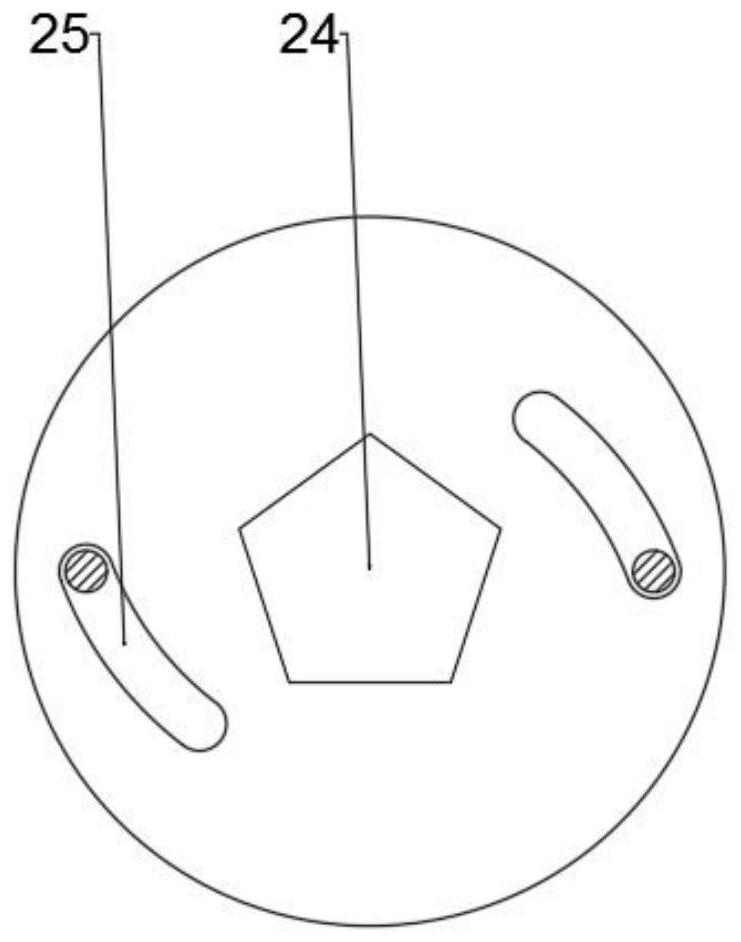

[0040] see Figure 1-5 , a photoelectric film position adjustment device, comprising a base 1 and bolts 10, a support plate 2 is fixed on the base 1, the support plate 2 is slidably connected to a connecting block 37, the connecting block 37 is slidably connected to a moving plate 3, and the connecting block 37 is fixed Connecting plate 5 is arranged, and moving plate 3 is corresponding with connecting plate 5 positions, and is provided with through hole 6 on moving plate 3, and is provided with through hole 6 on connecting plate 5, and the through hole 6 on moving plate 3 and connecting plate 5 offers The position is on the same horizontal line, the side walls of the moving plate 3 and the connecting plate 5 are provided with a fixed block 7, and a connecting rod 8 runs through between the fixed blocks 7, and the connecting rod 8 runs through the moving plate 3 and the connecting plate 5 through the through hole 6, and the moving plate 3 and the side close to the connection p...

Embodiment 2

[0042] see figure 1 and Figure 4 , the side wall of the connection block 37 is provided with handles 30, the handles 30 are evenly and symmetrically distributed on the side walls of the symmetrical connection block 37, and the handles 30 are used to lift the connection block 37 and move in the vertical direction so as to change the clamping photoelectric The height of the film is convenient for the staff to carry out the lamination operation. The side wall of the moving plate 3 is provided with grippers 4. The grippers 4 are evenly and symmetrically distributed on the side walls of the symmetrical moving plate 3. The grippers 4 are convenient for the moving plate 3 and the connecting plate 5. The auxiliary effect is played when the bolts 10 are close to each other.

Embodiment 3

[0044] see figure 1 and Figure 4 , the connecting rod 8 runs through the moving plate 3 and the connecting plate 5, the connecting rod 8 is covered with a spring 9, the spring 9 can make the moving plate 3 and the connecting plate 5 move closer to each other more stable, and also play a buffering effect To prevent excessive clamping force from damaging the photoelectric film, a gasket 12 is provided in the clamping groove 11. The gasket 12 has a good anti-skid effect and prevents the photoelectric film from sliding and changing its position after being clamped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com