Noodle forming equipment

A molding equipment and noodle technology, applied in dough molding and cutting equipment, dough extruder, etc., can solve time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

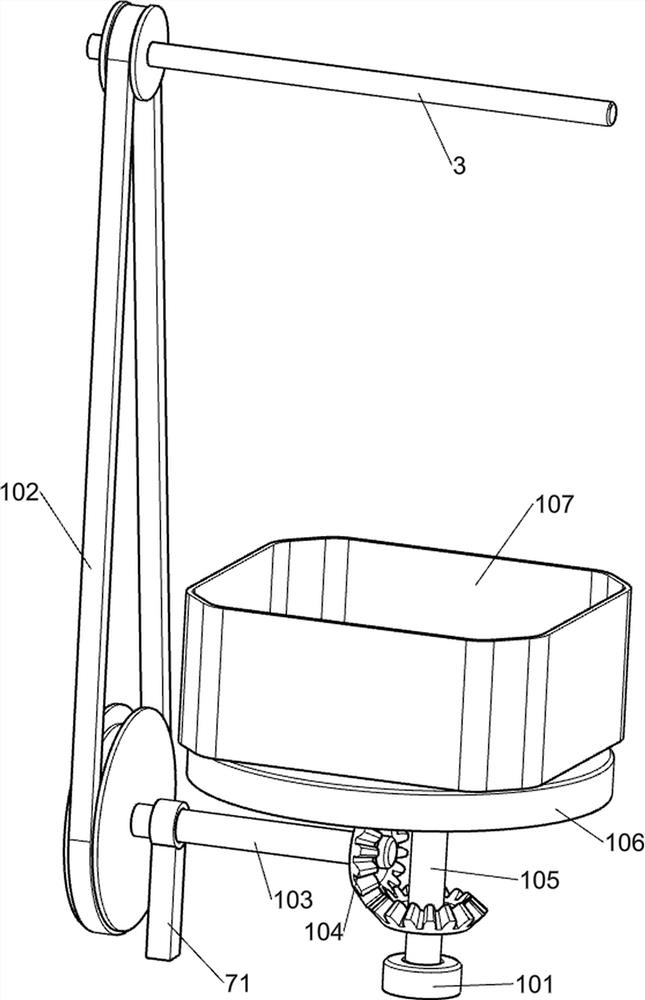

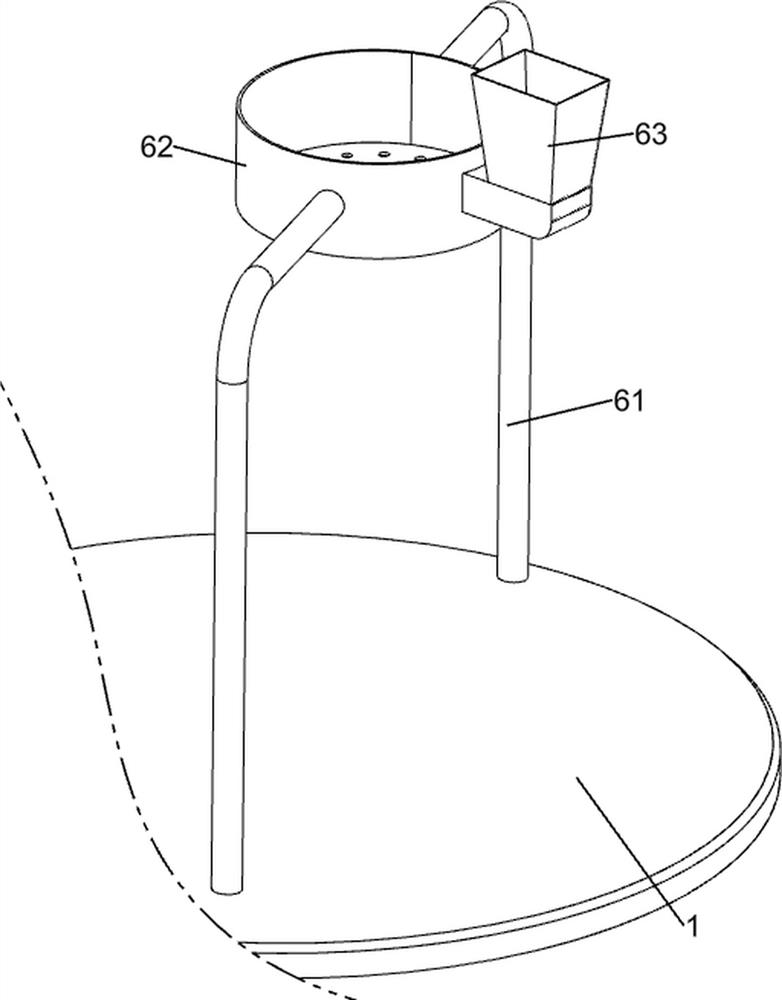

[0073] A noodle forming equipment such as Figure 1-4 As shown, it includes a base plate 1, a first support frame 2, a motor 3, a second support frame 4, a pressing mechanism 5 and a material holding mechanism 6, the right side of the base plate 1 is provided with a first support frame 2, and the first support frame 2 The top is provided with a motor 3, the top of the first support frame 2 is provided with a second support frame 4, the second support frame 4 is rotationally connected with the output shaft of the motor 3, the bottom plate 1 is provided with a pressing mechanism 5, and the bottom plate 1 is provided with a holding Material mechanism6.

[0074] When people need to shape noodles, they can use this equipment. First, put the noodle-loading tool under the filling mechanism 6, then put the dough into the 6 parts of the filling mechanism, and squeeze the dough manually to make the dough fall into the filling mechanism. In another part of the mechanism 6, start the mot...

Embodiment 2

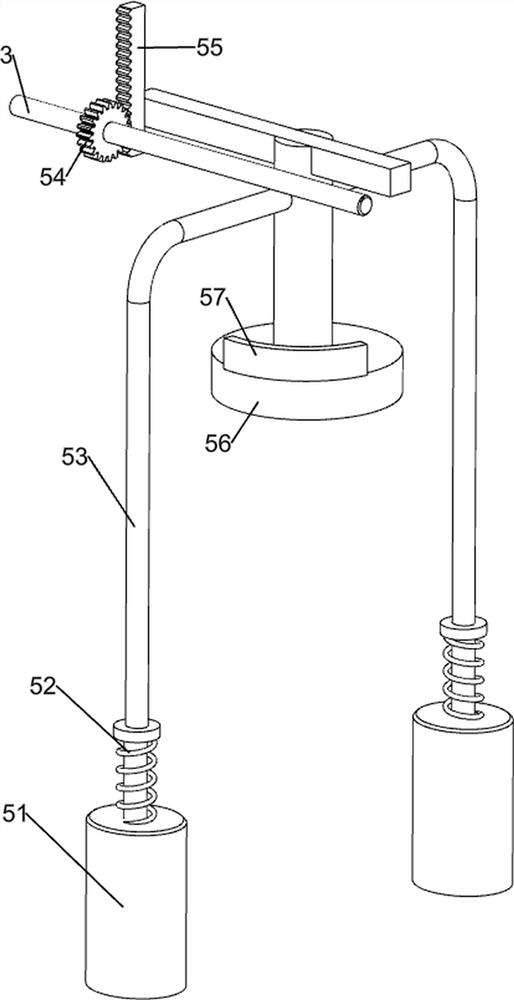

[0080] On the basis of Example 1, such as Figure 5-8 As shown, a cutting mechanism 7 is also included, and the cutting mechanism 7 includes a fifth support frame 71, a sixth support frame 72, a first rotating shaft 73, a second gear 74, a second rack 75, a second spring wire 76, a blade 77, cable pulley 78, second rotating shaft 79, stay cord 710, third gear 711, third rack 712, second support block 713 and seventh support frame 714, base plate 1 left side is provided with seventh support frame 714, The seventh supporting frame 714 middle part is rotatably provided with the first rotating shaft 73, and the first rotating shaft 73 is provided with the second gear 74, and the seventh supporting frame 714 top sliding type is provided with the second rack 75, and the second rack 75 is connected with the second rack. The two gears 74 are engaged, the second spring wire 76 is provided between the second rack 75 and the seventh support frame 714, the sixth support frame 72 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com