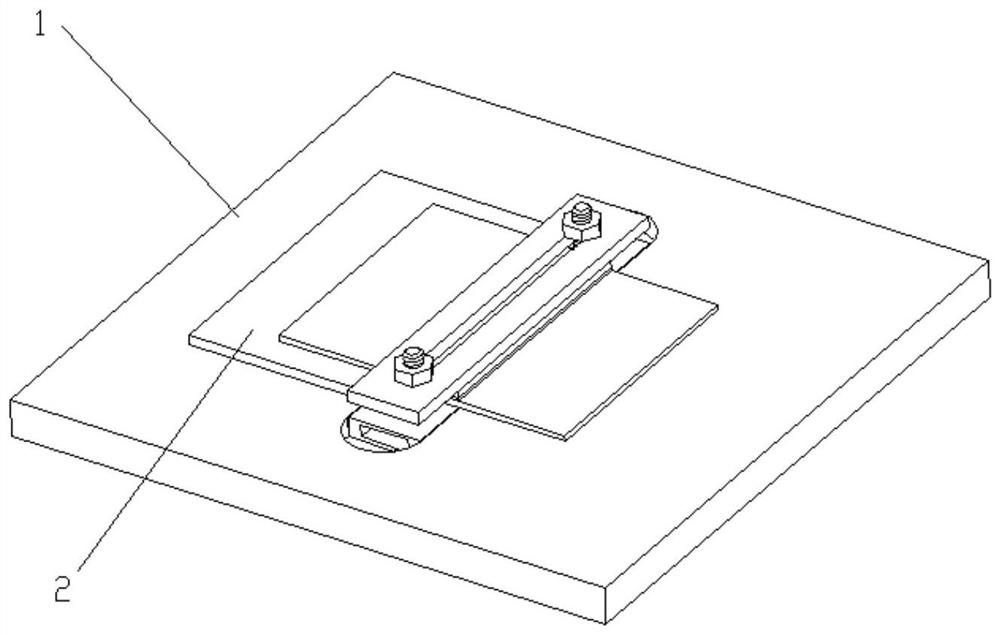

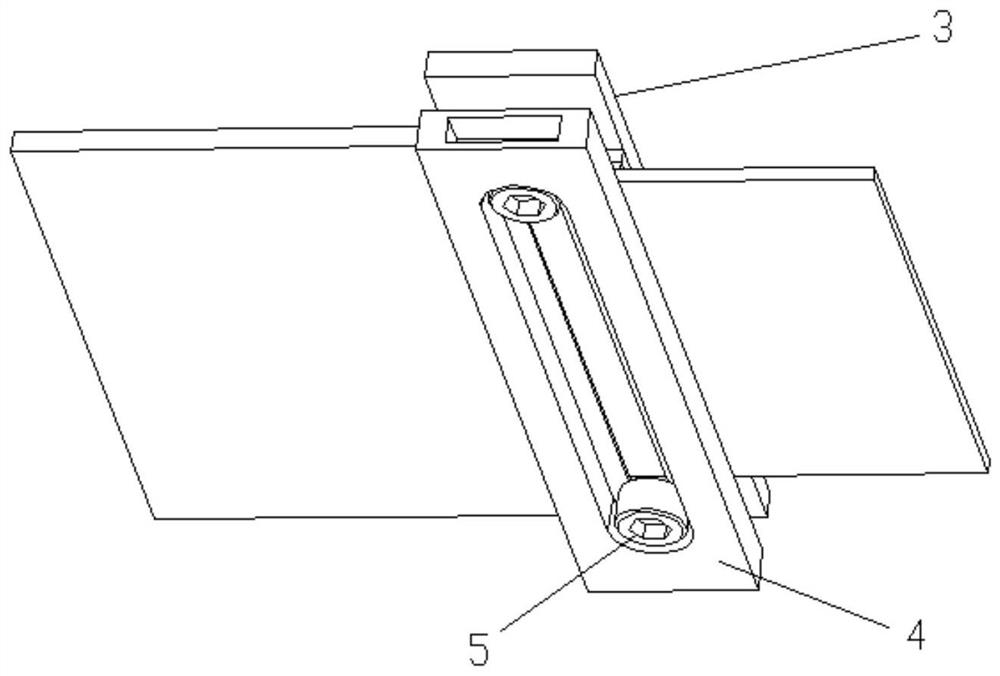

A method of film thickness control

A technology of thickness control and adhesive film, which is applied in the direction of material gluing, device for coating liquid on the surface, connecting components, etc., can solve the problems such as the thickness control of the adhesive film and the uniformity of the adhesive film thickness can not be better guaranteed, to achieve Solve uneven bonding, improve production efficiency, and facilitate manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

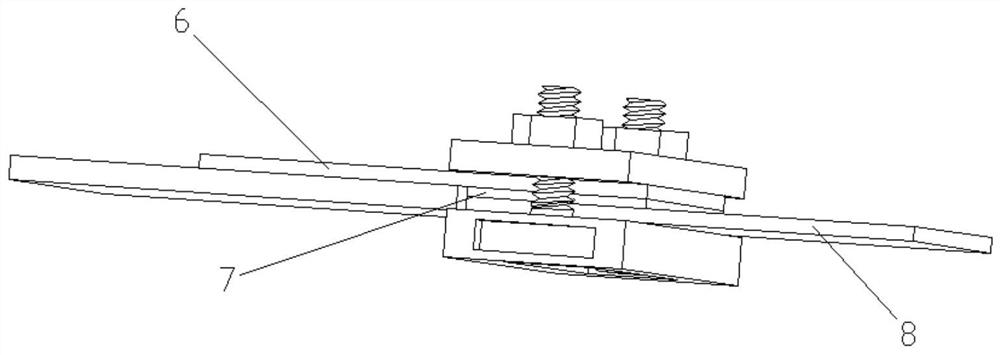

[0065] The thickness difference die plate used is 0.1mm higher than the lower connecting plate, and the upper connecting plate and the lower connecting plate are connected by the adhesive film by using the film thickness control device in the present invention, and the adhesive curing and forming are completed in the autoclave. , the actual film thickness is 108μm through measurement.

Embodiment 2

[0067] The thickness difference die plate used is 0.2mm higher than the lower connecting plate, and the upper connecting plate and the lower connecting plate are connected by the adhesive film by using the film thickness control device in the present invention, and the bonding and curing molding is completed in the autoclave. , the actual film thickness is 209μm through measurement.

Embodiment 3

[0069] The thickness difference die plate used is 0.5mm higher than the lower connecting plate, and the upper connecting plate and the lower connecting plate are connected by the adhesive film by using the film thickness control device in the present invention, and the bonding and curing molding is completed in the autoclave. , the actual film thickness is 522μm through measurement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com