Patents

Literature

50results about How to "Control film thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

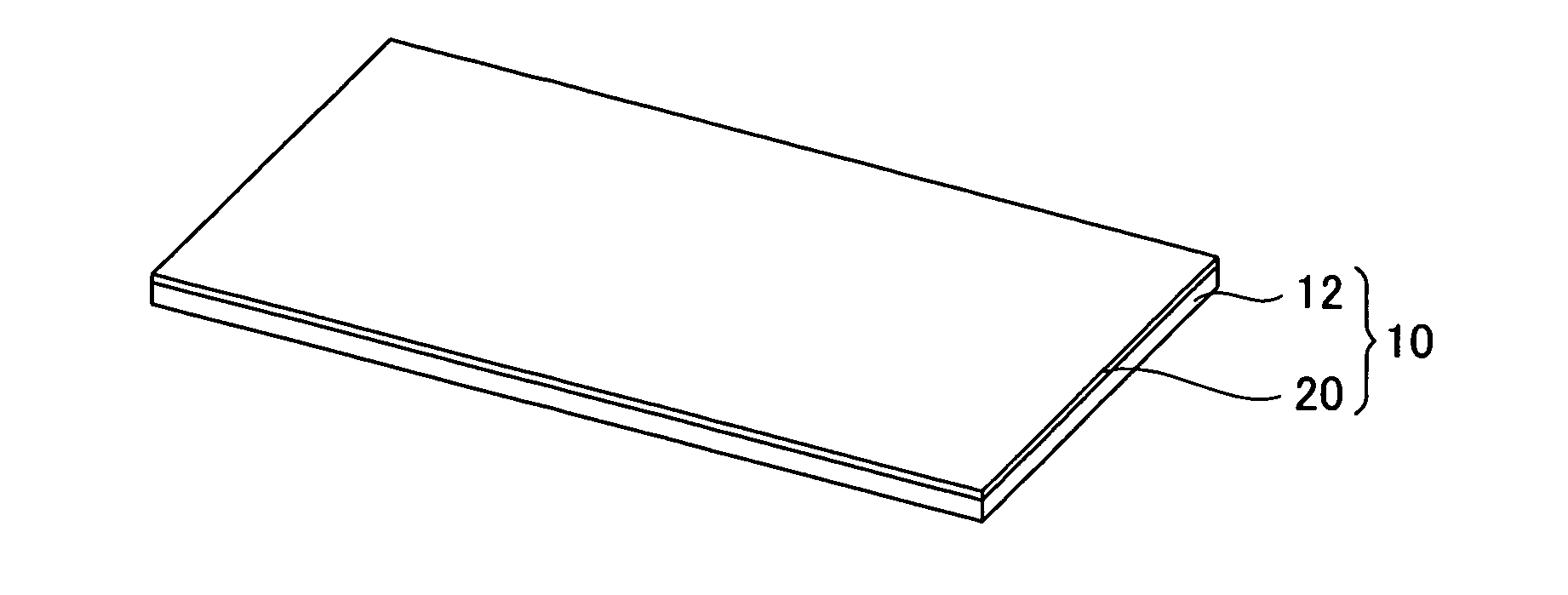

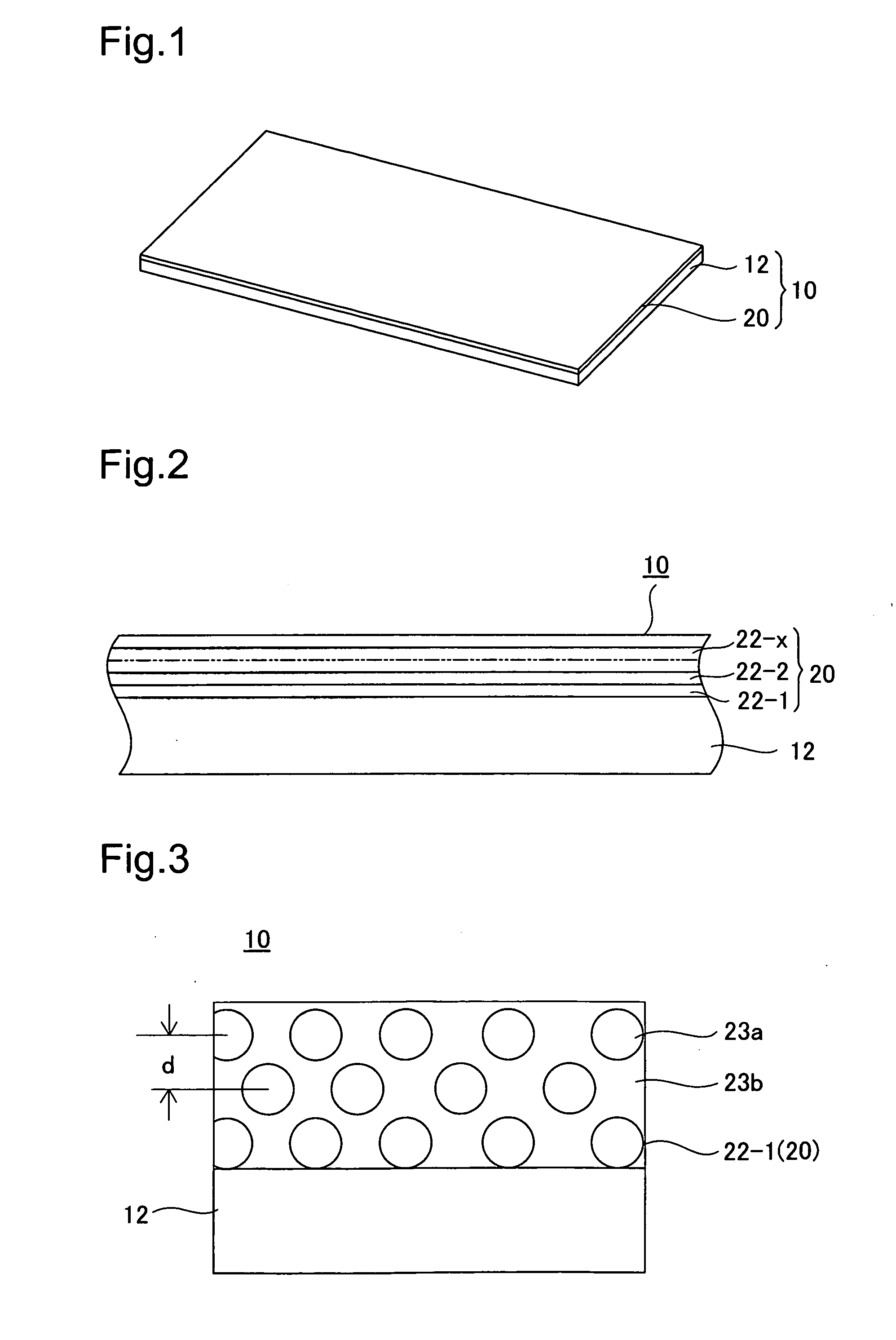

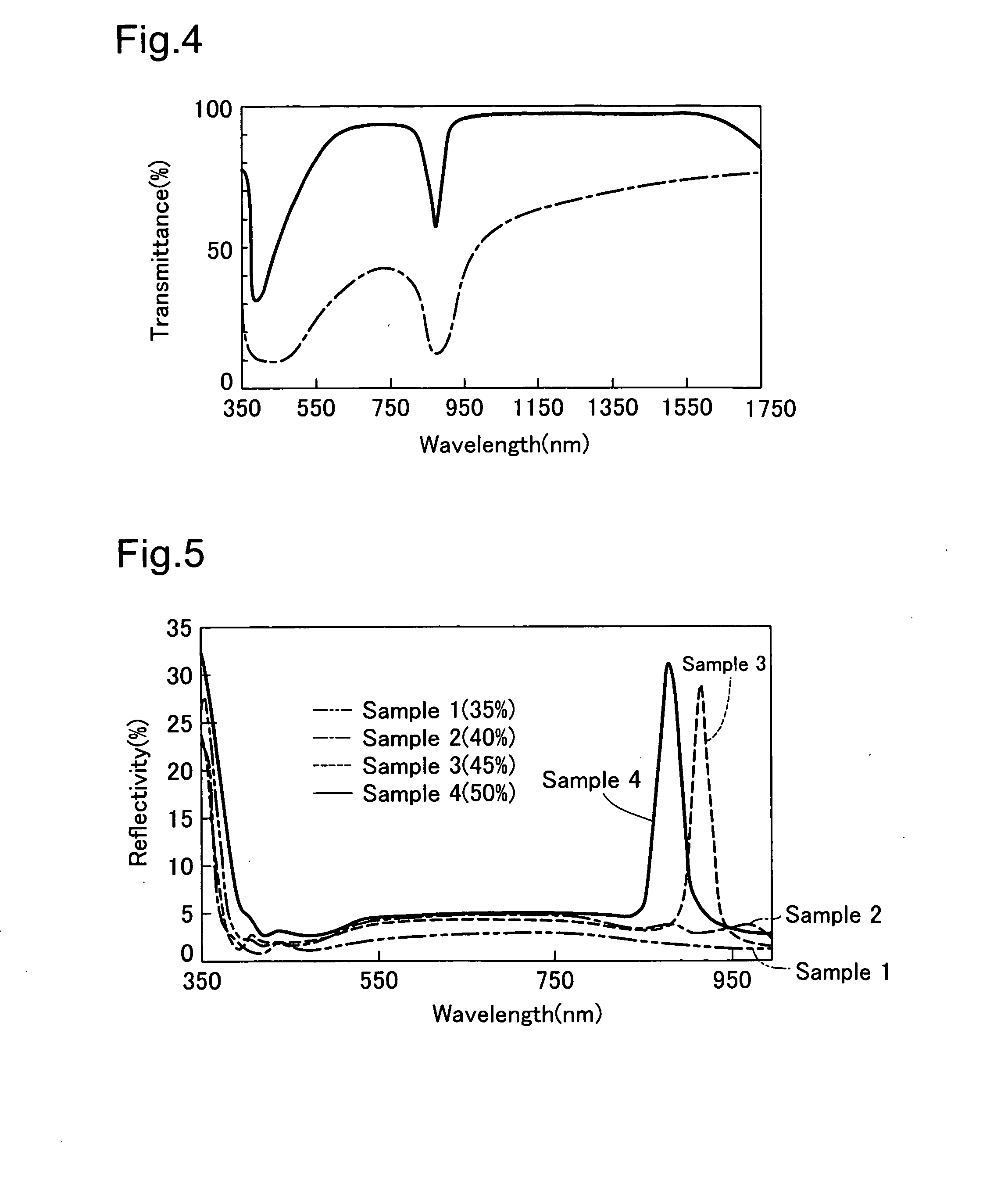

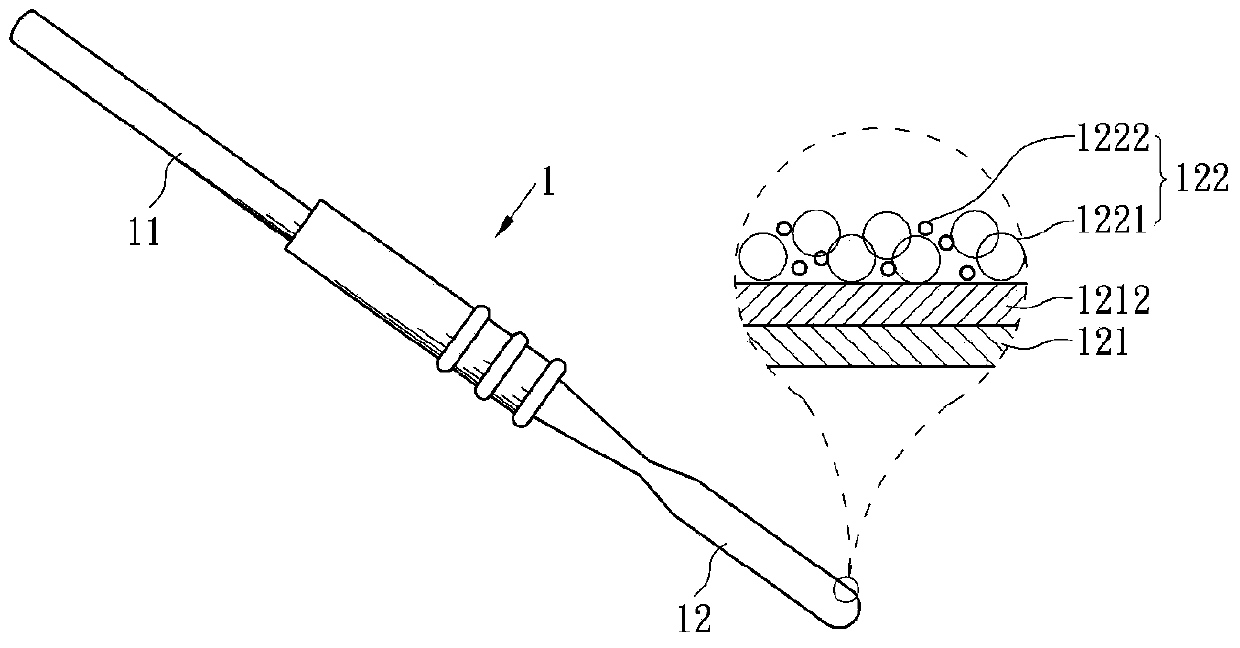

Infrared reflective member, and infrared reflective device and method of making same

InactiveUS20090015908A1Increase reflectivityControl film thicknessPrismsMirrorsFilling materialsColloidal particle

The infrared reflective device includes infrared reflective members which reflect infrared rays. The infrared reflective members include colloidal particles arranged at regular spacing, and a filler material intervening in the spaces between the colloidal particles. The difference between the refractive index of the colloidal particles and the refractive index of the filler material is set so as to be 0.05 or less in the visible light region and 0.1 or above in the infrared region, whereby visible light is transmitted while infrared rays are reflected.

Owner:TOYODA GOSEI CO LTD

Preparation method of NiO porous membrane

ActiveCN102251267AMild preparation conditionsReduce manufacturing costAnodisationMuffle furnaceElectrolyte

The invention discloses a preparation method of NiO porous membrane. According to the invention, first, an Ni substrate is pretreated; the pretreated Ni substrate is adopted as an anode, a Pt sheet is adopted as a cathode, a nitric acid solution is adopted as an electrolyte, and an anodic oxidation treatment is carried out for 5min to 30min with an applied voltage of 5V to 25V while the electrolyte is stirred; the Ni substrate processed from the anodic oxidation treatment is washed with deionized water, and is naturally dried in air, such that an Ni substrate with an amorphous NiO porous membrane is obtained; the Ni substrate with the amorphous NiO porous membrane is baked in a muffle furnace, such that an Ni-based crystalline cubic phase NiO porous membrane is obtained. According to the invention, no obvious boundary is between the NiO porous membrane and the substrate material which is the Ni substrate; and bonding strength between the two is high. NiO porous membranes produced withother methods have problems of deformation, efflorescence and peeling during long-term use. With the method provided by the invention, the problems are solved, and the cycling stability of the product is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Waterborne polyurethane film and preparation technology thereof

ActiveCN101921536AControl melt fluidityControl film thicknessPolyurea/polyurethane coatingsChemistryEmulsion

The invention relates to a waterborne polyurethane film and a preparation technology thereof. The preparation technology comprises the following steps: (1) mixing waterborne polyurethane emulsion, a thickener and a pH regulator to prepare a waterborne polyurethane painting, wherein the weight of the thickener accounts for 0.5%-3% of that of the waterborne polyurethane emulsion and the weight of the pH regulator accounts for 0.05%-0.5% of that of the waterborne polyurethane emulsion; (2) placing the waterborne polyurethane painting obtained in step (1) on a base material; (3) dragging the base material to cause the waterborne polyurethane painting to pass through a knife-edge gap, thereby ensuring the film thickness to be 10 mu m-20 mu m; and (4) carrying out drying and rolling on the waterborne polyurethane film obtained in step (3). In the process of the technology of the invention, organic solvent does not volatilize or a little amount of the organic solvent volatilizes and control equipment with complicated fusion, extrusion or calendar is in no need, thereby having the advantages of stability and reliability.

Owner:武汉华卫科技有限公司

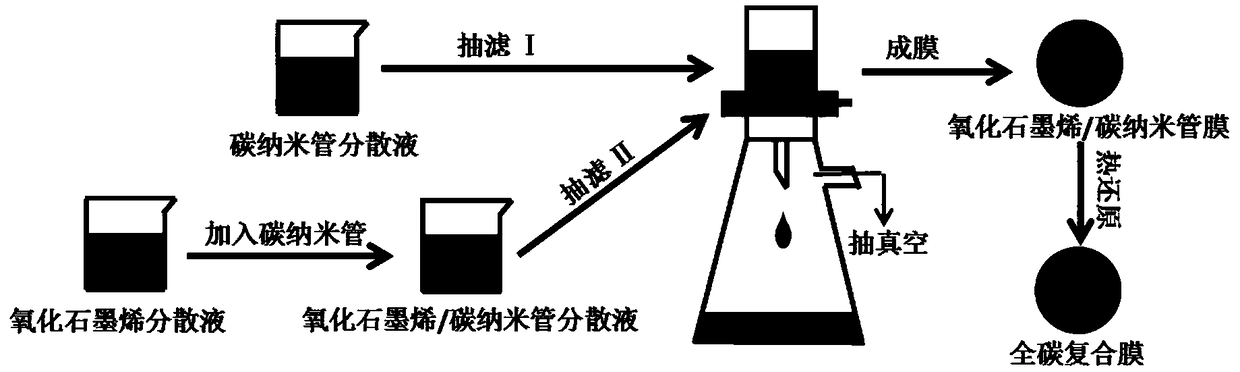

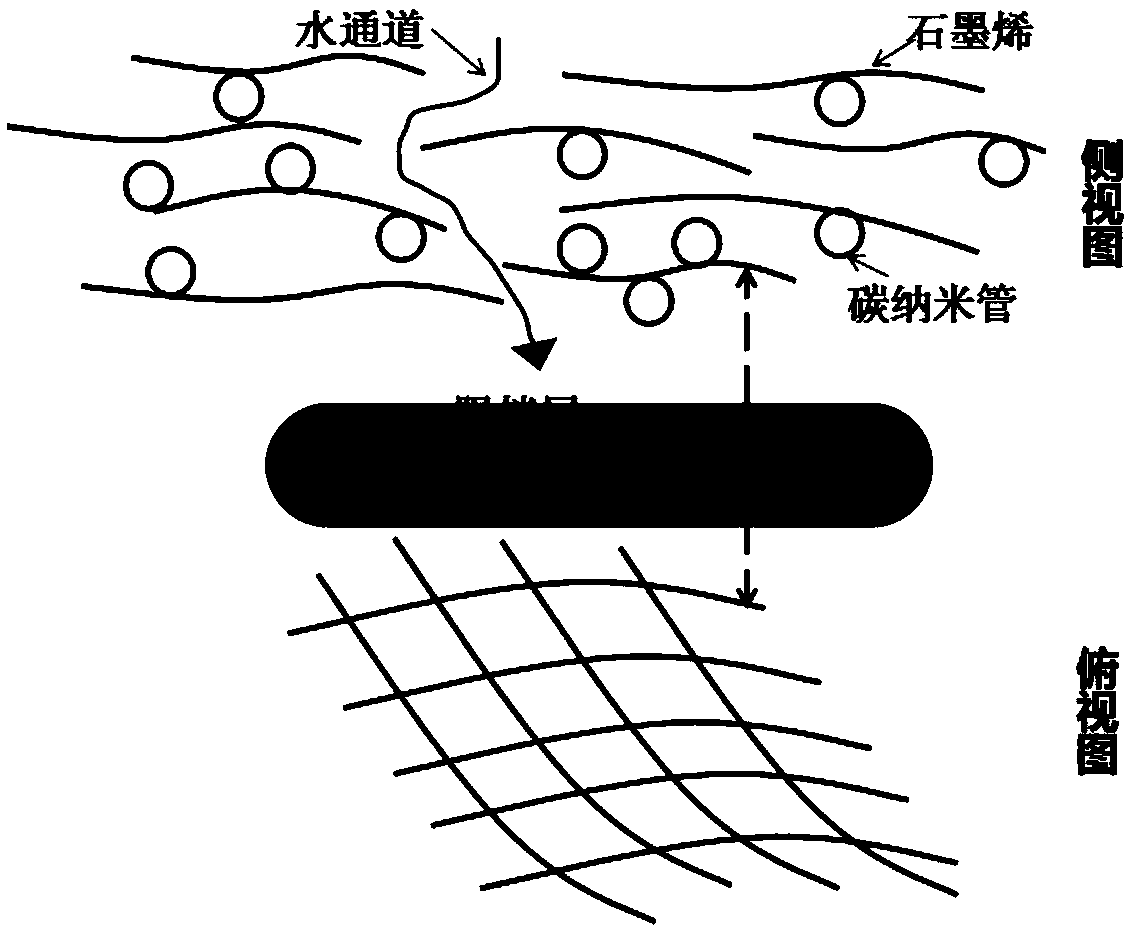

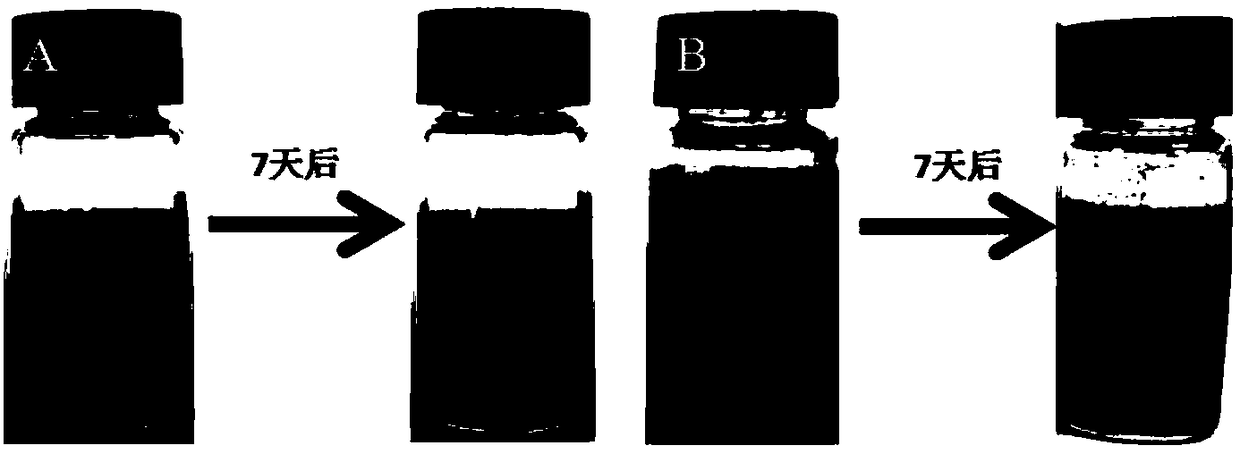

Preparation method of all-carbon composite film and product of all-carbon composite film

InactiveCN108722198ASimple stepsReduce the impactSemi-permeable membranesWater contaminantsCarbon nanotubeBinding force

The invention belongs to the field of preparation of composite films and discloses a preparation method of an all-carbon composite film. The method comprises the following steps: firstly, taking graphite as a raw material, and controllably synthesizing graphene oxide by adopting an improved Hummers method; effectively dispersing carbon nanotubes in a water solution through graphene oxide containing abundant oxygen functional groups, so as to form a stable graphene oxide / carbon nanotube dispersion solution; then forming a film through a method for sequentially filtering a carbon nanotube dispersion solution and the graphene oxide / carbon nanotube dispersion solution in one step in vacuum; finally, carrying out heat treatment in a reduction atmosphere to obtain the all-carbon composite film.The invention further discloses a product obtained by the preparation method and application of the product. According to the preparation method provided by the invention, the controllability of preparation technology parameters is strong, the operation is simple and feasible and the structure of the obtained all-carbon composite film is complete; the binding force between a film base layer and astopping layer is strong; the all-carbon composite film has a very good separation effect on dyestuff and can be used for efficiently intercepting the dyestuff in water; the all-carbon composite filmhas a very good application prospect in the aspect of separating the dyestuff.

Owner:HUAZHONG UNIV OF SCI & TECH

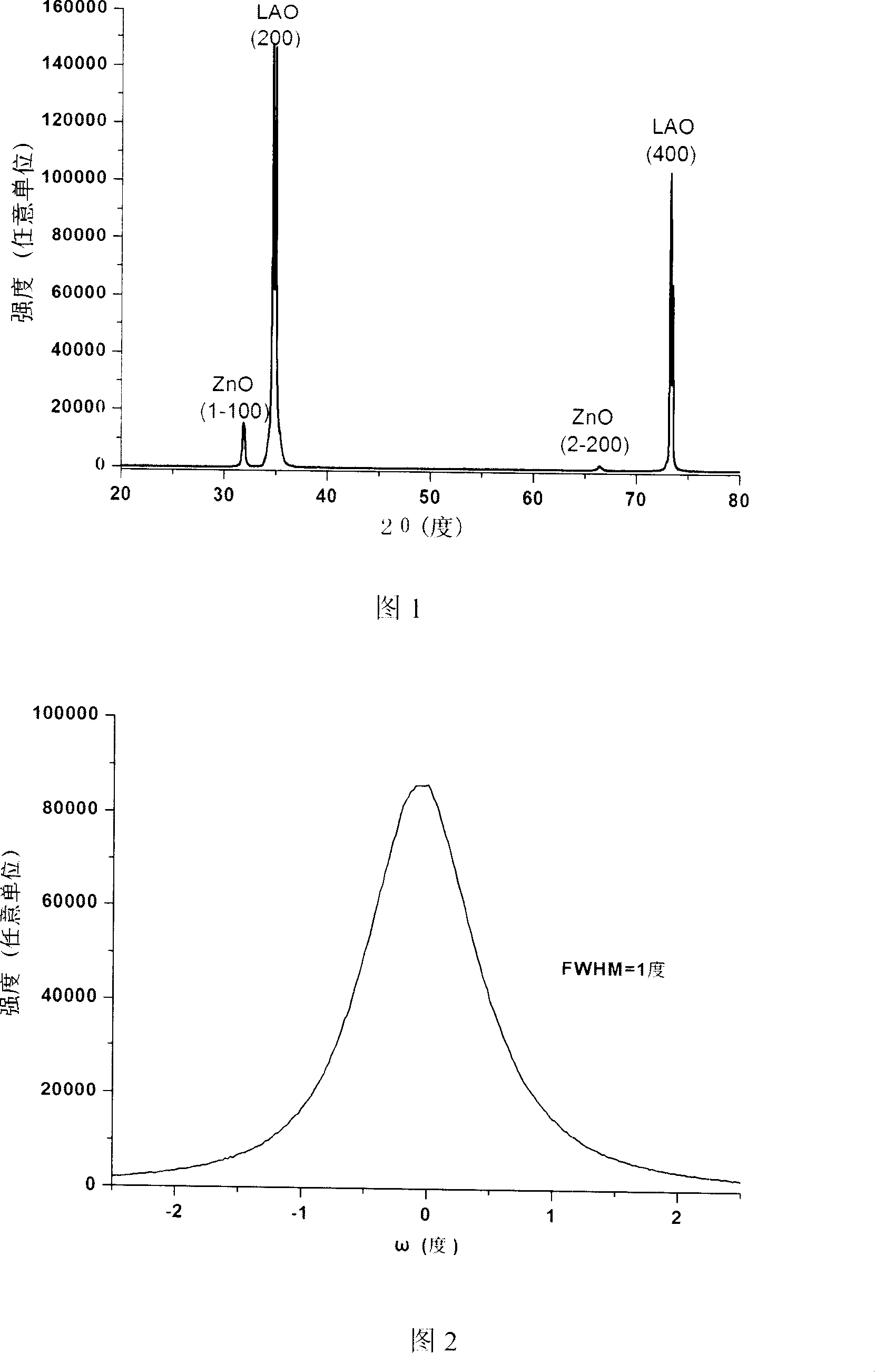

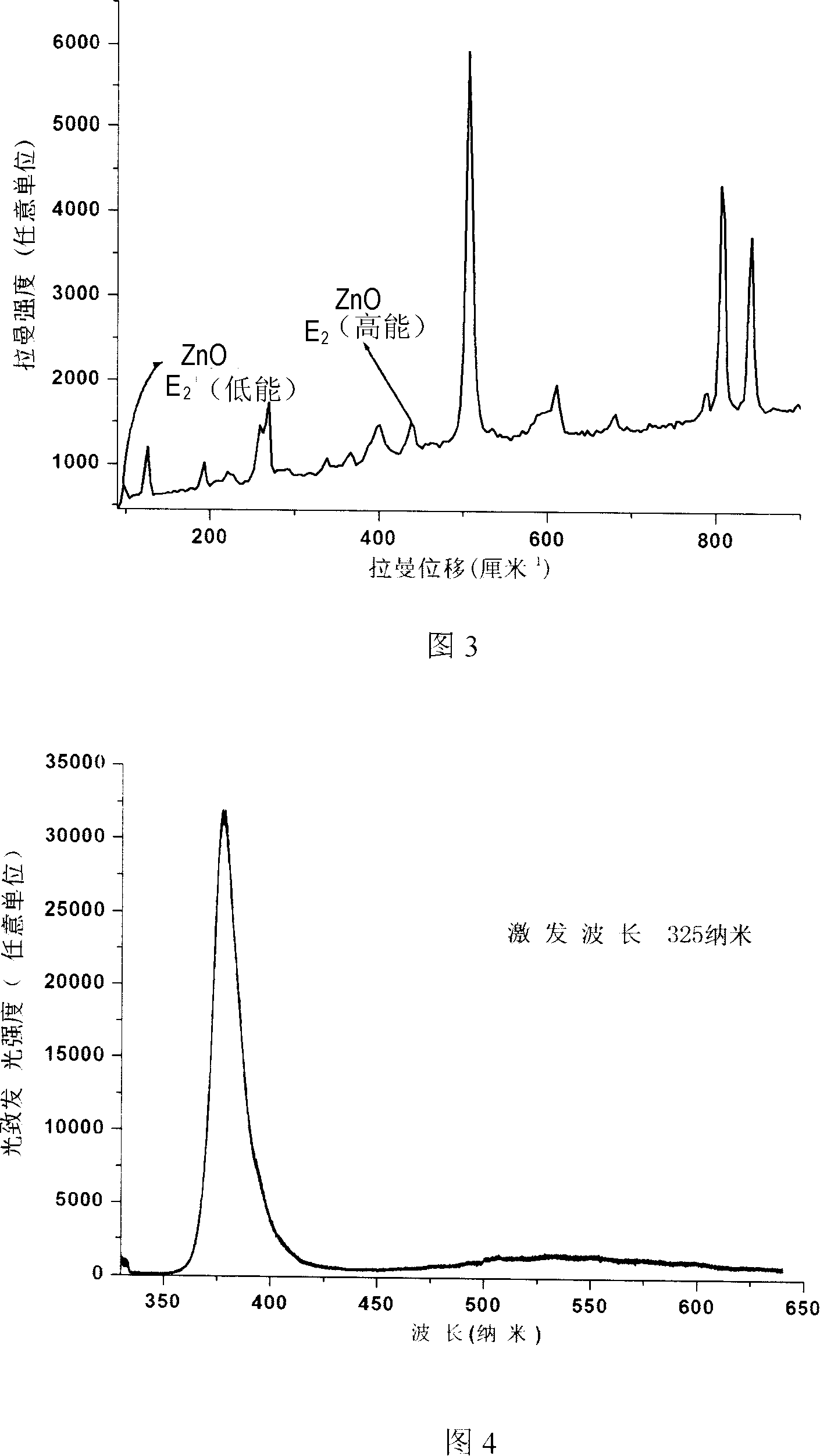

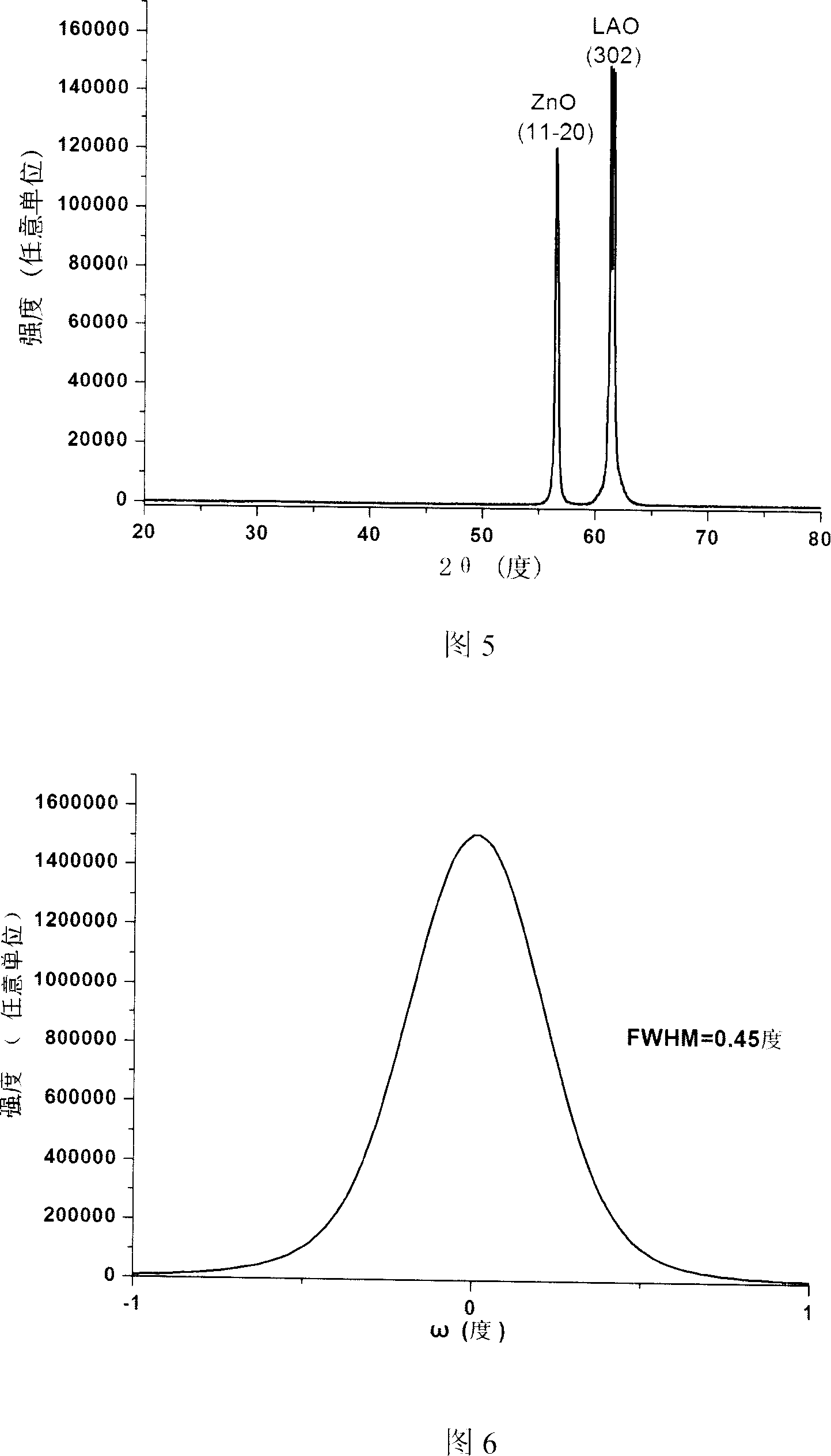

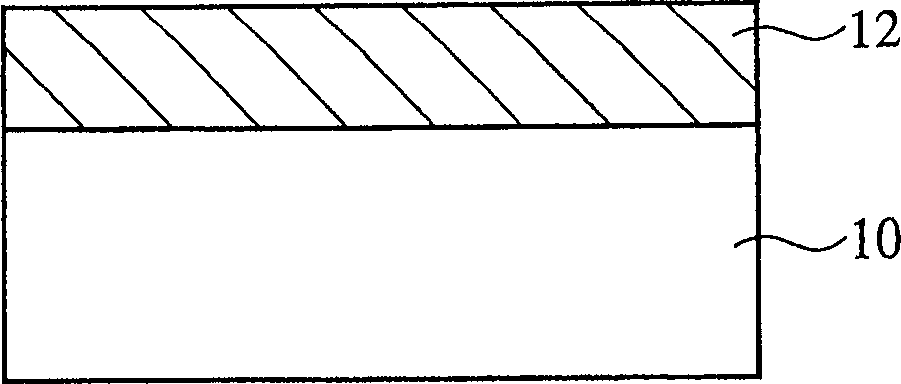

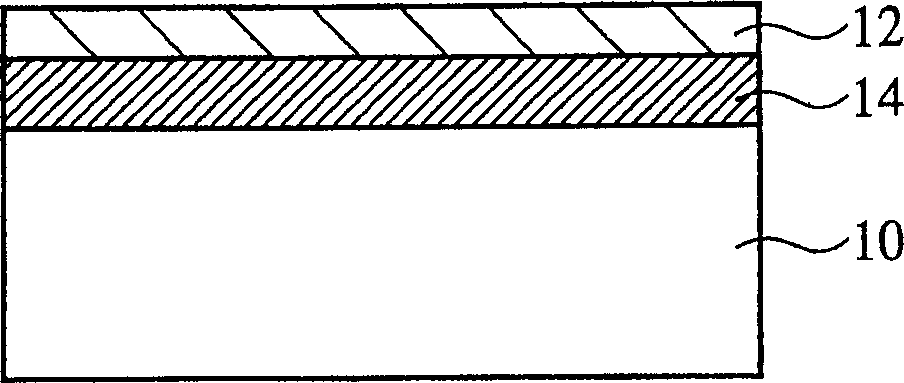

Method for developing m-face or a-face ZnO film by metal organic chemical vapour deposition

InactiveCN101082124AControl film thicknessEasy maintenanceChemical vapor deposition coatingGas phaseSingle crystal

The present invention is metal organic chemical vapor deposition process of growing ZnO film in m plane or a plane, and features that in a low pressure metal organic chemical vapor deposition system, gamma-LiAlO2 monocrystal substrate of (100) plane or (302) plane is set on the bearing stage for ZnO film to grow on with diethyl zinc as the zinc source, high purity oxygen as the oxygen source and high purity argon as the saturated zinc vapor carrier and diluting gas. The ZnO film growing conditions include diethyl zinc bubbler pressure of 760 torr, zinc source flow rate of 15-25 sccm, O2 flow rate of 100-150 sccm, Ar flow rate of 80-120 sccm, O / Zn molar ratio of 80-200, vacuum chamber pressure of 80-120 Pa, growth temperature of 400-750 deg.c and growth time of 20-60 min. The present invention can grow high quality non-polar ZnO film and possesses excellent industrial application value.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Semiconductor device and method for manufacturing same

InactiveCN1700478AInhibition formationAvoid formingSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorHeat treated

The method for fabricating a semiconductor device comprises the step of forming an Ni film 66 on a source / drain diffused layers 64 , the first thermal processing step of reacting a part of the Ni film 66 on the lower side and a part of the source / drain diffused layers 64 on the upper side with each other by thermal processing to form Ni2Si films 70 b on the source / drain diffused layers 64 , and the step of etching off the part of the Ni film 66 , which has not reacted, and the second thermal processing of reacting by thermal processing the Ni2Si films 70 b and parts of the source / drain diffused layers 64 on the upper side with each other.

Owner:FUJITSU LTD

Hydrophobicity conductive tool coated with chromium carbide base metal ceramic electroplated layer and method for manufacturing same

ActiveCN103726091AGood corrosion resistanceImprove electrical conductivity and corrosion resistanceElectrolytic inorganic material coatingChromium carbideLinear polarization

The present invention relates to a hydrophobicity conductive tool coated with a chromium carbide base metal ceramic electroplated layer and a method for manufacturing same. The hydrophobicity conductive tool is characterized in that the chromium carbide base metal ceramic electroplated layer is electroplated on teh surface of the tool, has an electrical conductivity that the specific resistance is less than 100 Ohms, a hydrophobicity that the water contact angle is greater than 94 degrees and a performance that a linear polarization corrosion current is less than 1*10-5 amperes, can be applied to the tool of high precision and rigidity, wear resistance, hydrophobicity and good electrical conductivity, such as medical scalpel, battery polar plate, joint, pin, etc. The present invention also provides a trivalent chromium electroplating method for manufacturing the hydrophobicity conductive tool.

Owner:张益诚

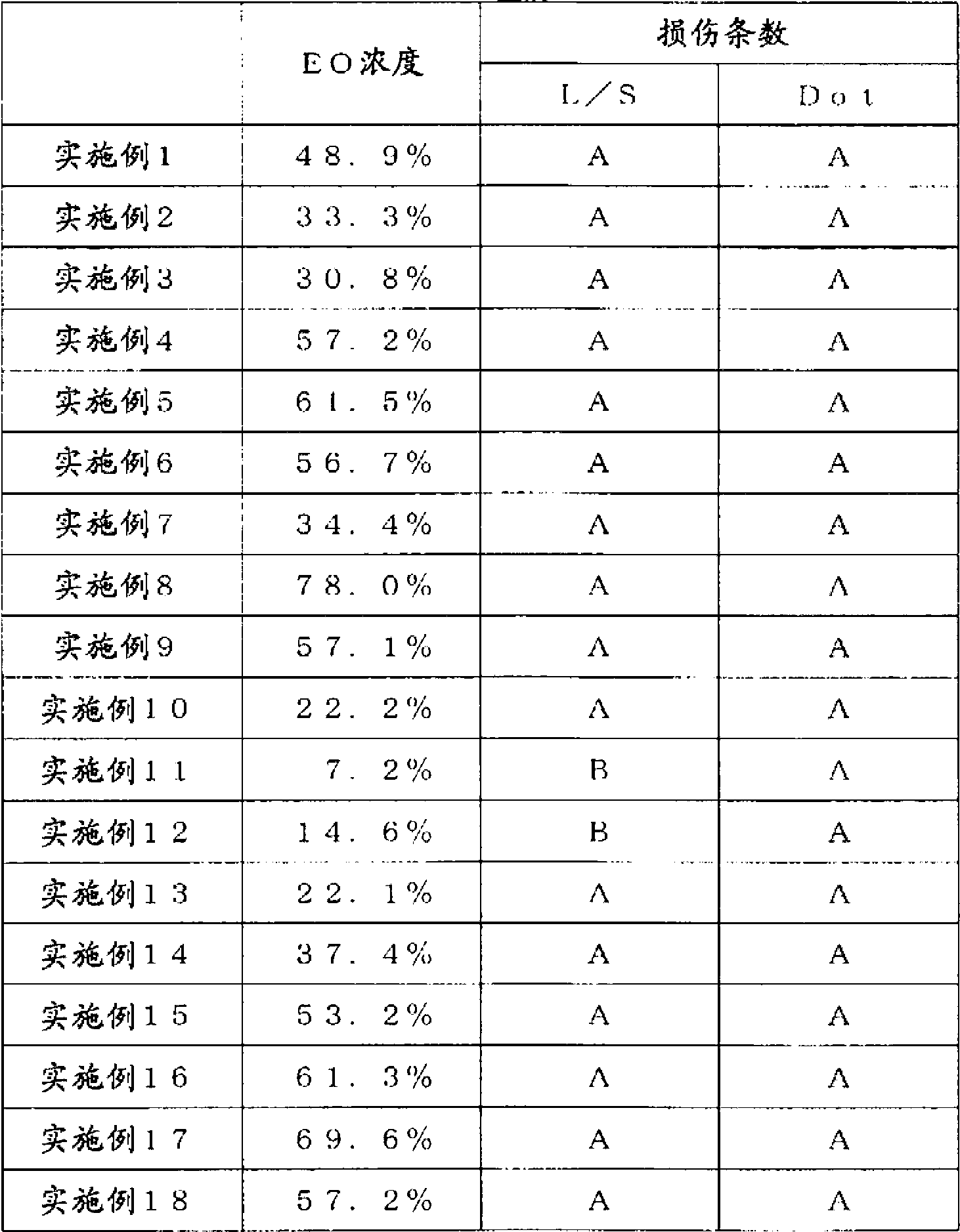

Highly abrasion-resistant imprint material

ActiveCN102939640AForming accuratelyEfficient formationNanoinformaticsPhotomechanical apparatusOxide

Provided is a highly abrasion-resistant imprint material. The imprint material comprises a compound that has C2-3 alkylene oxide units and at least two polymerizable groups as component (A) and a photopolymerization initiator as component (B). The polymerizable groups are at least one selected from the group consisting of acryloyloxy, acryloyl, methacryloyloxy, and methacryloyl groups. The imprint material can further comprise, in addition to component (A), a compound that has at least two polymerizable groups but does not have C2-3 alkylene oxide units as component (A').

Owner:NISSAN CHEM IND LTD

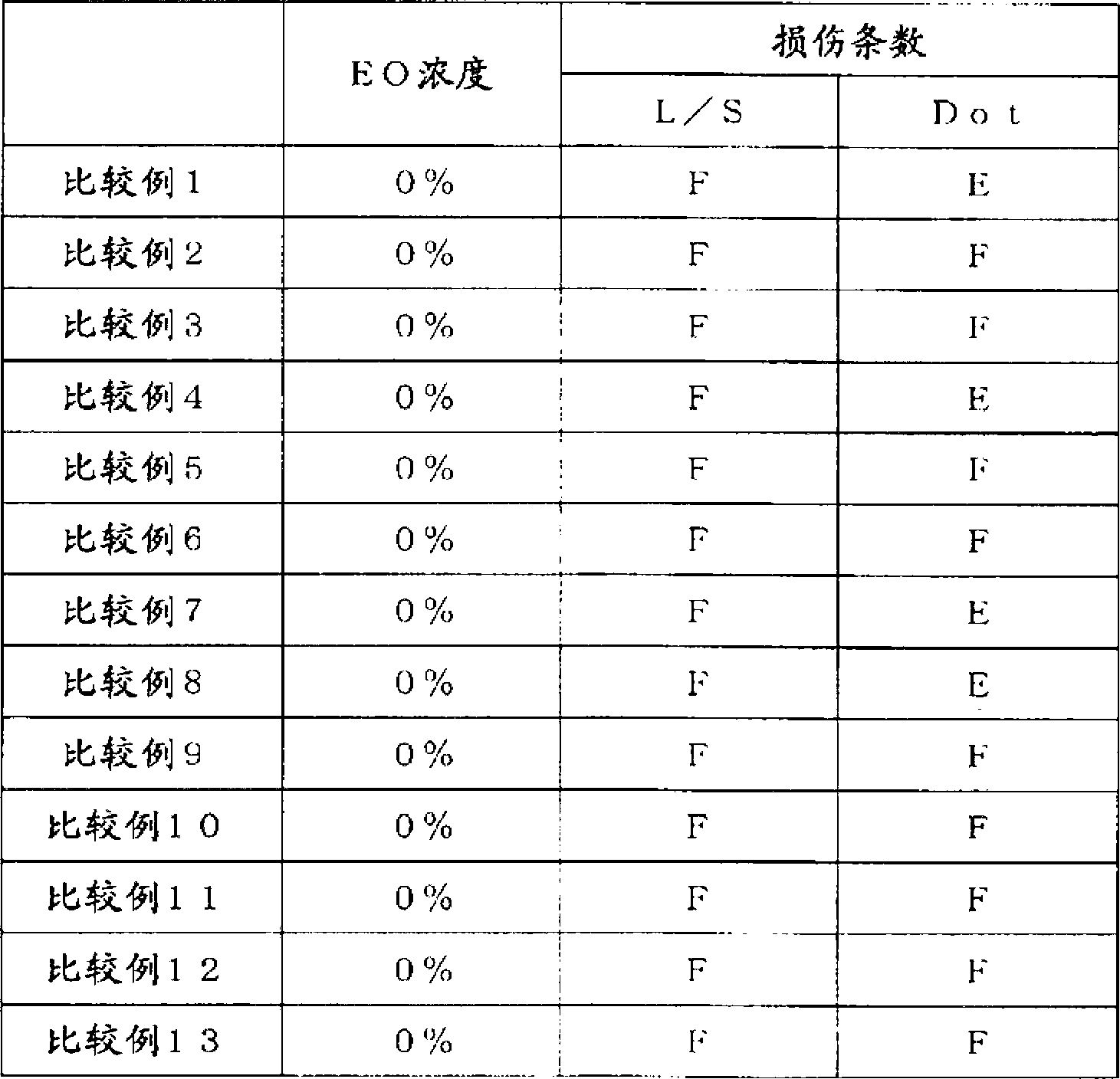

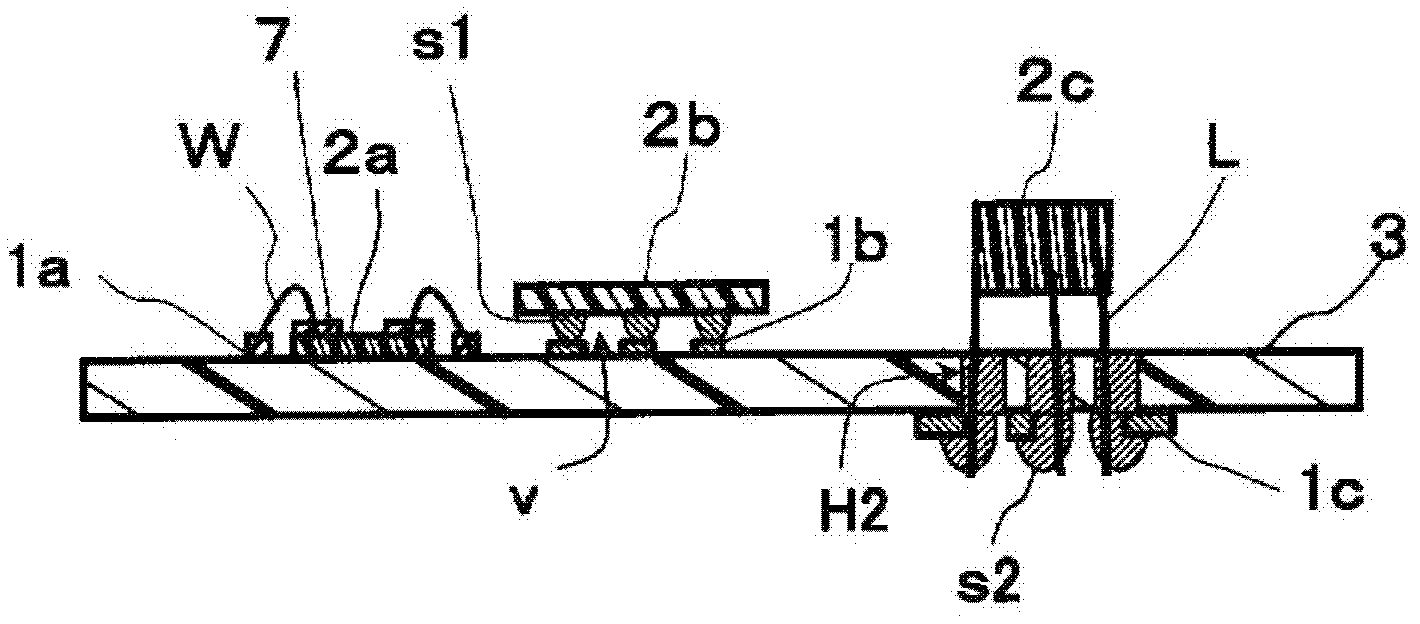

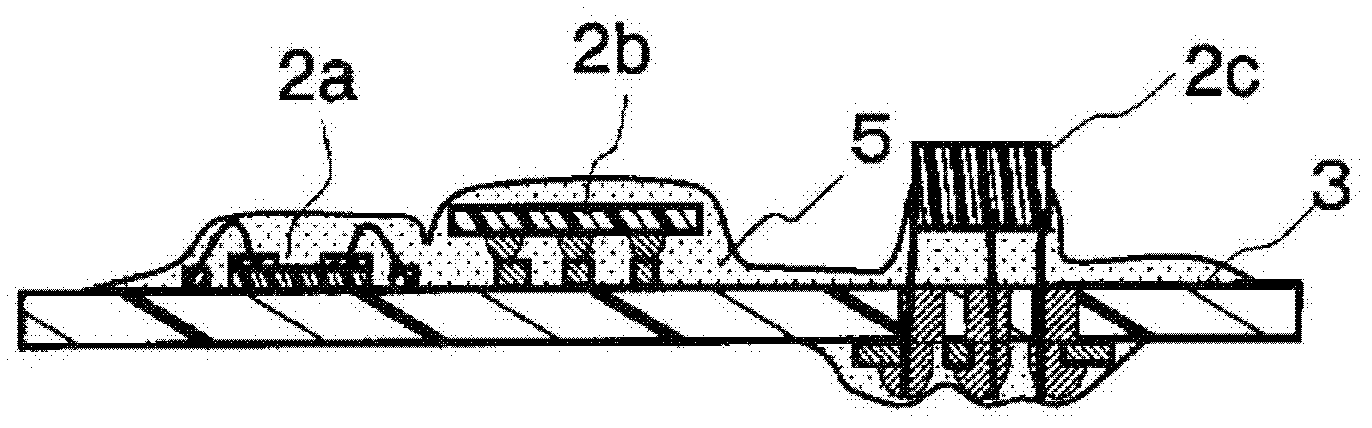

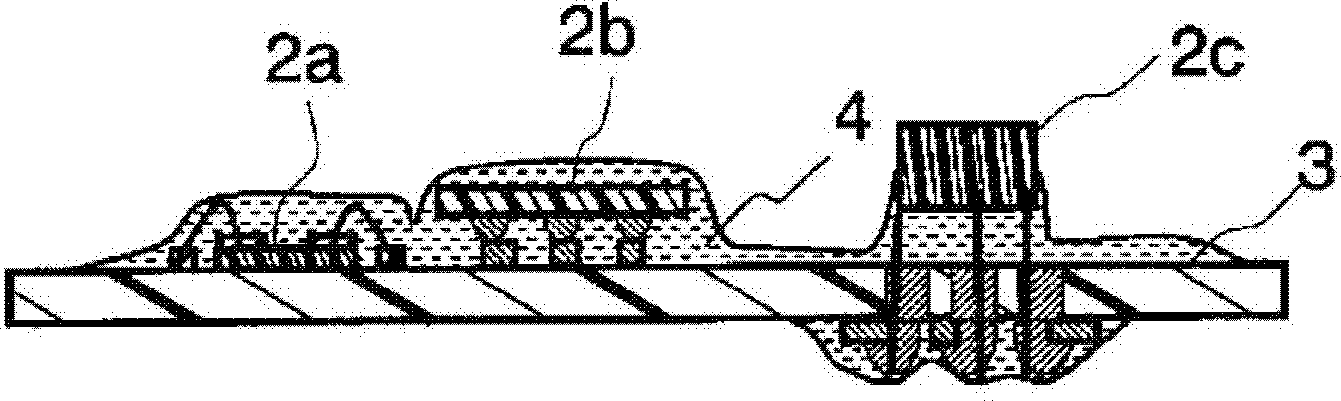

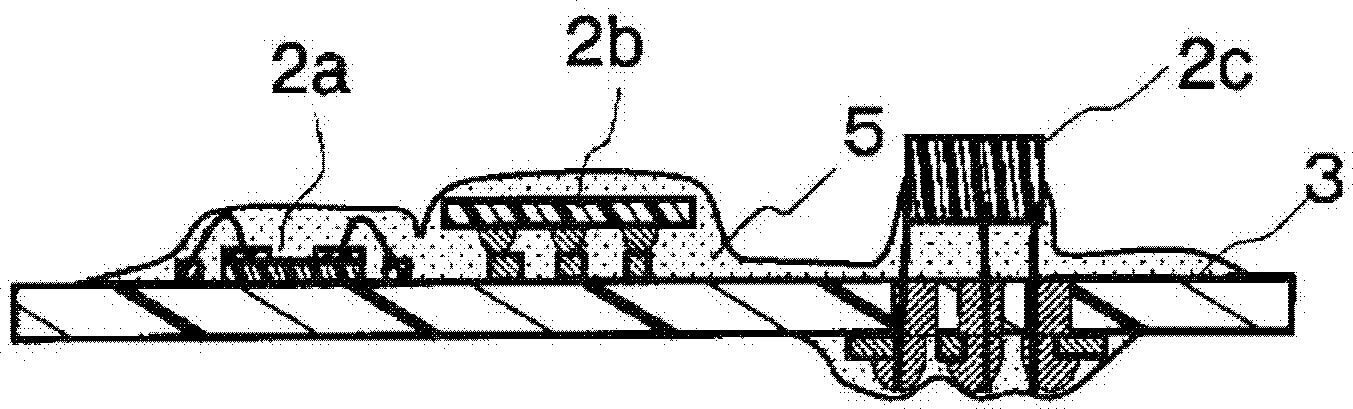

Method of producing electronic component mounting structure, and electronic component mounting structure

InactiveCN102460667AControl film thicknessPorous dielectricsSemiconductor/solid-state device detailsSolderingEngineering

Disclosed is a method of producing an electronic component mounting structure, provided with a mounting step of mounting an electronic component on a circuit board by soldering terminals connected to the electronic component to electrodes formed on a circuit board surface, a coating step of coating a liquid state curable resin composition so as to cover the soldered section on the surface of the circuit board surface formed by soldering, said liquid state curable resin composition including a curable resin and a foaming agent, a curing step of forming a cured resin by curing the liquid state curable resin composition at a temperature lower than the temperature at which the foaming agent foams, and a foaming step which causes a foaming agent to foam by heating at least a portion of the cured resin.

Owner:PANASONIC CORP

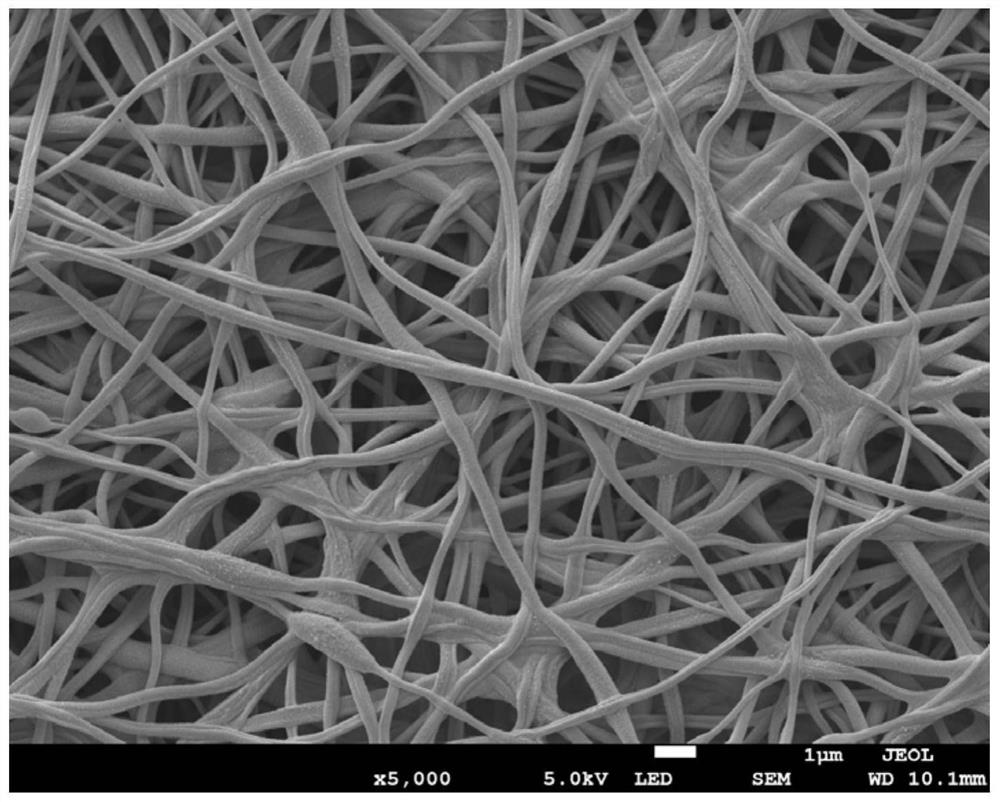

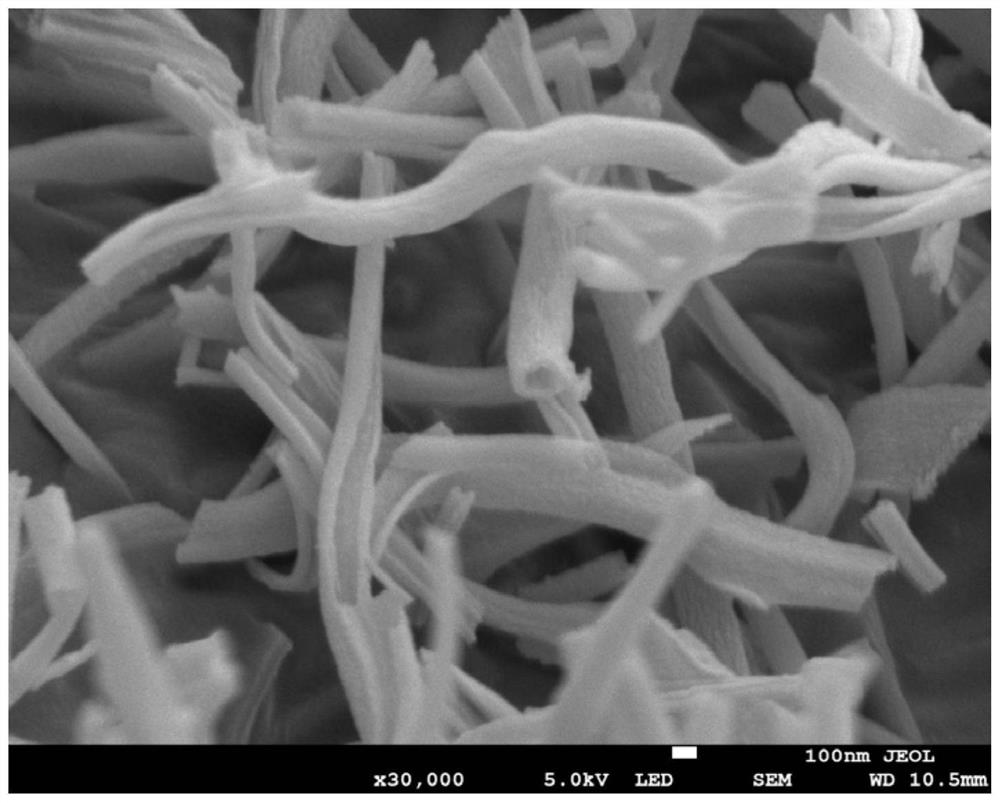

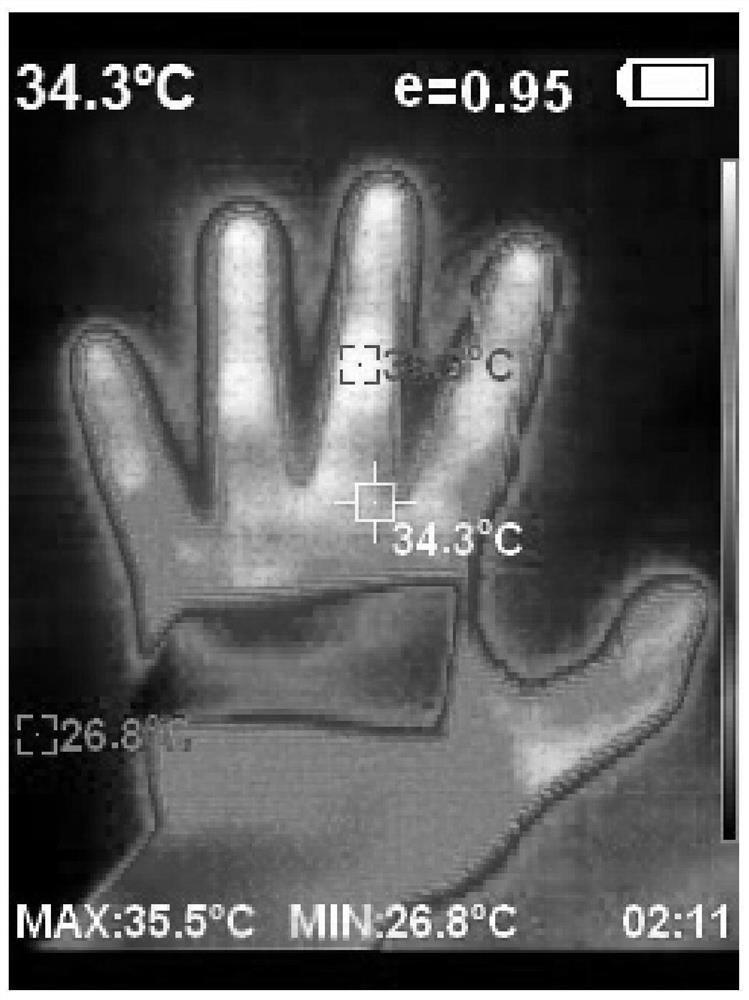

Ceramic fiber membrane, preparation method and application thereof

ActiveCN113773093AImprove shielding effectGood flexibilityInorganic material artificial filamentsFiberSpinning

The invention discloses a ceramic fiber membrane, a preparation method and application thereof. The ceramic fiber membrane is formed by interweaving hollow nano ceramic fibers. The preparation method of the ceramic fiber membrane comprises the following steps: 1) dispersing a ceramic precursor and an organic polymer in a solvent to prepare a spinning solution; and 2) carrying out electrostatic spinning by adopting a coaxial needle head, introducing the spinning solution into the outer layer of the coaxial needle head, introducing a solvent or an organic additive solution into the inner layer of the coaxial needle head, and then carrying out curing, pyrolysis and sintering to obtain the ceramic fiber membrane. The ceramic fiber membrane has excellent electromagnetic shielding and infrared stealth effects, is light, thin, good in flexibility, simple in preparation process and low in cost, can be conveniently worn by a human body and integrated into electronic devices and weapons, and has a very wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

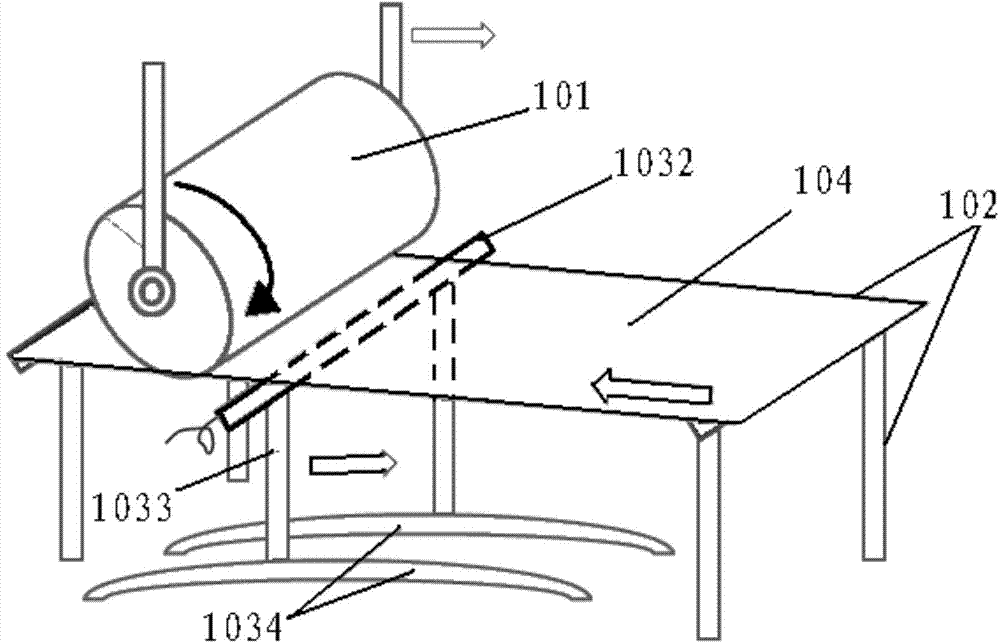

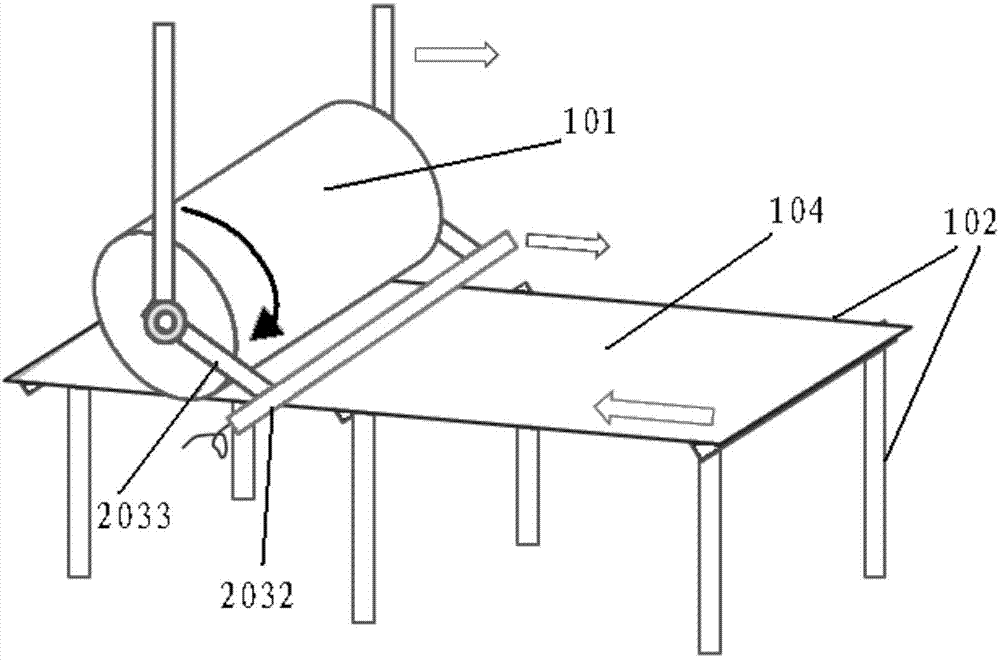

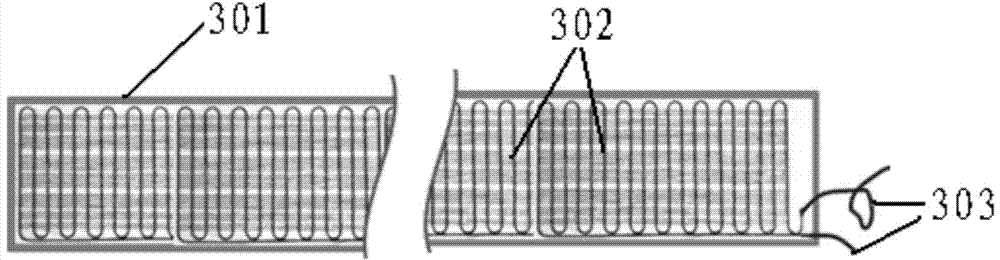

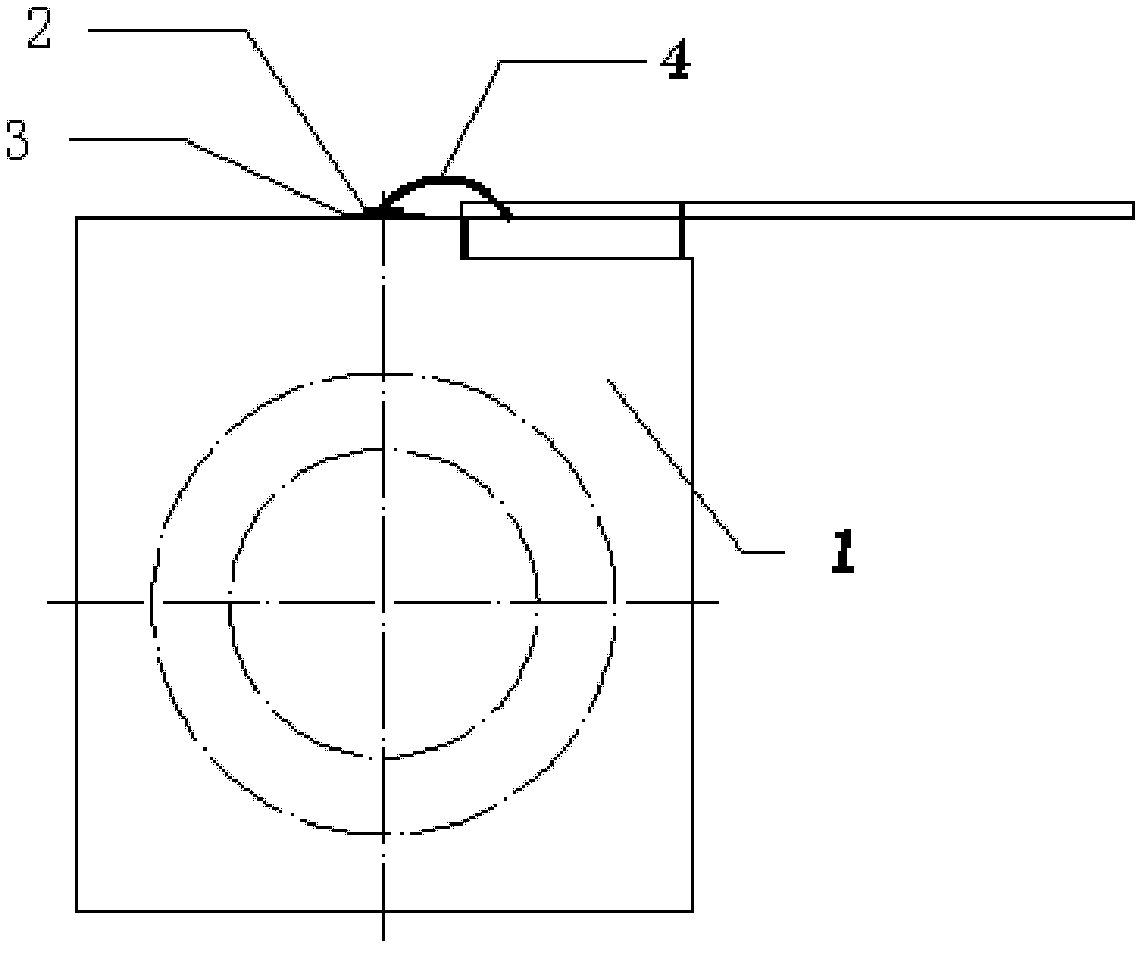

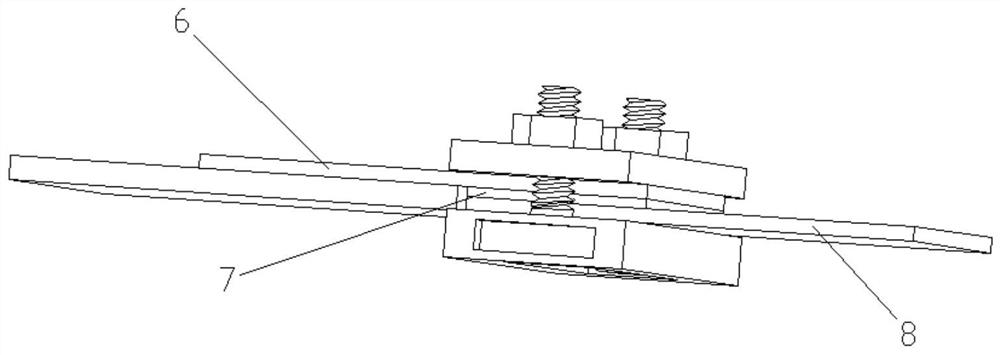

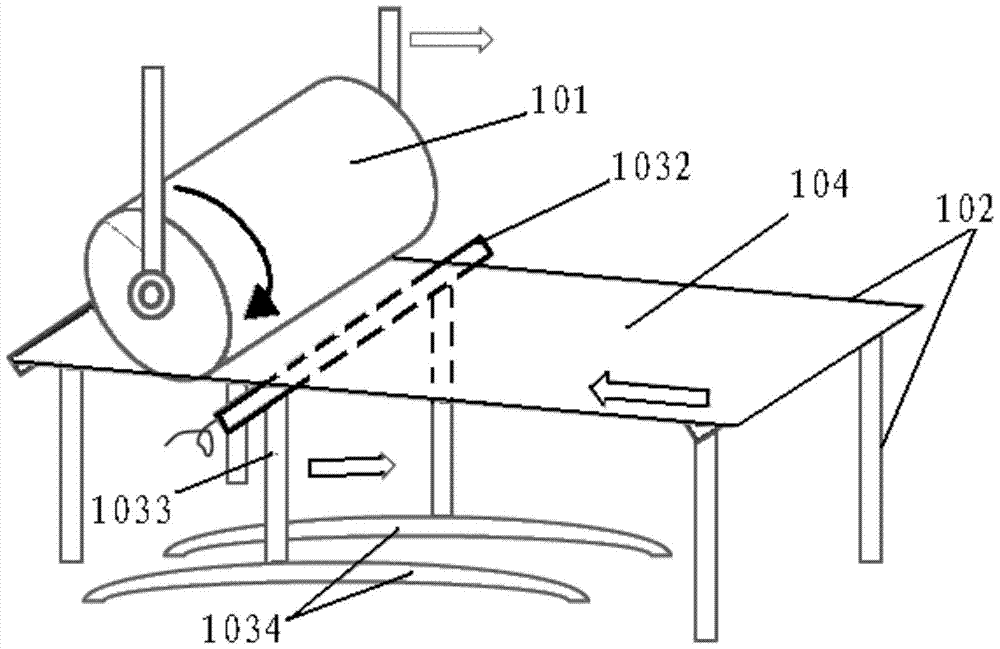

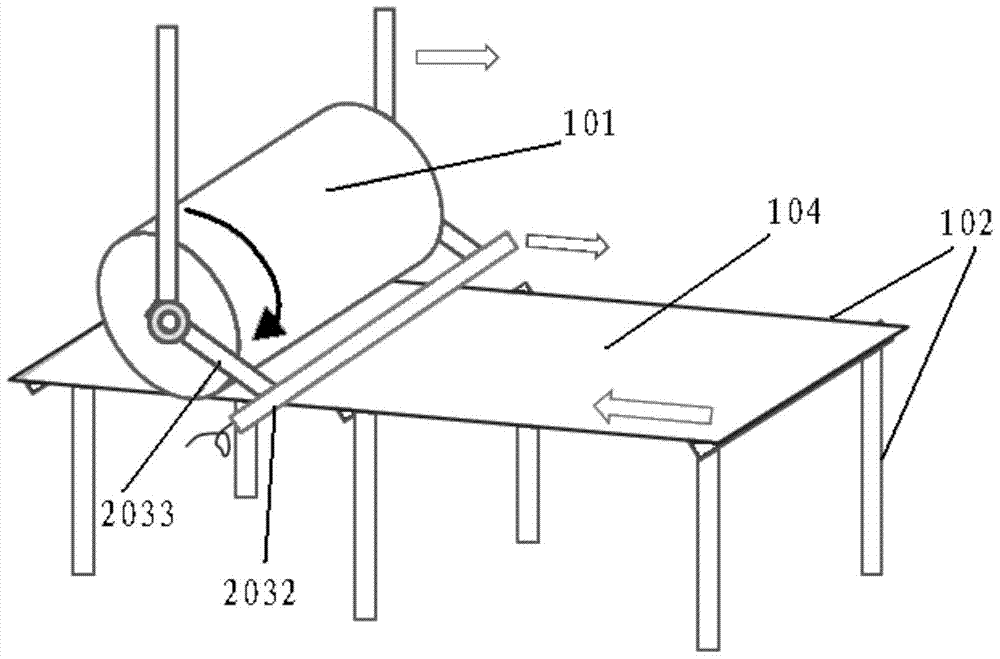

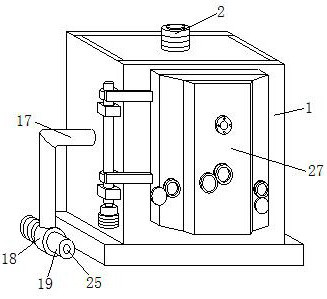

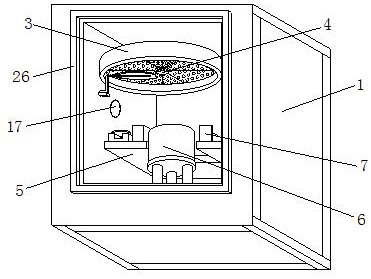

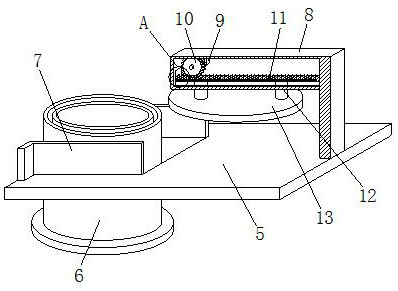

Film transfer equipment, transfer plate assembly and transfer equipment adsorption force control device

ActiveCN104708897AGood optical performanceImprove adsorption capacityTransfer printingEngineeringForming processes

The invention provides film transfer equipment, a transfer plate assembly and a transfer equipment adsorption force control device. The film transfer equipment comprises a transfer plate used for transferring a film layer to a base plate for the film layer to be transferred, and a base station used for bearing the base plate. The film transfer equipment further comprises an adsorption force control unit, wherein the adsorption force control unit acts on at least one of the base plate and / or the transfer plate in the transferring process so as to increase the difference between first adsorption force of the base plate to film forming matter transferred out from the transfer plate and second adsorption force generated by the transfer plate to the film forming matter. The film transfer equipment, the transfer plate assembly and the transfer equipment adsorption force control device can reduce residue and particle phenomena in the transferring and film forming processes through a simple and low-cost method.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

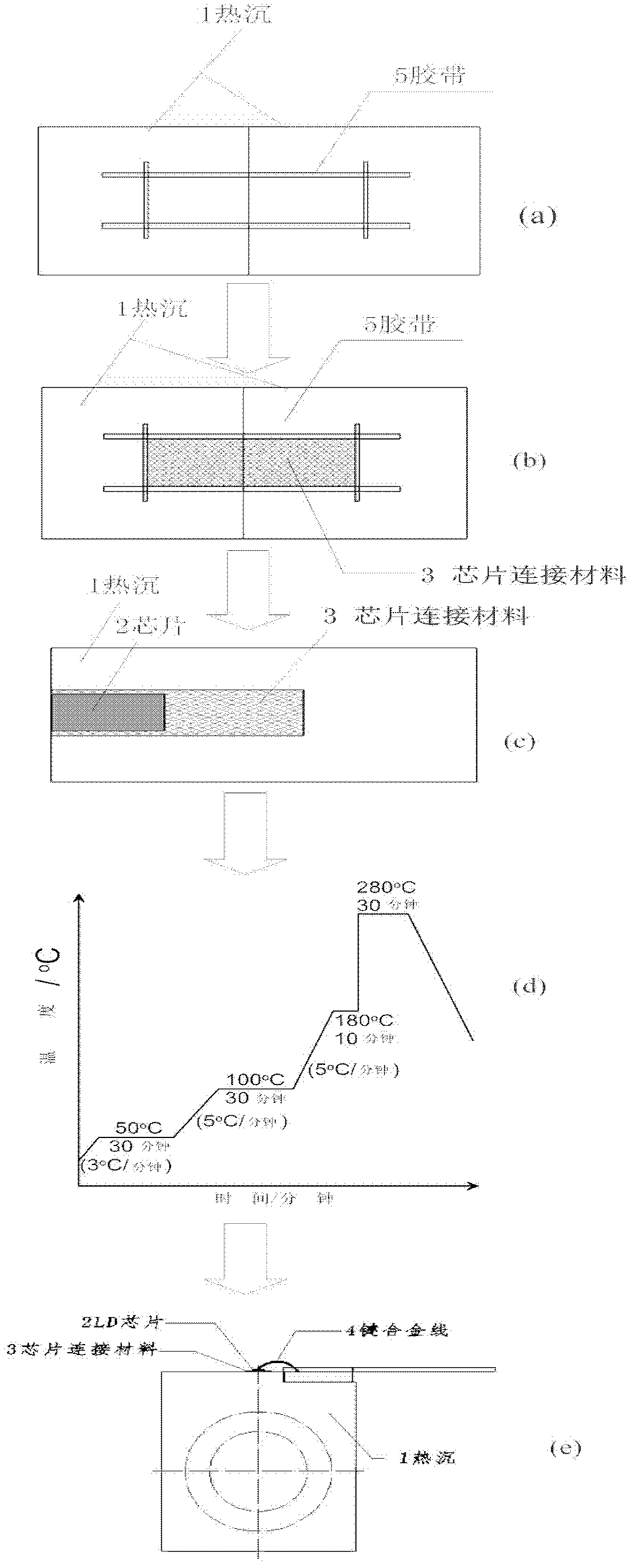

Laser diode packaging module and packaging method

InactiveCN102510005ASave time for coatingControl film thicknessSemiconductor laser structural detailsHeat sinkSilver paste

The invention discloses a laser diode (LD) packaging module and a LD packaging method. An LD chip is packaged on a heat sink, nano-silver paste is adopted as a connecting material for the heat sink and the LD chip, and the heat sink is connected with the LD chip through a bonded gold wire to form a negative electrode. In a packaging process, a silk screen printing mold is simulated by an adhesive tape, so that the coating area and thickness of the nano-silver paste are controlled by controlling the arrangement range and thickness of the adhesive tape. The LD chip is connected by a low-temperature sintering technology, and the nano-silver paste is adopted as the connecting material for the LD chip, so that a film can be conveniently plated by a silk screen printing method, film plating time can be effectively saved, and the thickness of the film can be controlled. The connecting material for the LD chip is pure silver, so that the LD packaging module has low thermal resistance, a high integration degree and high photoelectric conversion efficiency, and is energy-saving and environment-friendly.

Owner:TIANJIN UNIV

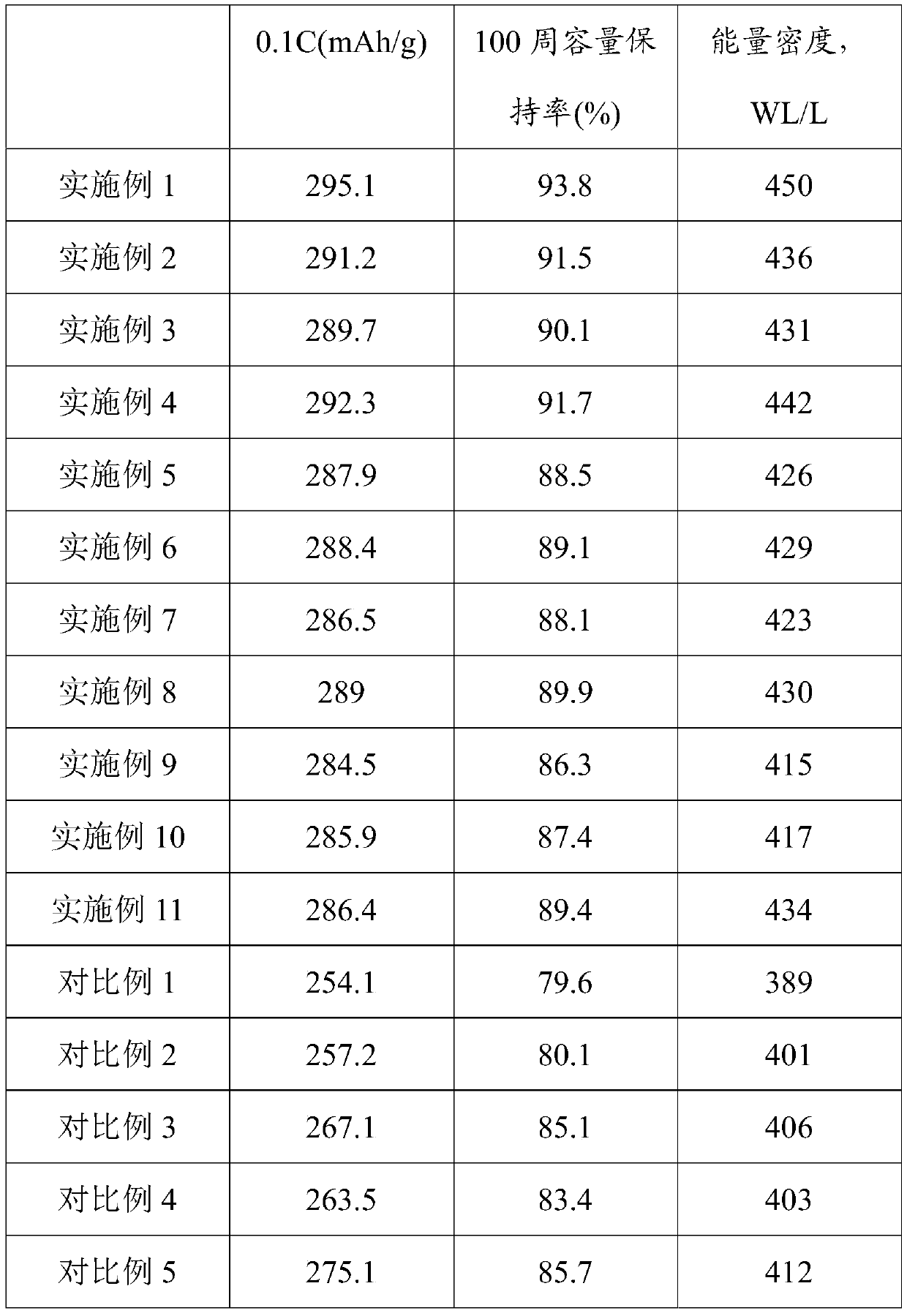

Lithium-rich manganese-based positive electrode material, and preparation method and use thereof

ActiveCN109956505AControl film thicknessReduced flexibilityCell electrodesSecondary cellsLithiumManganese

The invention discloses a lithium-rich manganese-based positive electrode material, and a preparation method and a use thereof. The lithium-rich manganese-based positive electrode material is a flexible lithium-rich manganese-based positive electrode material, and does not contain other inert components, so the energy density is obviously improved. The preparation method of the lithium-rich manganese-based positive electrode material comprises the following steps: mixing a lithium source with a manganese-based material, carrying out stripping and centrifuging treatment to obtain a lithium-richmanganese-based positive electrode material suspension, coating a substrate with the suspension, and carrying out vacuum drying to obtain the lithium-rich manganese-based positive electrode material.The lithium-rich manganese-based positive electrode material regulates the thickness and the flexibility of the product film by controlling the coated weight and vacuum drying conditions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

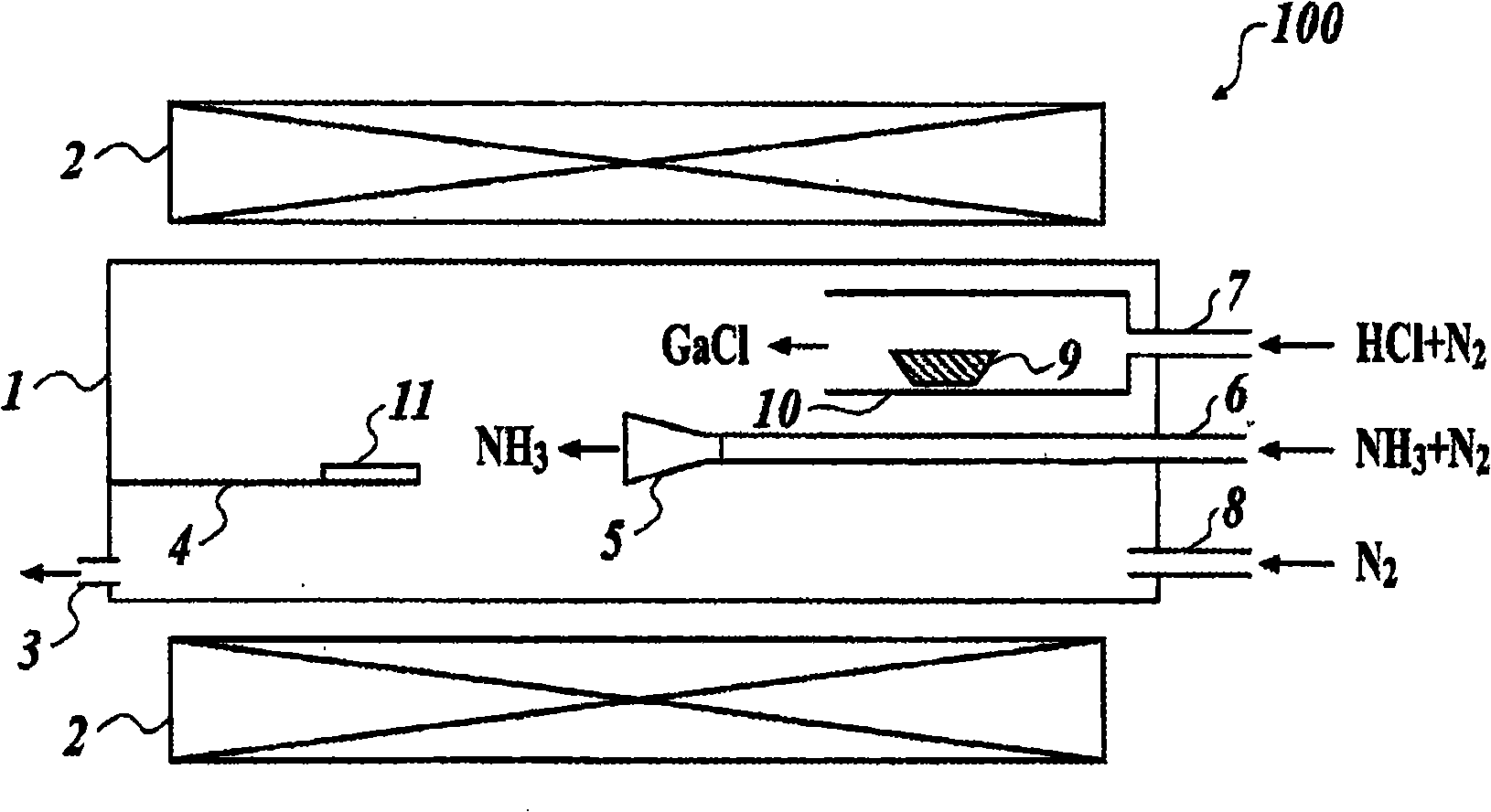

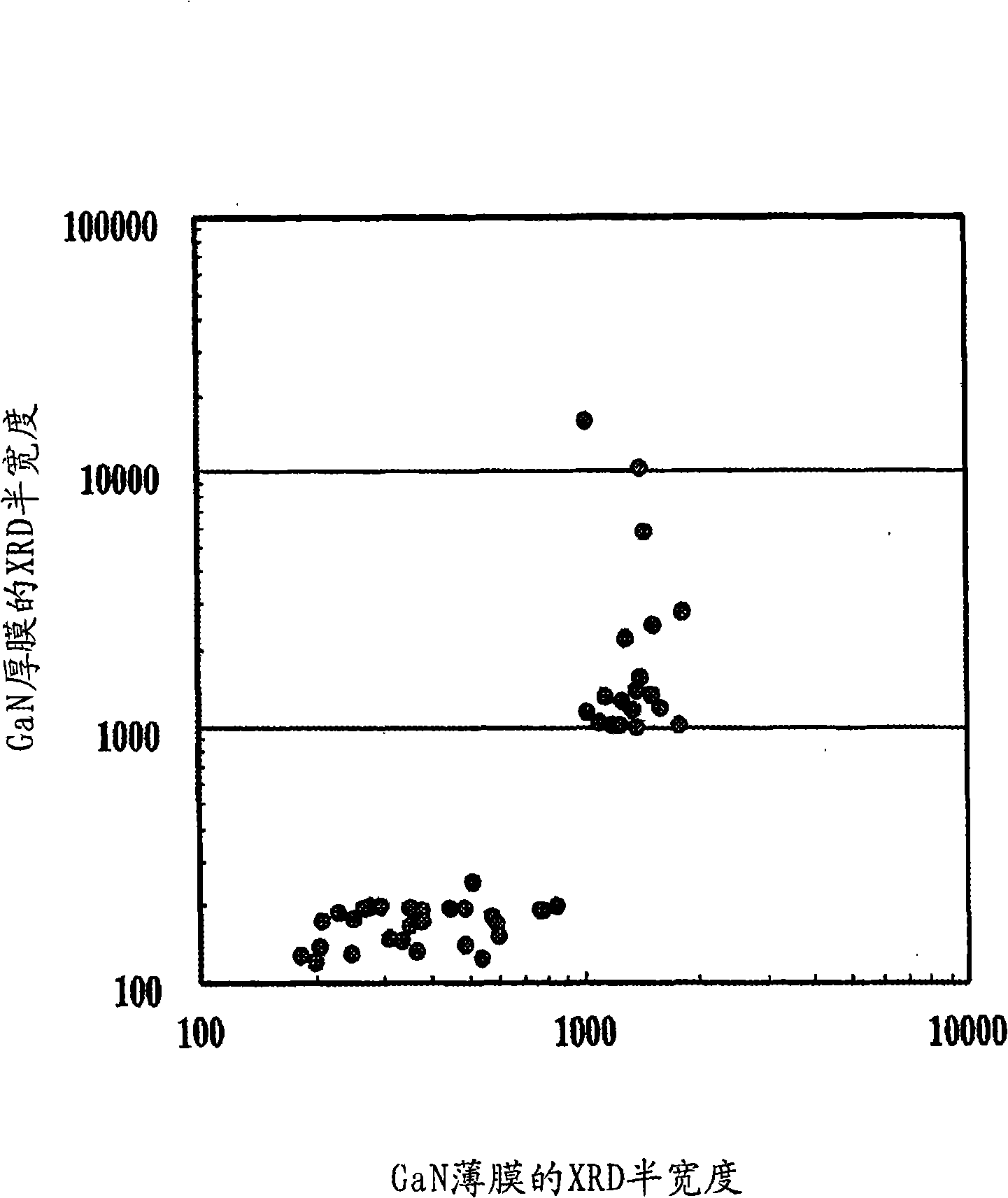

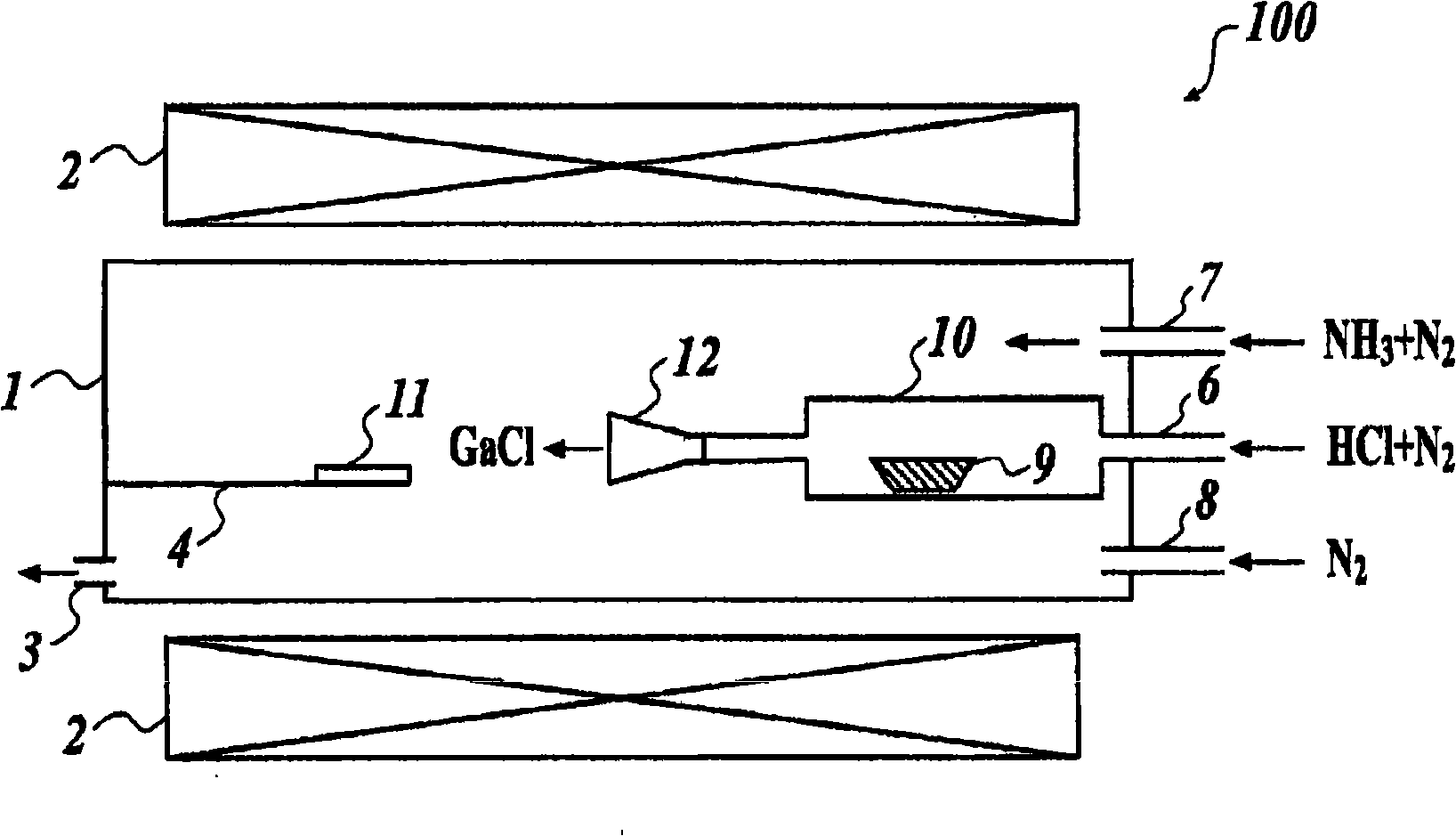

Process for producing gan single-crystal, gan thin-film template substrate and gan single-crystal growing apparatus

InactiveCN101517134AInhibit growthControl film thicknessPolycrystalline material growthSemiconductor/solid-state device manufacturingOptoelectronicsSingle crystal

Provided are a manufacturing method of a GaN single crystal in which the film thickness of the GaN single crystal can be controlled accurately, even when a hydride vapor phase epitaxy is applied; a GaN thin film template substrate which is suitable for growing a GaN thick film with a fine property; and a GaN single crystal growing apparatus. Provided is a manufacturing method of a GaN single crystal by a hydride vapor phase epitaxy, wherein the hydride vapor phase epitaxy comprises: spraying HCl (hydrogen chloride) onto Ga (gallium) which is heated and fused in a predetermined temperature to generate GaCl (gallium chloride); and forming a GaN thin film by a reaction of the generated GaCl (gallium chloride) with NH 3 (ammonia) gas which is hydroxide gas on a substrate, the manufacturing method comprising supplying the NH 3 gas in a vicinity of the substrate (for example, at a position which is separated from the substrate by a distance of 0.7-4.0 times as longer than a diameter of the substrate) through a nozzle. Further, as the substrate, an NGO(011) substrate in which the lattice constant thereof is similar to that of GaN is used.

Owner:JX NIPPON MINING & METALS CO LTD

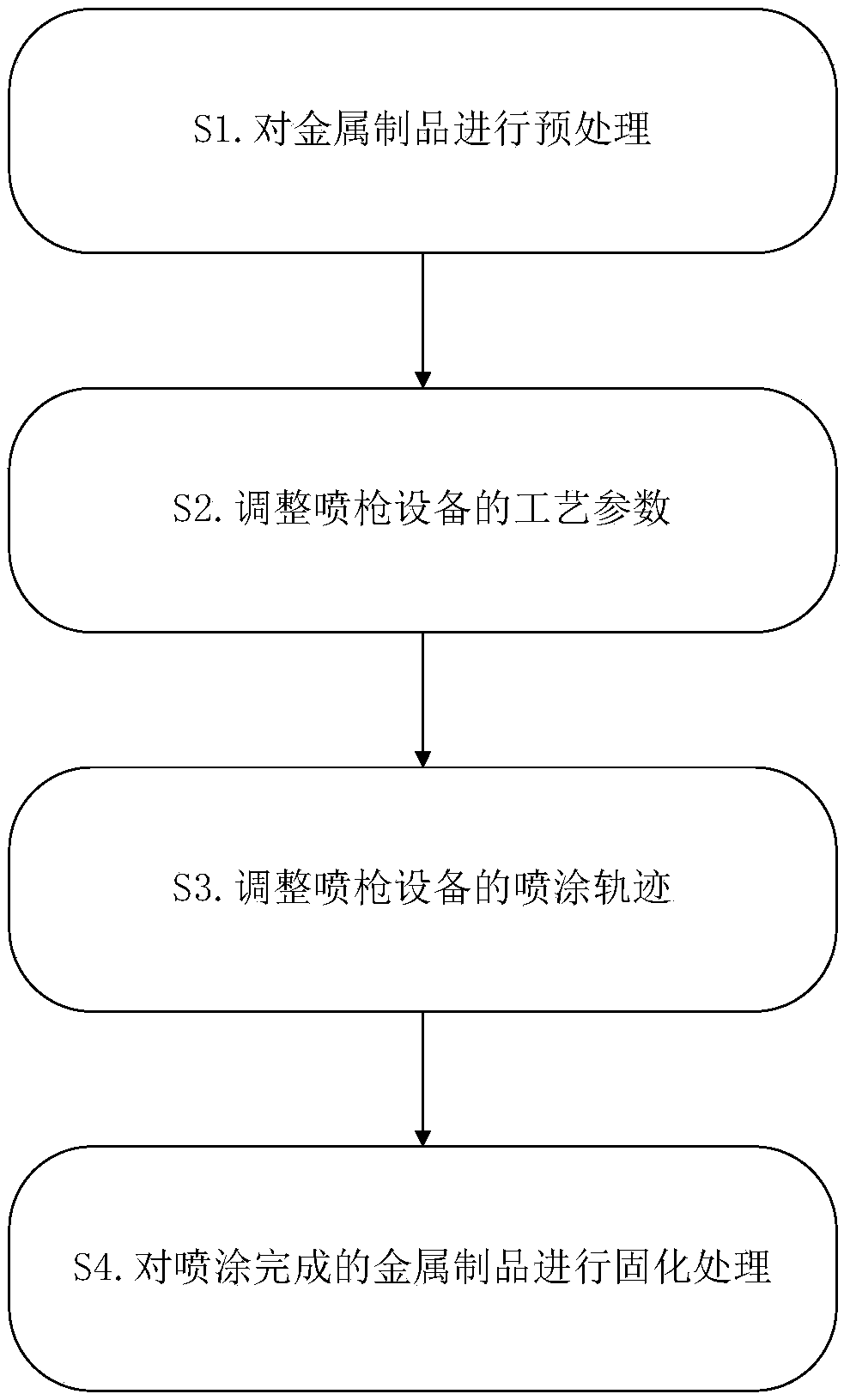

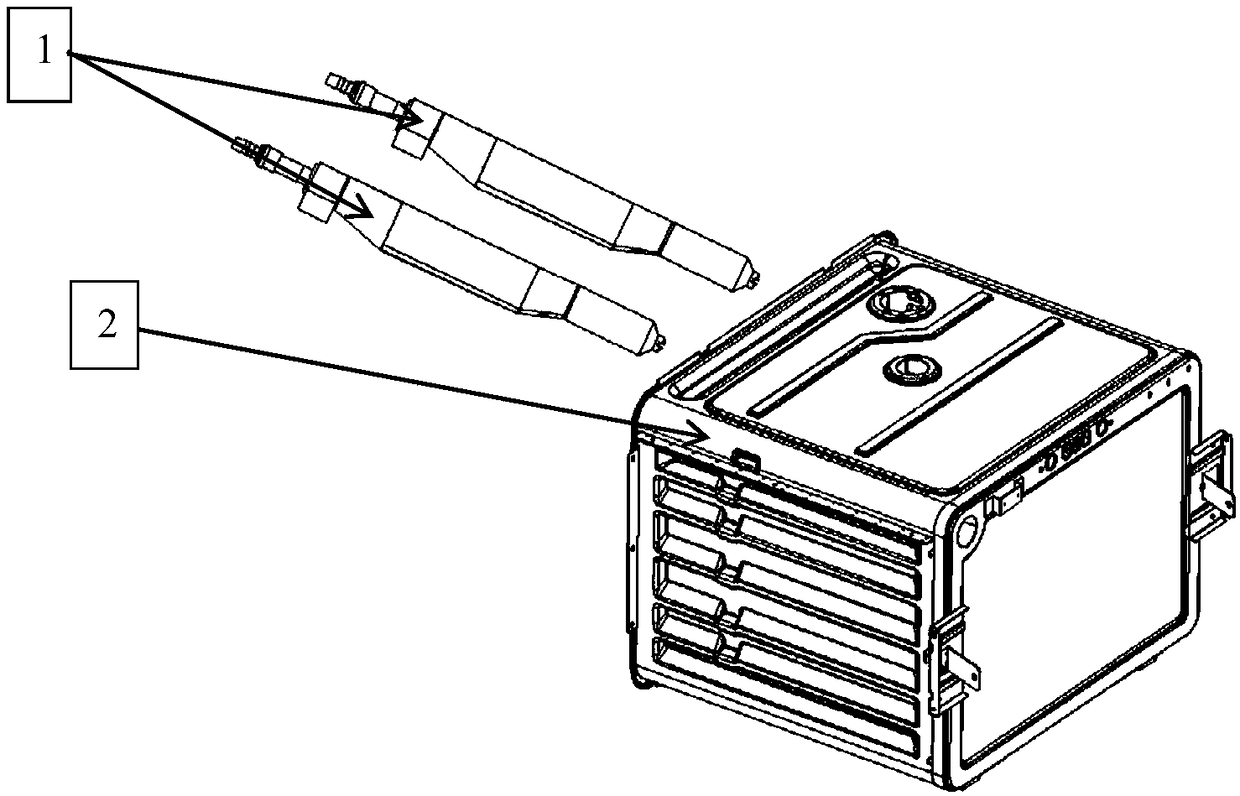

Enameling technique for metal product

InactiveCN108453021AControl film thicknessHigh glossPretreated surfacesCoatingsPre treatmentMachining

The invention relates to an enameling technique for a metal product. The enameling technique for the metal product comprises the following steps that S1, the metal product is pretreated, so that the adhesion effect of enameling powder is improved; S2, process parameters of a spraying gun device are adjusted, so that the adhesion rate of the enameling powder is increased; S3, the spraying track ofthe spraying gun device is adjusted, so that an overlapped spraying effect is achieved, and the spraying effect is improved; and S4, the metal product sprayed with the enameling powder is cured. According to the enameling technique, the metal product is pretreated, the process parameters and the spraying track of the spraying gun device are adjusted in the further spraying process, and finally, the metal product is cured, so that the film thickness of the metal product is effectively controlled, and the glossiness of the metal product is effectively improved; and meanwhile, the machining difficulty is lowered, and the work efficiency is effectively improved.

Owner:广州泽亨实业有限公司

Novel LED heat dissipating lamp shell for daily lighting and production method thereof

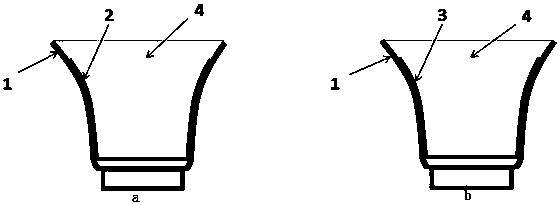

InactiveCN107687580AEfficient deliveryEasy to passLighting heating/cooling arrangementsGlobesThermal expansionEngineering

The invention discloses a novel LED heat dissipating lamp shell for daily lighting and a production method thereof. The novel LED heat dissipating lamp shell comprises a plastic lamp shell, and the inner surface of the plastic lamp shell is coated with a carbon-based heat-conduction material layer. A carbon-based heat-conduction material of the carbon-based heat-conduction material layer is prepared through the following steps that a heat-conduction material, water and a substance A are taken and mixed to be added into a container to be mixed and stirred, and evenly-mixed viscous mixed liquidis obtained; and part of a solvent in the viscous mixed liquid is removed to enable the viscosity range to be within 1-5000 cP, and then the carbon-based heat-conduction material is obtained. According to the novel LED heat dissipating lamp shell, heat of a luminous LED chip can be effectively and rapidly transmitted to the whole plastic surface to achieve the extremely good heat dissipating effect so that an internally-arranged aluminum cup heat dissipating structure of a traditional LED lamp shell can be completely substituted, the cost is greatly reduced, and the unavoidable difficult problems of cracking of outer-layer plastics and the like which are caused by the thermal expansion coefficient difference between an inner-layer aluminum cup and the outer-layer plastics are solved.

Owner:阮伟

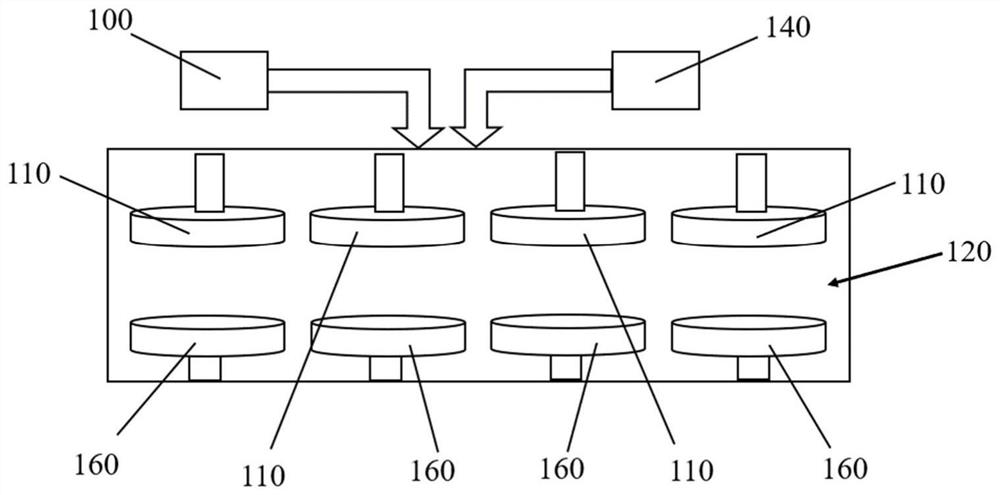

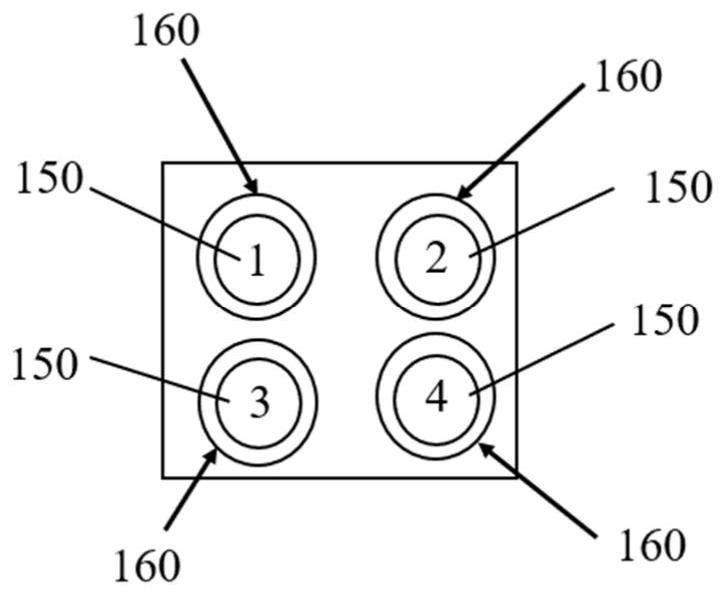

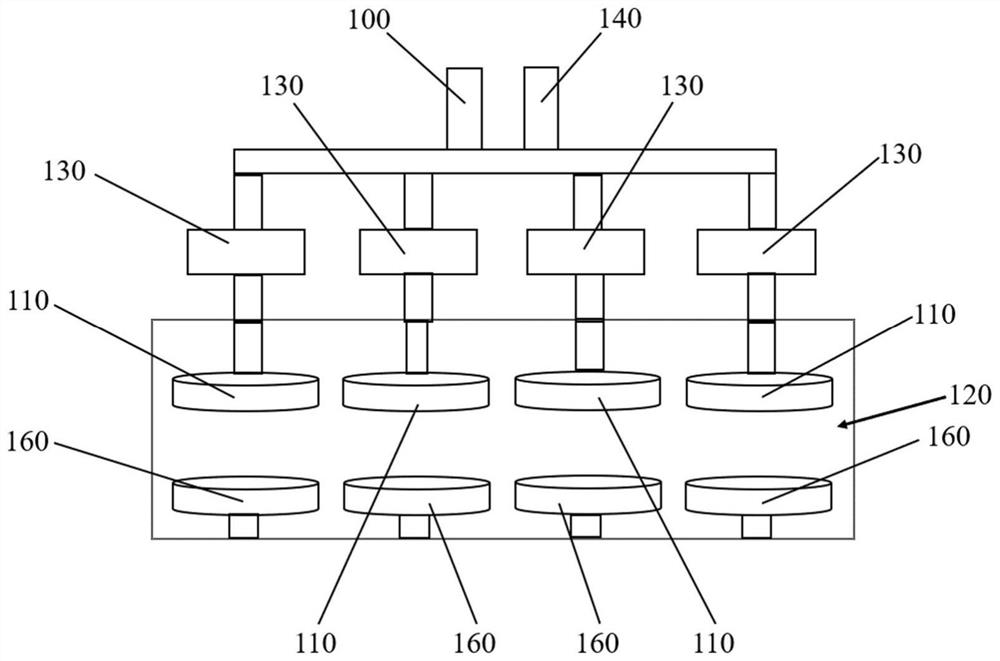

Chemical vapor deposition equipment

PendingCN113584465AQuality improvementControl film thicknessChemical vapor deposition coatingFinal product manufacturePhysicsThin membrane

The invention provides chemical vapor deposition equipment, and belongs to the technical field of semiconductors. The chemical vapor deposition equipment comprises a reaction cavity, a gas supply assembly, gas distribution discs and gas control assemblies. The reaction cavity is provided with a plurality of bearing tables used for bearing wafers. The gas supply assembly is used for providing reaction gas. The plurality of gas distribution discs are arranged in one-to-one correspondence with the plurality of bearing tables. The plurality of gas control assemblies are arranged in one-to-one correspondence with the plurality of gas distribution discs. The gas distribution discs and the gas supply assembly are connected through the corresponding gas control assemblies. In this way, the flow or ventilation time of the reaction gas can be adjusted through the gas control assemblies so as to control the gas flow or ventilation time of the corresponding gas distribution discs, the difference of the film thickness of films deposited on the surfaces of different wafers is reduced, the quality of the films deposited on the wafers can be improved, and then the cost is reduced.

Owner:CHANGXIN MEMORY TECH INC

Method for preparing anhydrous proton exchange film based on sulfonated graphene oxide by utilizing spin-coating technology

ActiveCN110620253AImprove proton conductivityControl film thicknessFinal product manufactureFuel cellsComposite filmFuel cells

The invention belongs to the technical field of a fuel cell and particularly relates to a method for preparing an anhydrous proton exchange film based on sulfonated graphene oxide by utilizing the spin-coating technology. The method comprises steps of preparing polyvinyl chloride (PVC) solution, preparing graphene oxide (SGO) solution, uniformly coating the PVC solution on a surface of a glass plate by using a spin coater, dropwise adding the SGO solution, repeating a spin coating step for 5 times, and drying to prepare the PVC / SGO 5 composite film. And soaking in PA (Polyamide) with the massfraction of 85% for 24-48 hours to prepare the PVC / SGO (Polyvinyl Chloride / Styrene Glycol)5 / PA composite film. The method is advantaged in that the non-aqueous proton exchange film having high mechanical property, good proton conductivity and the like is prepared by utilizing the spin-coating technology based on excellent conductivity of the SGO and controllable thickness of a film material prepared by the spin-coating technology and the like, and the method has the good application prospect.

Owner:NORTHEASTERN UNIV

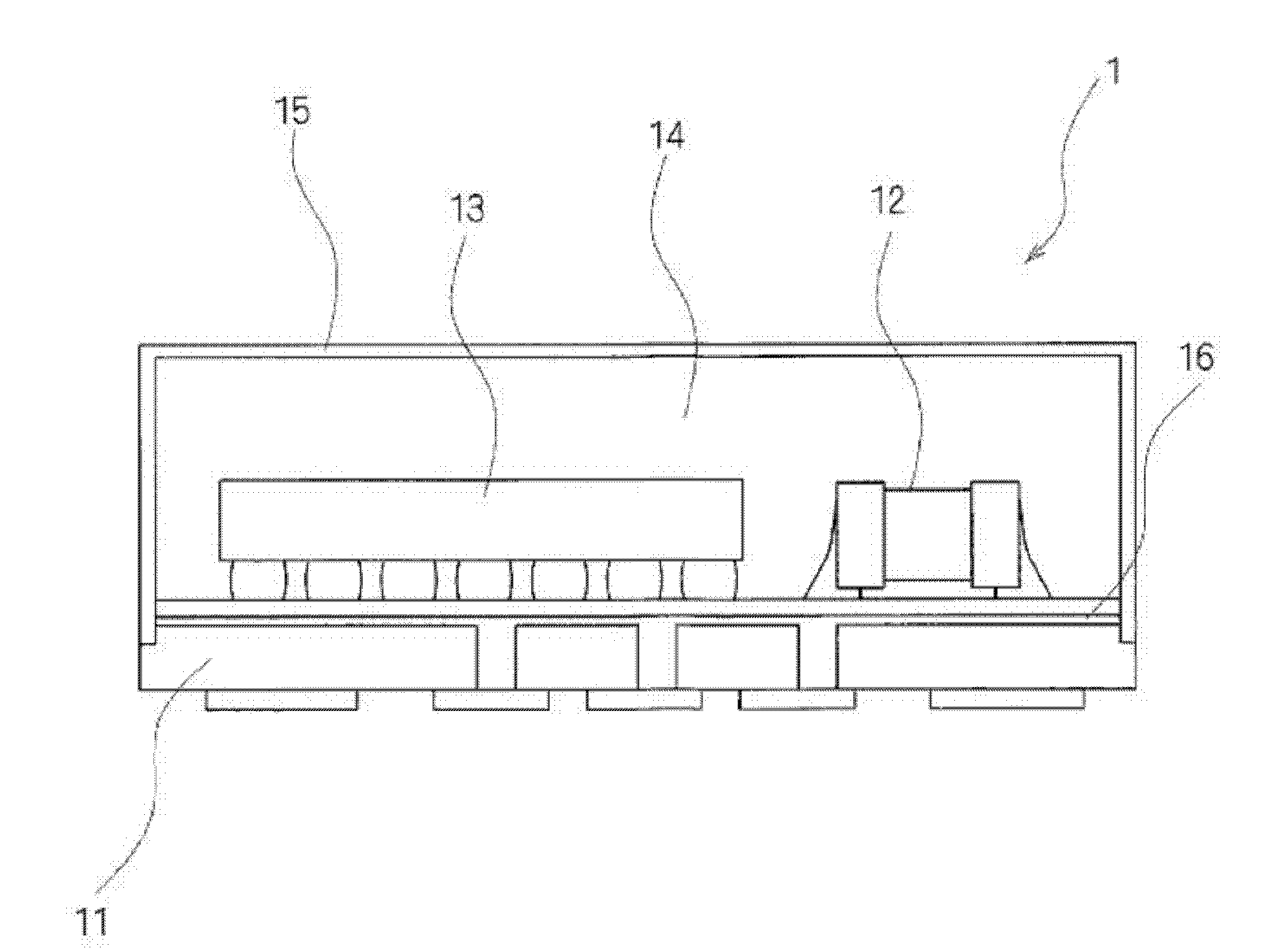

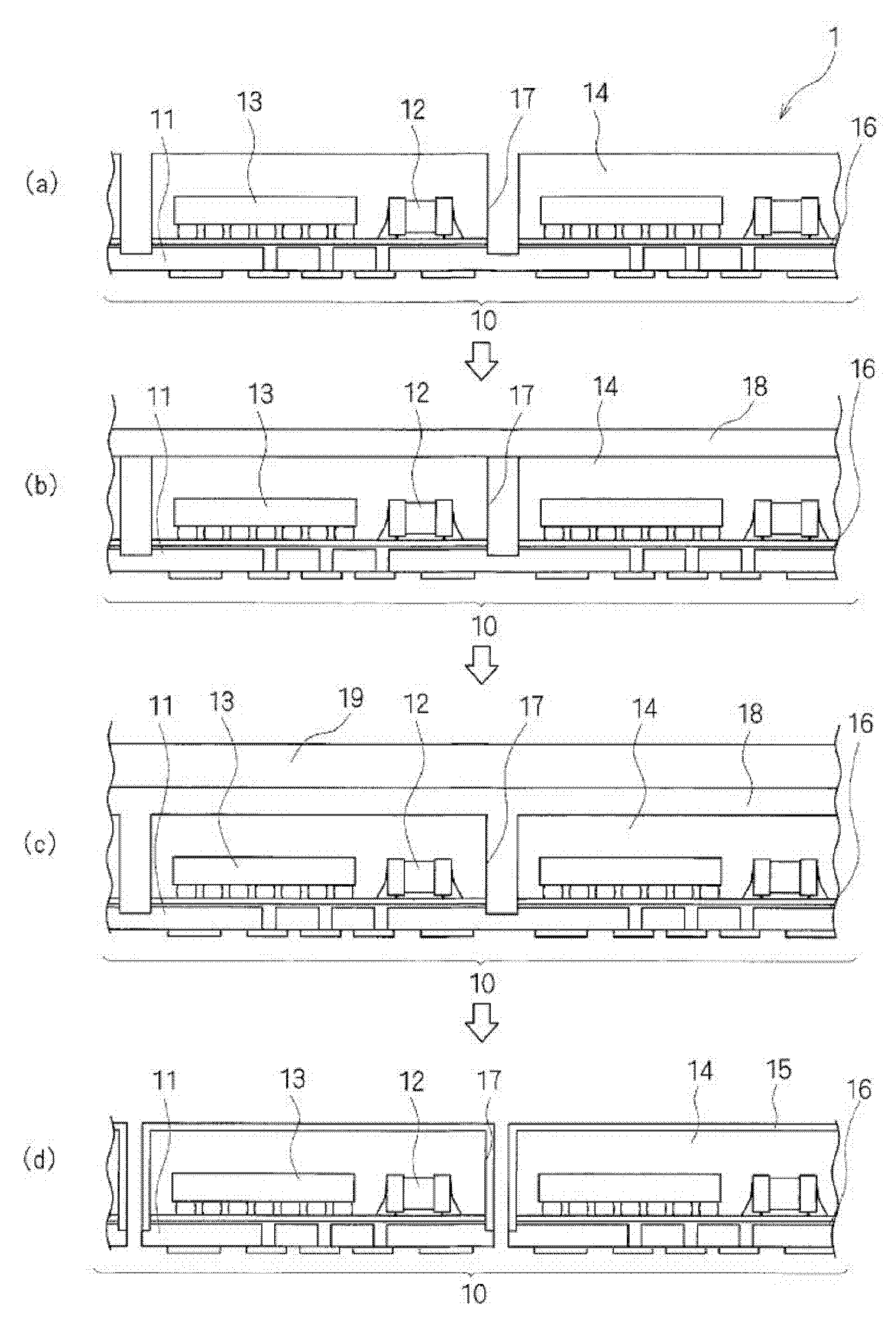

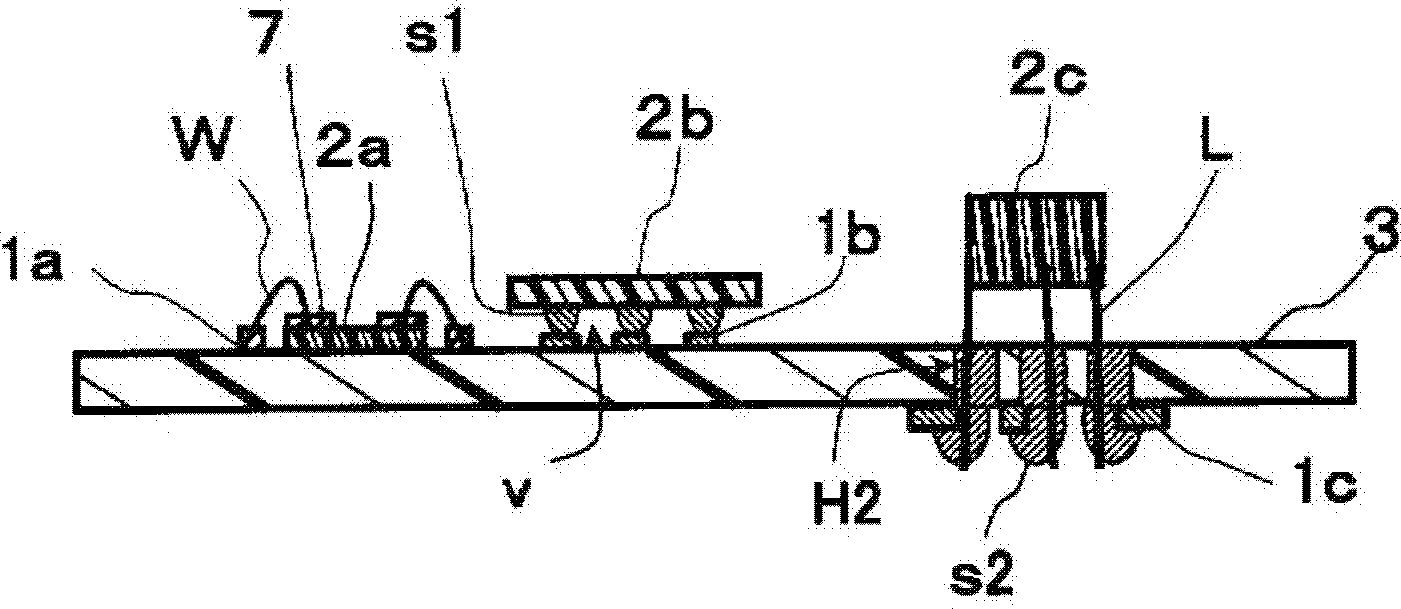

Manufacturing method of electronic parts module

ActiveCN102203926BAchieve thin filmAchieve thinningSemiconductor/solid-state device detailsCross-talk/noise/interference reductionMiniaturizationElectronic component

Owner:MURATA MFG CO LTD

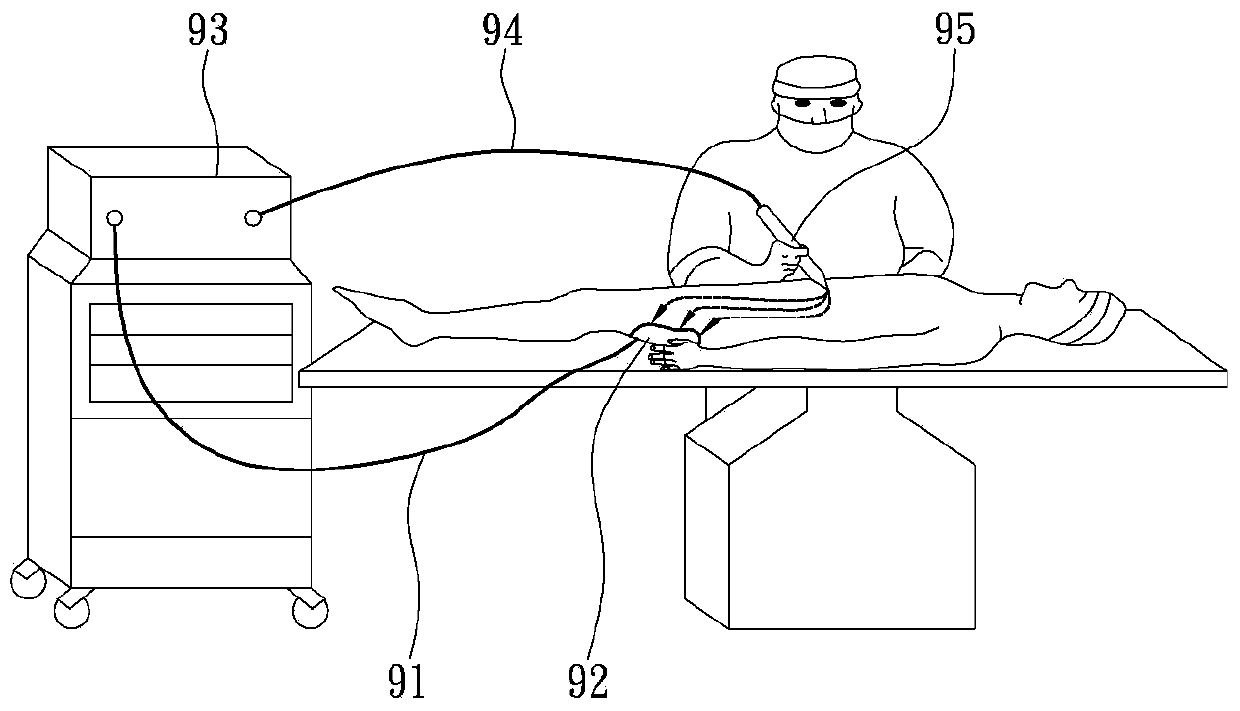

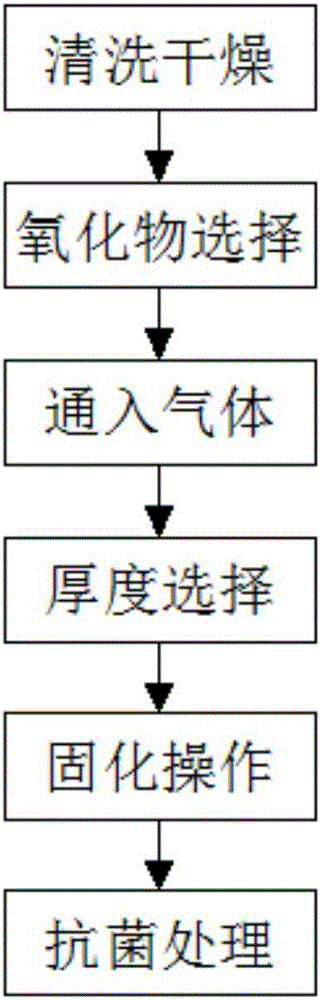

ALD technology-based energy saving method for producing oxidation layer on medical device

InactiveCN106581782AImprove stabilityImprove compactnessSurgeryChemical vapor deposition coatingChemical reactionGas phase

An ALD technology-based energy saving method for producing an oxidation layer on a medical device concretely comprises the following steps: 1, cleaning and drying; 2, oxide selection; 3, gas introduction; 4, thickness selection; 5, solidification; and 5, antibacterial treatment. A gas phase is alternately introduced to a reactor through an atom layer deposition technology and undergoes a chemical reaction to form a film. An oxidation layer with the thickness of 100-200 nm is produced on the surface of an implantable alloy medical device, has very good stability and compactness, changes the adhesiveness, the biocompatibility and the blood compatibility, and avoids new medical problems caused by influences of shedding and cracking phenomena of a polymeric drug delivery layer of the implantable alloy medical device and non-degradable polymeric materials on functions of human bodies in in-vivo environment and in the expansion process of a scaffold.

Owner:天津丰茂科技有限公司

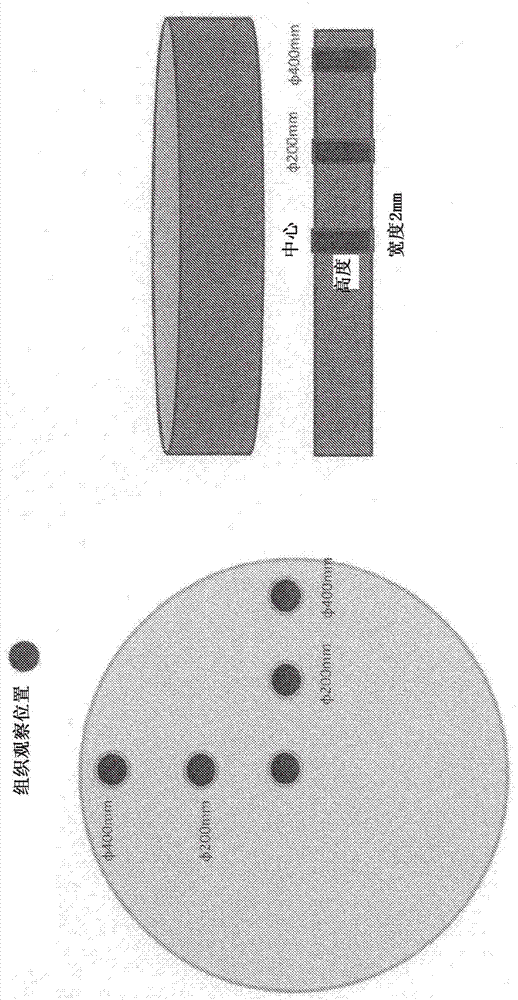

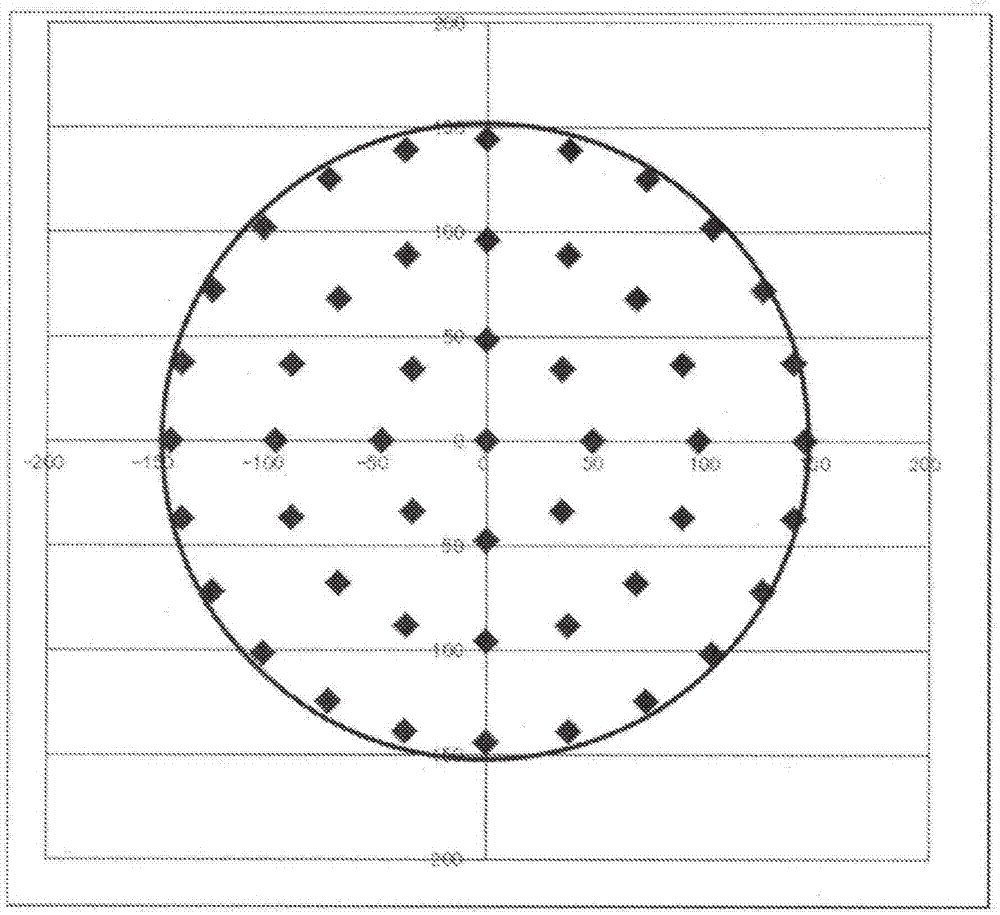

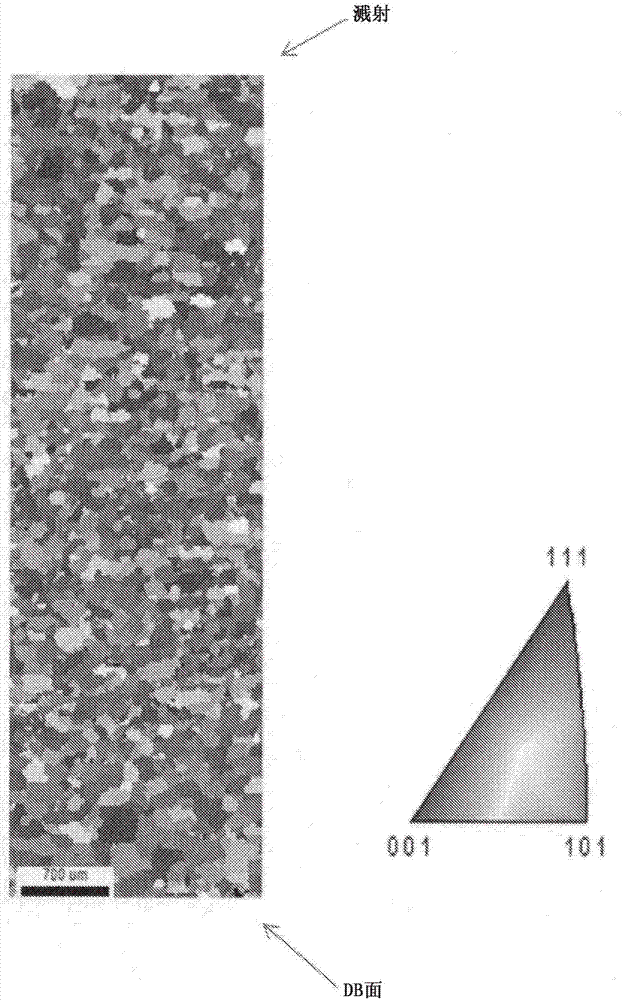

Tantalum sputtering target, and production method therefor

ActiveCN107109634AImprove film thickness uniformityReduce film formation speedElectric discharge tubesVacuum evaporation coatingSputteringThin membrane

When backscattered electron diffraction is used to observe the normal direction ND of the rolling surface, i.e. a cross section orthogonal to the sputtering surface of the target, this tantalum sputtering target has an area ratio of crystal grains of which the {100} plane is oriented in ND of at least 30%. The present invention addresses the problem of providing a tantalum sputtering target with which the film-formation rate can be suitably controlled under high-power sputtering conditions. When such a tantalum target is used to form a film by way of sputtering, a thin film exhibiting excellent film-thickness uniformity can be formed, and productivity of the thin film formation process can be improved, even with regard to fine wiring.

Owner:JX NIPPON MINING & METALS CORP

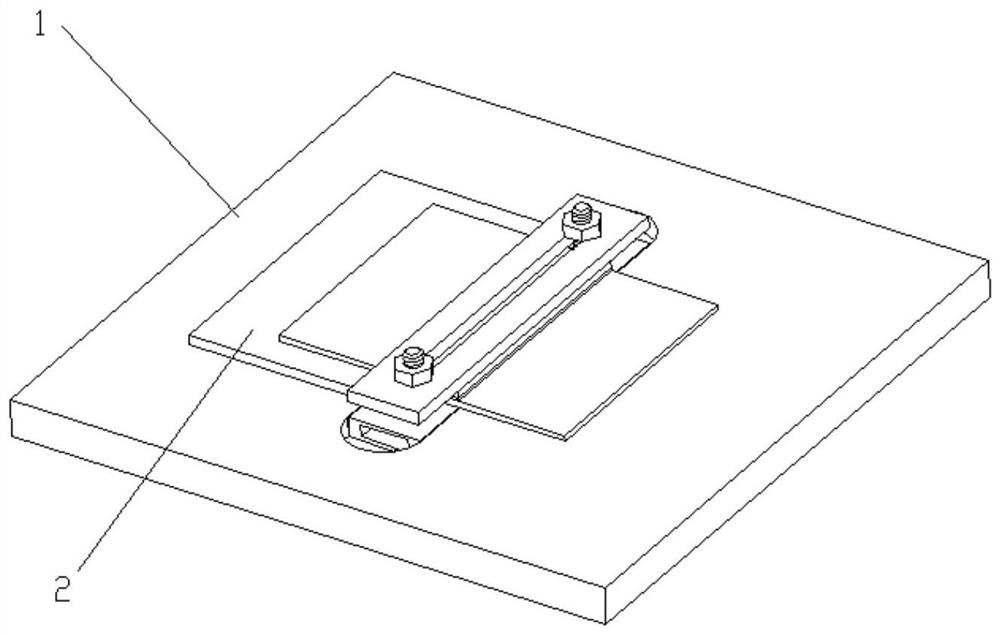

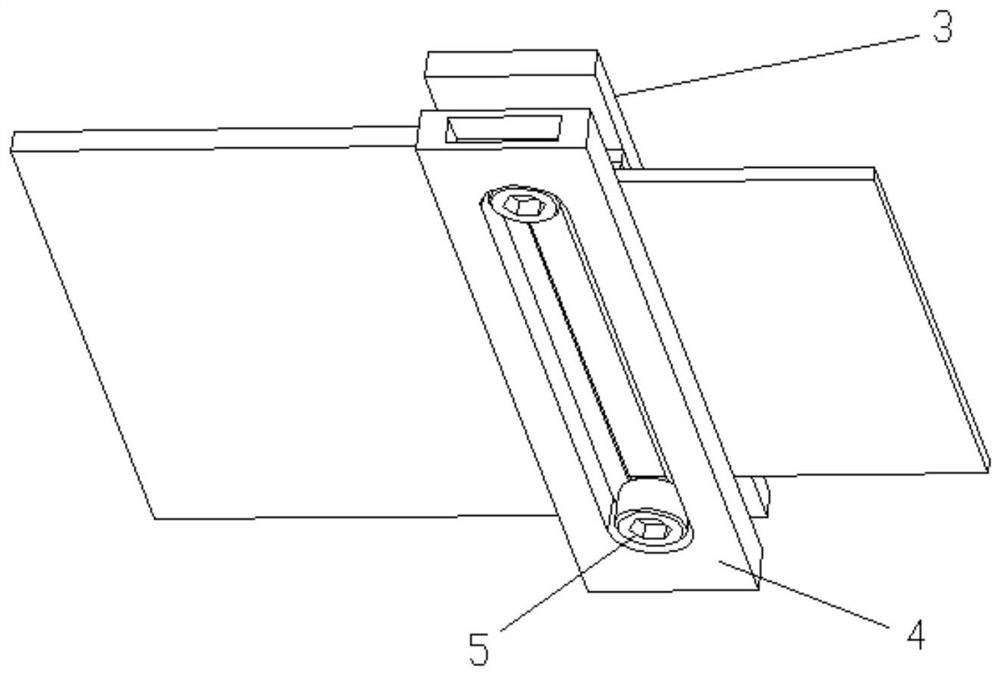

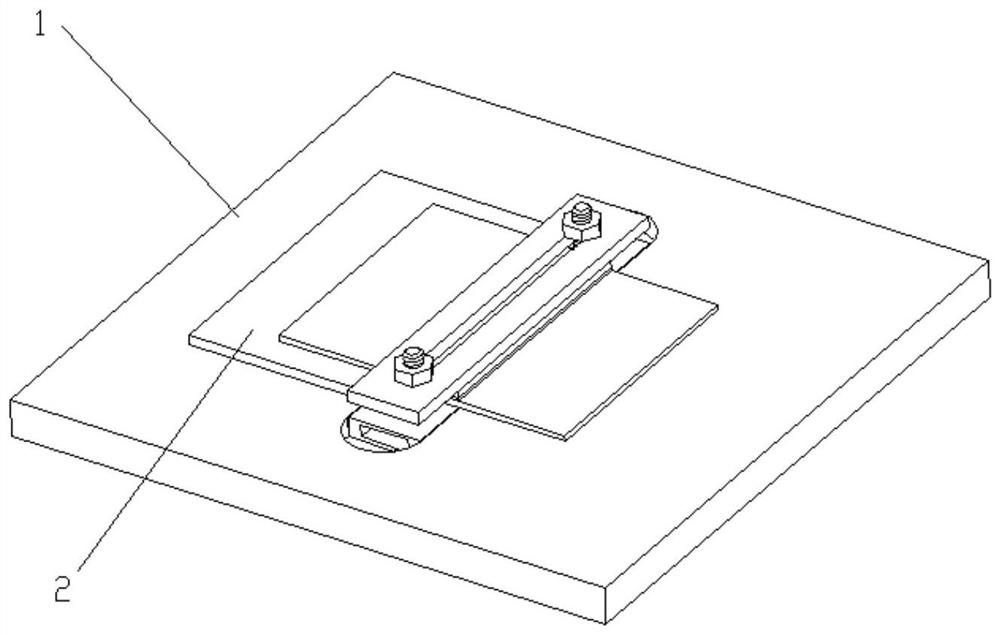

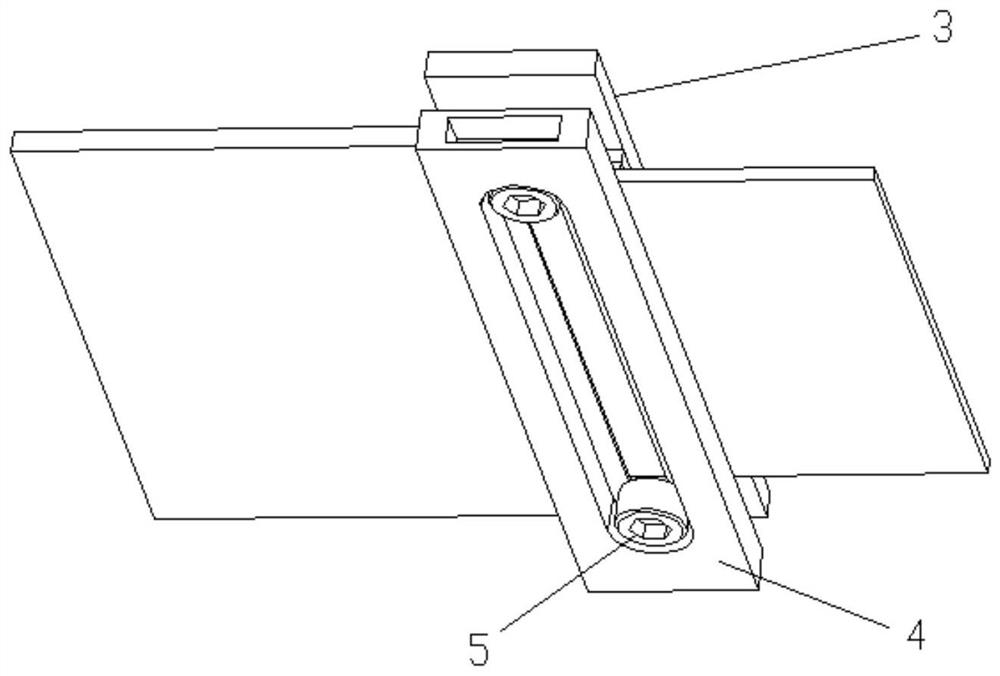

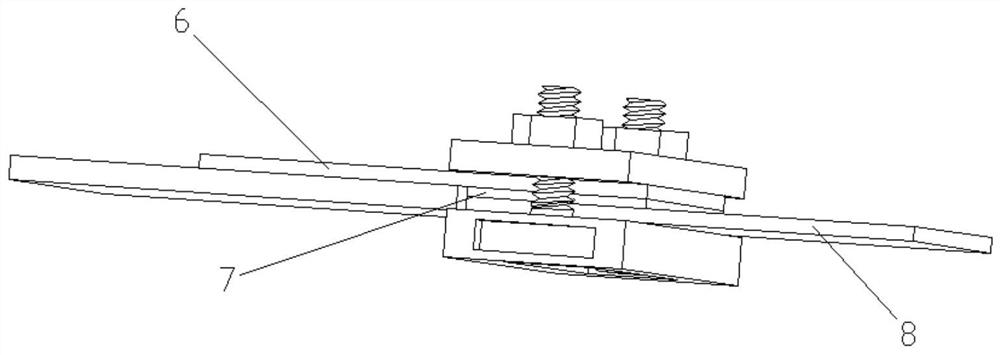

Method for controlling thickness of adhesive film

ActiveCN113333243ASolve uneven bondingSimple structureMaterial gluingPretreated surfacesPolymer chemistryPolytetrafluoroethylene

The invention provides a method for controlling the thickness of an adhesive film. The method comprises the step of using an adhesive film thickness control device and comprises the following steps that firstly, a proper thickness difference mold plate is selected; then, adhesive, an upper connecting plate and a lower connecting plate are arranged on the adhesive film thickness control device; and polytetrafluoroethylene cloth, an isolating film and breathable felt are sequentially laid on the surfaces of the adhesive film thickness control device and the connected upper connecting plate and lower connecting plate, the whole adhesive film thickness control device, the connected upper connecting plate and lower connecting plate are wrapped and then put into a vacuum bag, the adhesive film thickness control device, the connected upper connecting plate and lower connecting plate and the vacuum bag are put into an autoclave together, then, adhesive bonding curing forming of the upper connecting plate and the lower connecting plate is completed in the autoclave, and an adhesive bonding piece is taken out so that the thickness of the adhesive film used for connection between the upper connecting plate and the lower connecting plate can be the target thickness of the adhesive film. According to the method, the thickness of the adhesive film in the adhesive bonding process of a composite material can be well controlled, and therefore the adhesive bonding strength of a connecting joint of the composite material is effectively controlled, and the problem that adhesive bonding unevenness is prone to happening in the adhesive bonding connecting process of the composite material is effectively solved.

Owner:CENT SOUTH UNIV

Gumming procedure of steel plate film-covering technology

InactiveCN108940719AAvoid the problem of uneven glue applicationApply glue evenlyLiquid surface applicatorsSpraying apparatusSheet steelImpurity

The invention discloses a gumming procedure of steel plate film-covering technology. The gumming procedure of the steel plate film-covering technology comprises the steps of glue mixing, glue injecting and gumming. The surface of coating roller is wiped up by non-woven fabric dipping thinning agent before gumming to enable the surface of the coating roller to be smooth, no glue and impurity residual exist, the problem of non uniform gumming caused by the residual of the surface of the coating roller is avoided, a gap between a belt rubber roller and a glue roller is adjusted, the film thickness of the glue roller is well controlled, the film thickness on the two sides must be uniform, the roller speed ratio is well adjusted, and uniform gumming is guaranteed.

Owner:安徽墙煌科技股份有限公司

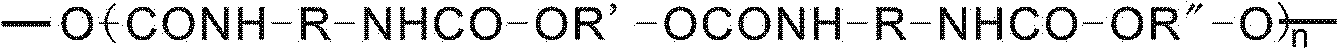

Highly scratch-resistant imprint material containing urethane compound

InactiveCN103329246AAvoid damageForming accuratelyNanoinformaticsSolid-state devicesCarbamateEthylene oxide

[Problem] To provide an imprint material capable of forming a film which exhibits high scratch resistance even after a pattern has been transferred thereto, specifically, an imprint material capable of forming a film such that, when the film is patterned by transferring and then subjected to a steel wool scratch test, few scratch marks are observed. [Solution] An imprint material which comprises (A) a compound that has at least one ethylene oxide unit and at least one polymerizable group, (B) a urethane compound that has at least one long-chain alkyl group having 13 to 25 carbon atoms and at least one polymerizable group and that is modified with polycaprolactone, and (C) a photopolymerization initiator.

Owner:NISSAN CHEM IND LTD

A method of film thickness control

ActiveCN113333243BControlling Bond StrengthSolve the problem of uneven bonding that is prone to occurMaterial gluingPretreated surfacesPolymer scienceBonding process

A method for controlling the thickness of an adhesive film, comprising using an adhesive film thickness control device, comprising the following steps: first selecting a suitable thickness difference die plate; on the surface of the film thickness control device and the connected upper connecting plate and lower connecting plate in order to lay polytetrafluoroethylene cloth, isolation film and air felt, wrap them as a whole and put them into a vacuum bag, and then together with Put the vacuum bag together into the autoclave, then complete the bonding and curing of the upper connecting plate and the lower connecting plate in the autoclave, and take out the glued parts to make the connection between the upper connecting plate and the lower connecting plate The thickness of the adhesive film is the target thickness of the adhesive film. The invention can better control the thickness of the glue film in the bonding process of the composite materials, thereby effectively controlling the bonding strength of the connecting joints of the composite materials, and effectively solving the problem of uneven bonding of the composite materials that is easy to occur in the bonding process of the composite materials. question.

Owner:CENT SOUTH UNIV

Film transfer printing equipment, transfer printing plate assembly, and adsorption force control device for transfer printing equipment

ActiveCN104708897BGood optical performanceImprove adsorption capacityTransfer printingSuction forceEngineering

The invention provides film transfer equipment, a transfer plate assembly and a transfer equipment adsorption force control device. The film transfer equipment comprises a transfer plate used for transferring a film layer to a base plate for the film layer to be transferred, and a base station used for bearing the base plate. The film transfer equipment further comprises an adsorption force control unit, wherein the adsorption force control unit acts on at least one of the base plate and / or the transfer plate in the transferring process so as to increase the difference between first adsorption force of the base plate to film forming matter transferred out from the transfer plate and second adsorption force generated by the transfer plate to the film forming matter. The film transfer equipment, the transfer plate assembly and the transfer equipment adsorption force control device can reduce residue and particle phenomena in the transferring and film forming processes through a simple and low-cost method.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

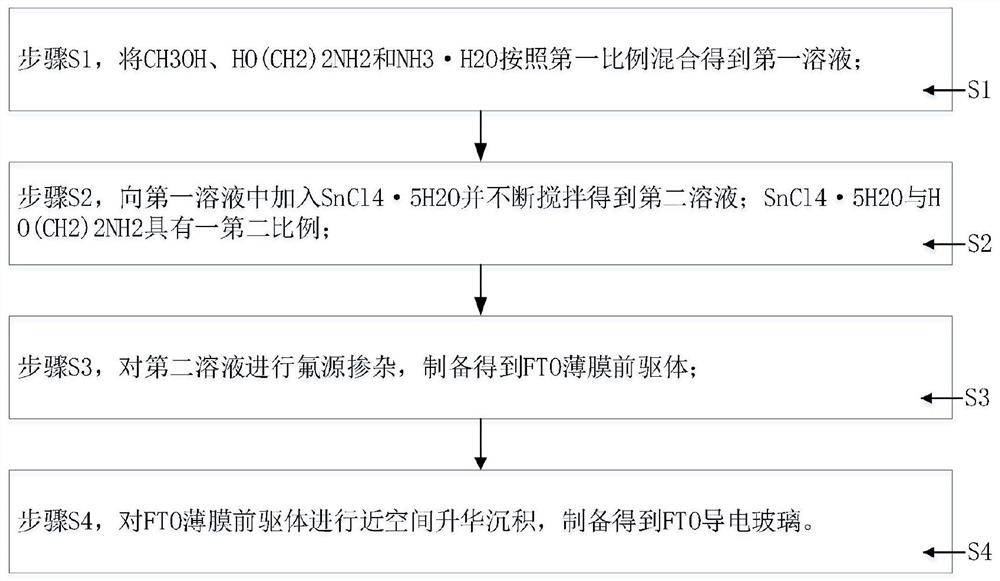

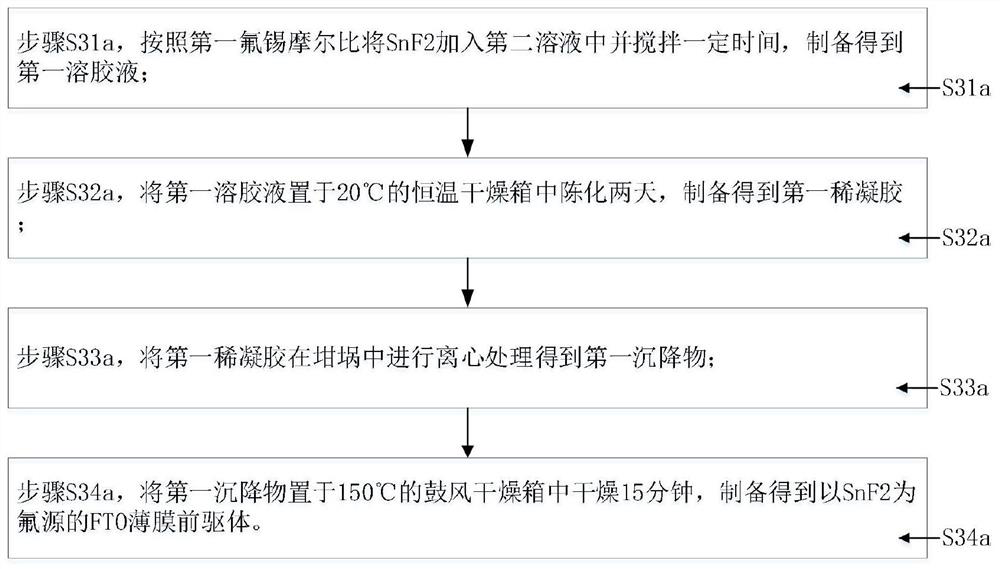

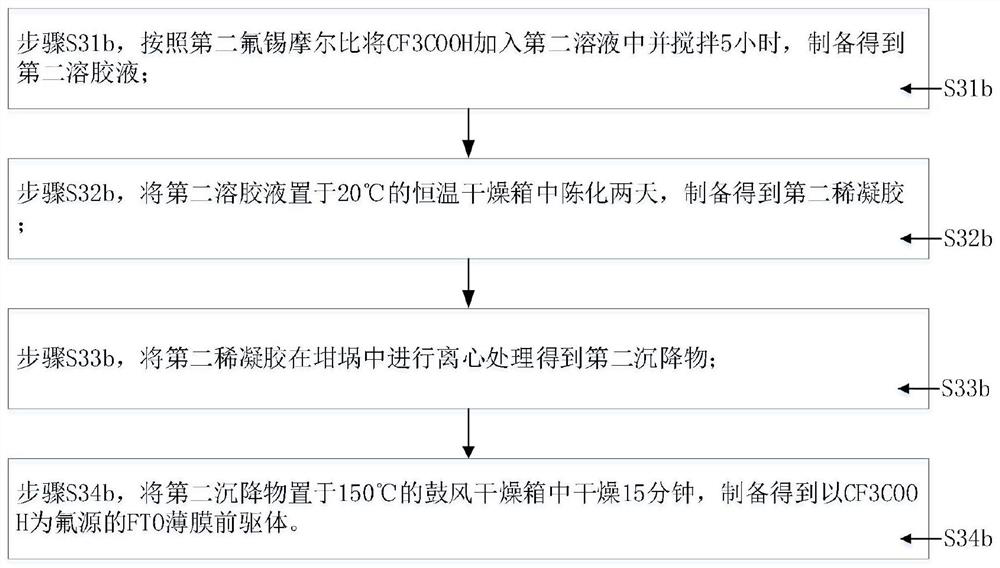

A method for preparing fto conductive glass by near space sublimation technology

The invention provides a method for preparing FTO conductive glass by using near space sublimation technology, and relates to the technical field of FTO conductive glass preparation, comprising: mixing CH3OH, HO(CH2)2NH2 and NH3·H2O according to a first ratio to obtain a first solution; Adding SnCl4·5H2O to the first solution and stirring continuously to obtain a second solution; the SnCl4·5H2O and the HO(CH2)2NH2 have a second ratio; doping the second solution with a fluorine source to prepare An FTO thin film precursor is obtained; the FTO thin film precursor is subjected to near-space sublimation deposition to prepare an FTO conductive glass. The invention has simple process and low cost, can use FTO precursor to control the composition of the FTO film layer, and is prepared in combination with the mature industrialized CSS process, and can obtain the FTO conductive glass with specific structure, morphology and photoelectric performance.

Owner:CHINA TRIUMPH INT ENG

Method of producing electronic component mounting structure, and electronic component mounting structure

InactiveCN102460667BControl film thicknessPorous dielectricsSemiconductor/solid-state device detailsFoaming agentLiquid state

Owner:PANASONIC CORP

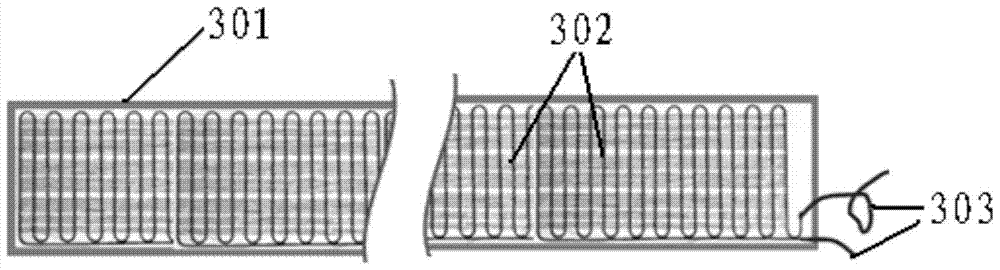

Film thickness control device and rapid film coating method thereof

PendingCN114107934AImprove stabilityUniform coatingVacuum evaporation coatingSputtering coatingElectric machineryComposite material

The invention discloses a film thickness control device and a rapid film plating method thereof, and relates to the technical field of lens film plating, in particular to a film thickness control device and a rapid film plating method thereof.The film thickness control device comprises a film plating machine shell, a driving motor is fixed to the upper surface of the film plating machine shell, and the output end of the driving motor is connected with a rotary disc; a rotary disc is arranged in the coating machine shell, a detection head is arranged in the rotary disc, a mounting plate is mounted in the coating machine shell, a material box is arranged at the front end of the mounting plate, baffles are arranged at the front end of the mounting plate and close to the two ends of the material box, and a fixing plate is arranged at the rear end of the mounting plate. According to the film thickness control device and the rapid film coating method thereof, the adjusting motor is arranged, the driving gear can be driven to rotate to be meshed with the toothed bar to move, the flow limiting cover is driven to move, the flow limiting cover moves to the position above the material box, evaporated gas is blocked, film coating on the lens is stopped, and the film thickness can be well controlled.

Owner:HUBEI HUAXIN PHOTOELECTRIC CO LTD

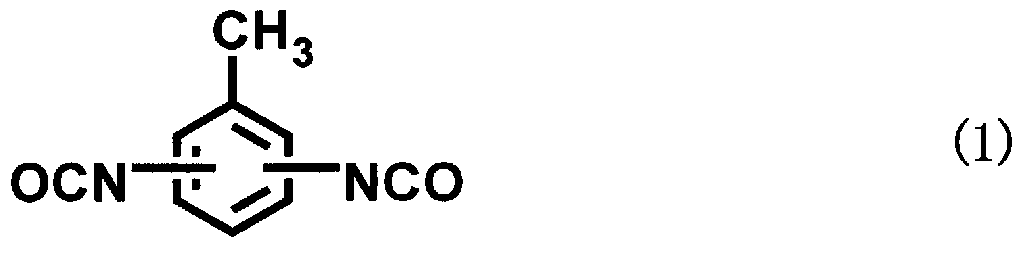

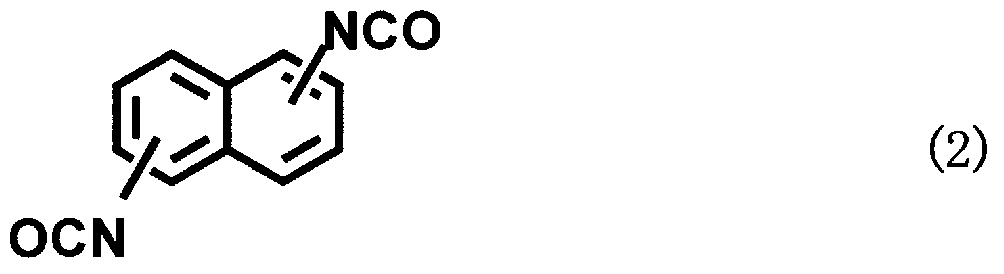

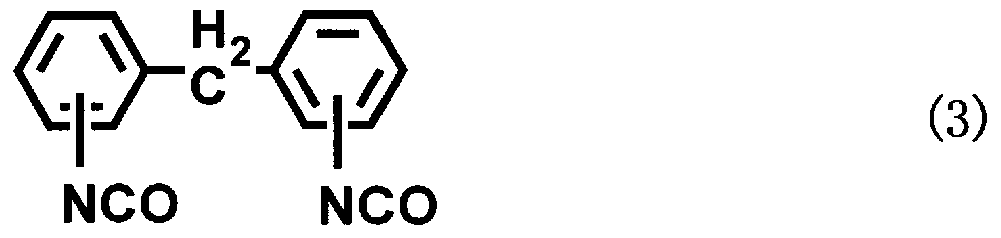

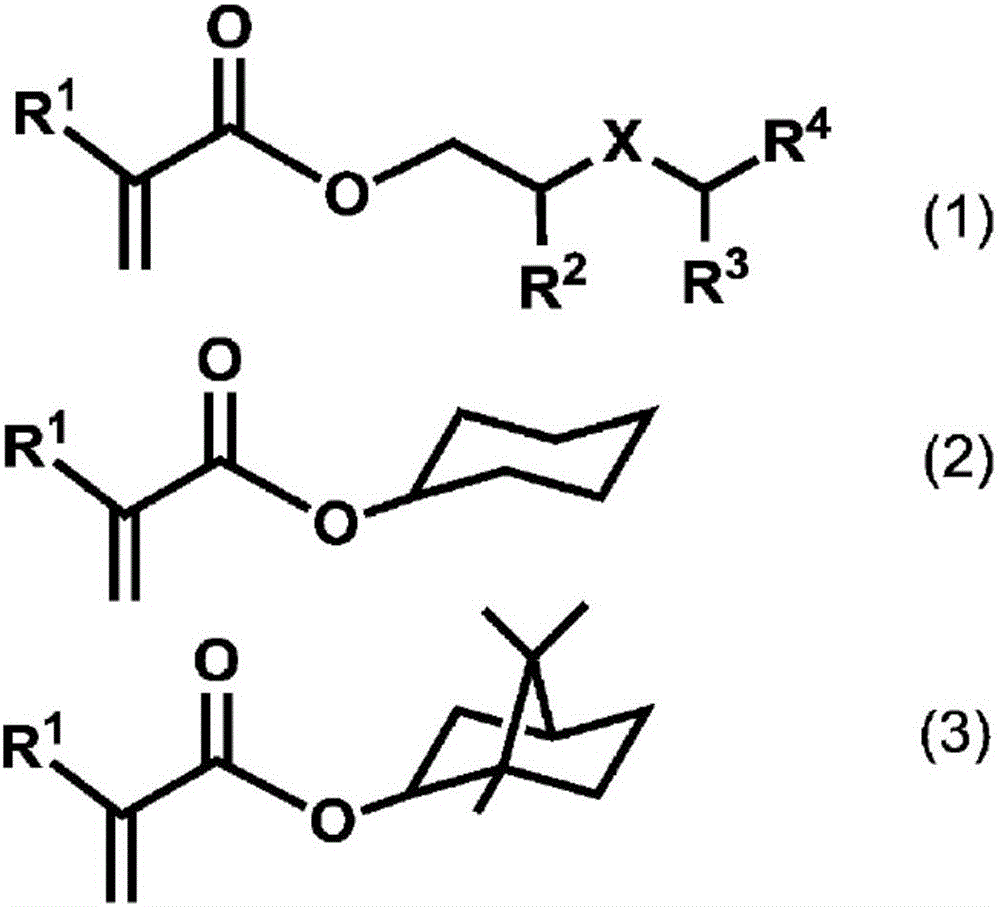

Imprinting material

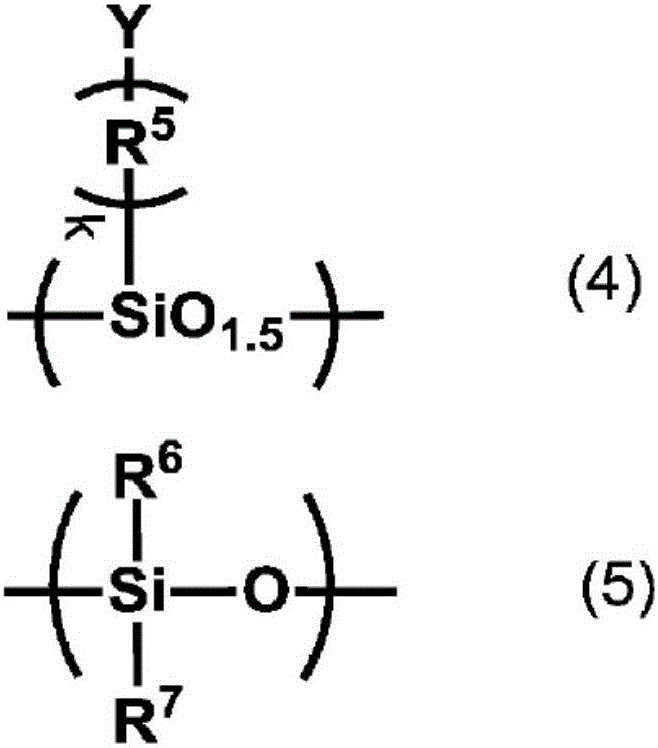

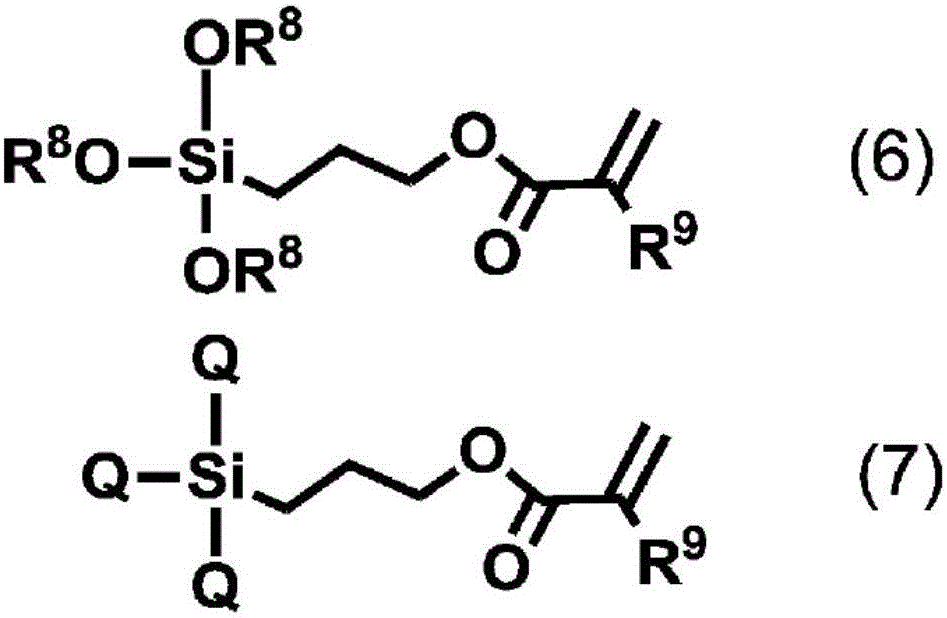

ActiveCN106575606ALow release forceLow plastic deformationPhotomechanical apparatusSemiconductor/solid-state device manufacturingEthyl groupSilsesquioxane

To provide a novel imprinting material and a film manufactured from said material and having a pattern transferred thereon. An imprinting material contains components (A), (B), (C), and (D) below. Component A is a compound represented by formula (1), (2), or (3) (wherein X is a 1-5 carbon atom straight-chain alkylene group, R1 is a hydrogen atom or methyl group, R2, R3, and R4 are each independently a hydrogen atom, methyl group, or ethyl group, and the sum of the number of carbon atoms in R2, R3, and R4 is 0-2.) Component B is a silsesquioxane compound having a repeating unit represented by formula (4) and having two or more polymerizable groups represented by Y in the formula. Component C is a silicone compound having a repeating unit represented by formula (5) and having two polymerizable groups at the terminal end thereof (wherein R6 and R7 are each independently a 1-3 carbon atom alkyl group, R5 is a 1-3 carbon atom alkylene group, and k is an integer of 0 to 3.) Component D is a photopolymerization initiator.

Owner:NISSAN CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com