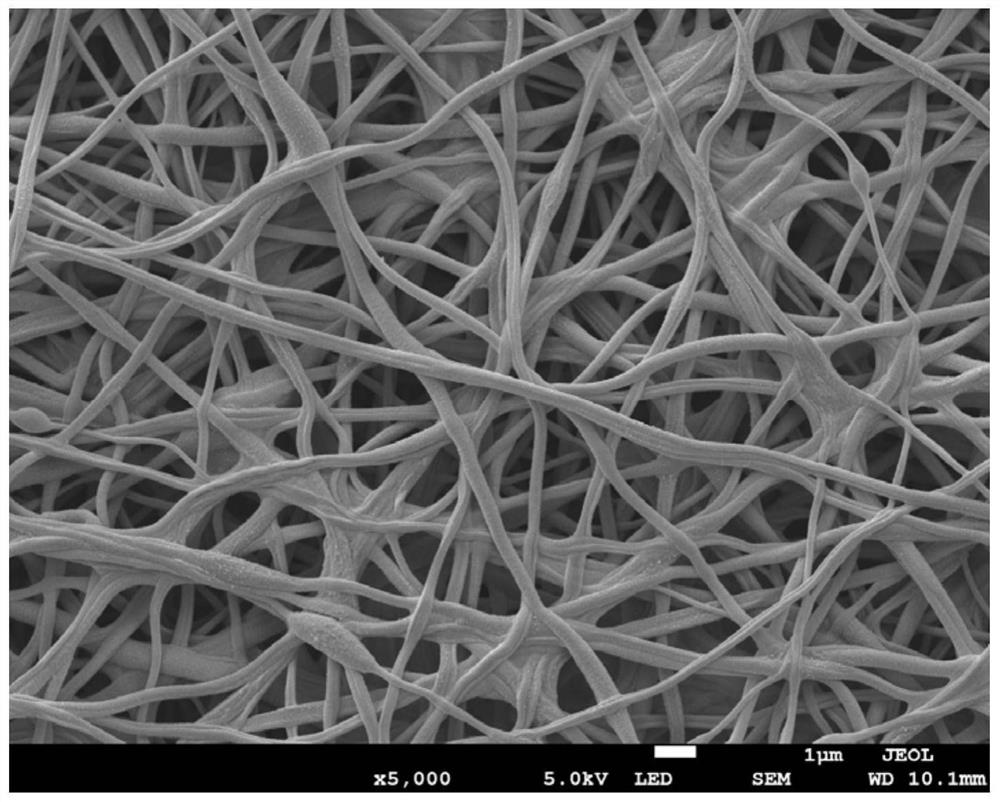

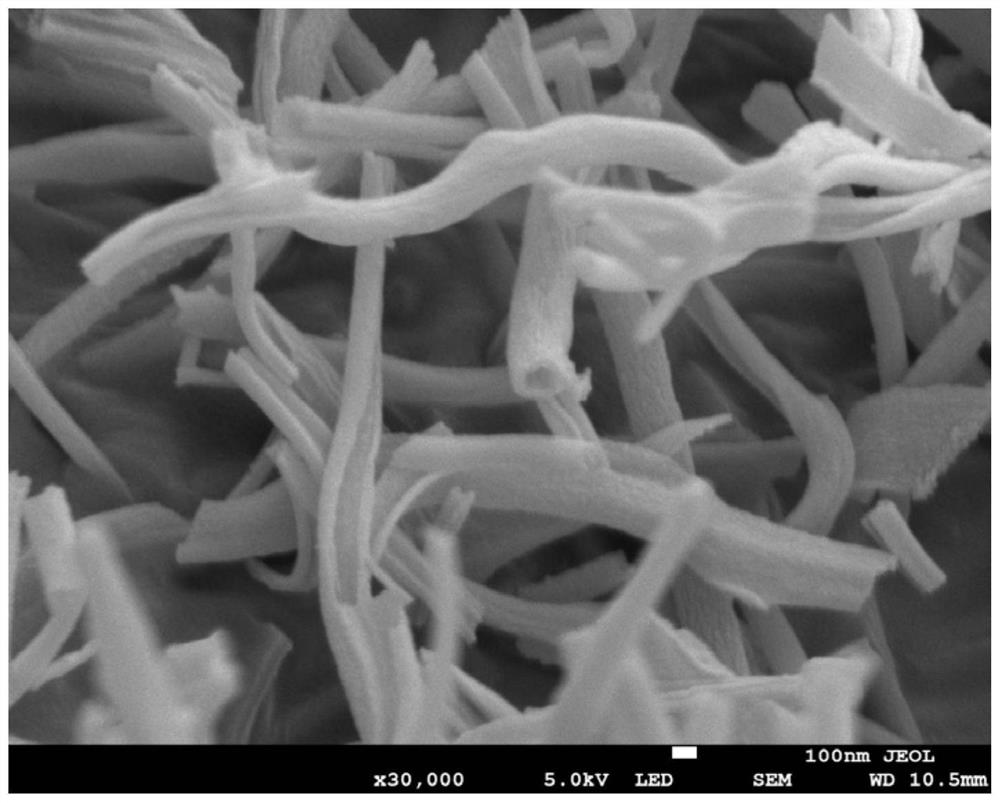

Ceramic fiber membrane, preparation method and application thereof

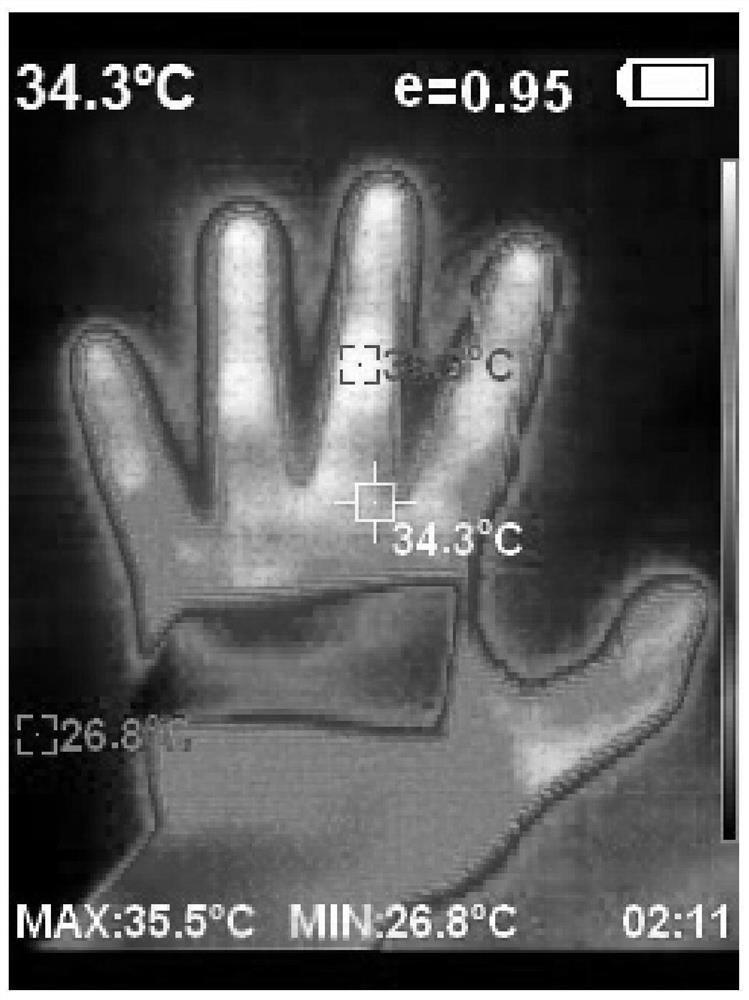

A technology of ceramic fiber and nano-ceramic fiber, which is applied in the direction of fiber chemical characteristics, textiles and papermaking, artificial filament of inorganic raw materials, etc., can solve the problem of difficulty in meeting the growing actual needs, poor electromagnetic wave shielding and infrared stealth effect, and acid resistance Alkali corrosion and high temperature oxidation and other problems, to achieve excellent infrared stealth effect, simple and reliable preparation method, effective absorption and shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of ceramic fiber membrane, its preparation method comprises the following steps:

[0054] 1) Stir and disperse 20 g of zirconium n-propoxide in 80 g of n-propanol, then add 5 g of acetic acid, then dropwise add 2 g of deionized water to carry out polycondensation reaction, and concentrate the solution to 50 g after reacting for 5 hours to obtain a ceramic precursor solution;

[0055] 2) Dispersing 10 g of polyacrylonitrile (number-average molecular weight of 150,000 g / mol) in 40 g of N,N-dimethylformamide to obtain a polyacrylonitrile solution;

[0056] 3) mixing the ceramic precursor solution and the polyacrylonitrile solution to obtain a spinning solution;

[0057] 4) Load the spinning solution into the syringe of the electrospinning machine, and use a 17G-22G coaxial needle for electrospinning. The outer layer of the coaxial needle is passed into the spinning solution, and the inner layer of the coaxial needle is passed into the mass fraction 3% N,N-dimethyl...

Embodiment 2

[0067] A kind of ceramic fiber membrane, its preparation method comprises the following steps:

[0068] 1) Stir and disperse 15g of zirconium n-propoxide and 5g of boric acid in 80g of n-propanol, then add 3g of acetic acid, then dropwise add 1.5g of deionized water for polycondensation reaction, and concentrate the solution to 50g after reacting for 5h , to obtain a ceramic precursor solution;

[0069] 2) Dispersing 10 g of novolac resin (number average molecular weight of 800 g / mol) in 40 g of N,N-dimethylformamide to obtain a phenolic resin solution;

[0070] 3) mixing the ceramic precursor solution and the phenolic resin solution to obtain a spinning solution;

[0071] 4) Load the spinning liquid into the syringe of the electrospinning machine, and use a 17G-25G coaxial needle for electrospinning. The outer layer of the coaxial needle is passed into the spinning liquid, and the inner layer of the coaxial needle is passed into the mass fraction 2% N,N-dimethylformamide so...

Embodiment 3

[0079] A kind of ceramic fiber membrane, its preparation method comprises the following steps:

[0080] 1) Stir and disperse 10 g of zirconium n-propoxide in 40 g of n-propanol, then add 3 g of acetylacetone, then dropwise add 1 g of deionized water for polycondensation reaction, and concentrate the solution to 25 g after reacting for 5 hours to obtain a ceramic precursor body solution I;

[0081] 2) Disperse 5g of polycarbosilane (number average molecular weight 1100g / mol, SALIFE) in 20g of toluene to obtain ceramic precursor solution II;

[0082] 3) Disperse 10 g of polyimide (number-average molecular weight of 3300 g / mol) in 40 g of N,N-dimethylformamide to obtain a polyimide solution;

[0083] 4) mixing ceramic precursor solution I, ceramic precursor solution II and polyimide solution to obtain spinning solution;

[0084] 5) Load the spinning solution into the syringe of the electrospinning machine, and use a 14G-20G coaxial needle for electrospinning. The outer layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com