Highly abrasion-resistant imprint material

A technology of base material and polymeric group, applied in the field of imprinting materials, to achieve the effect of expanding the process margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

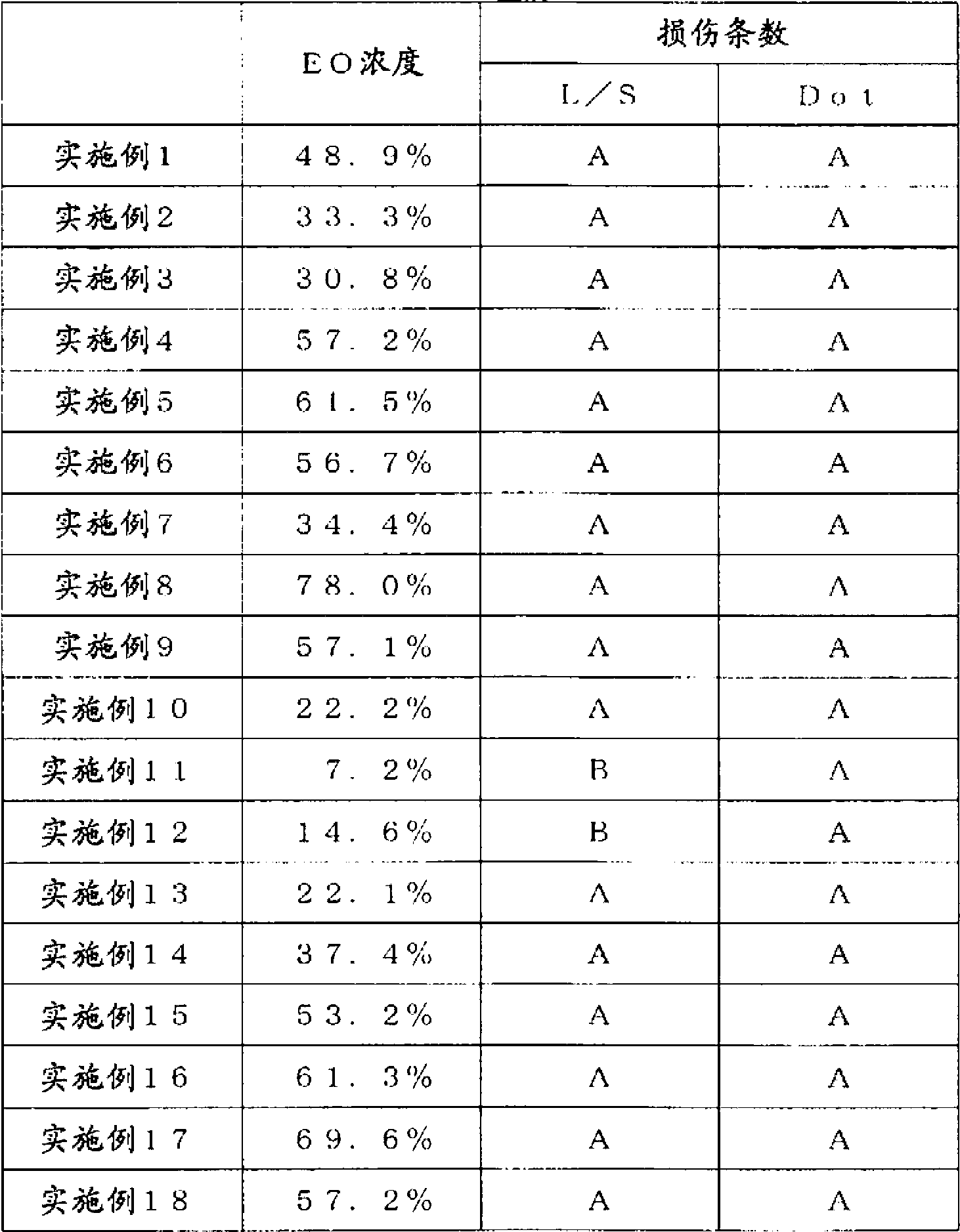

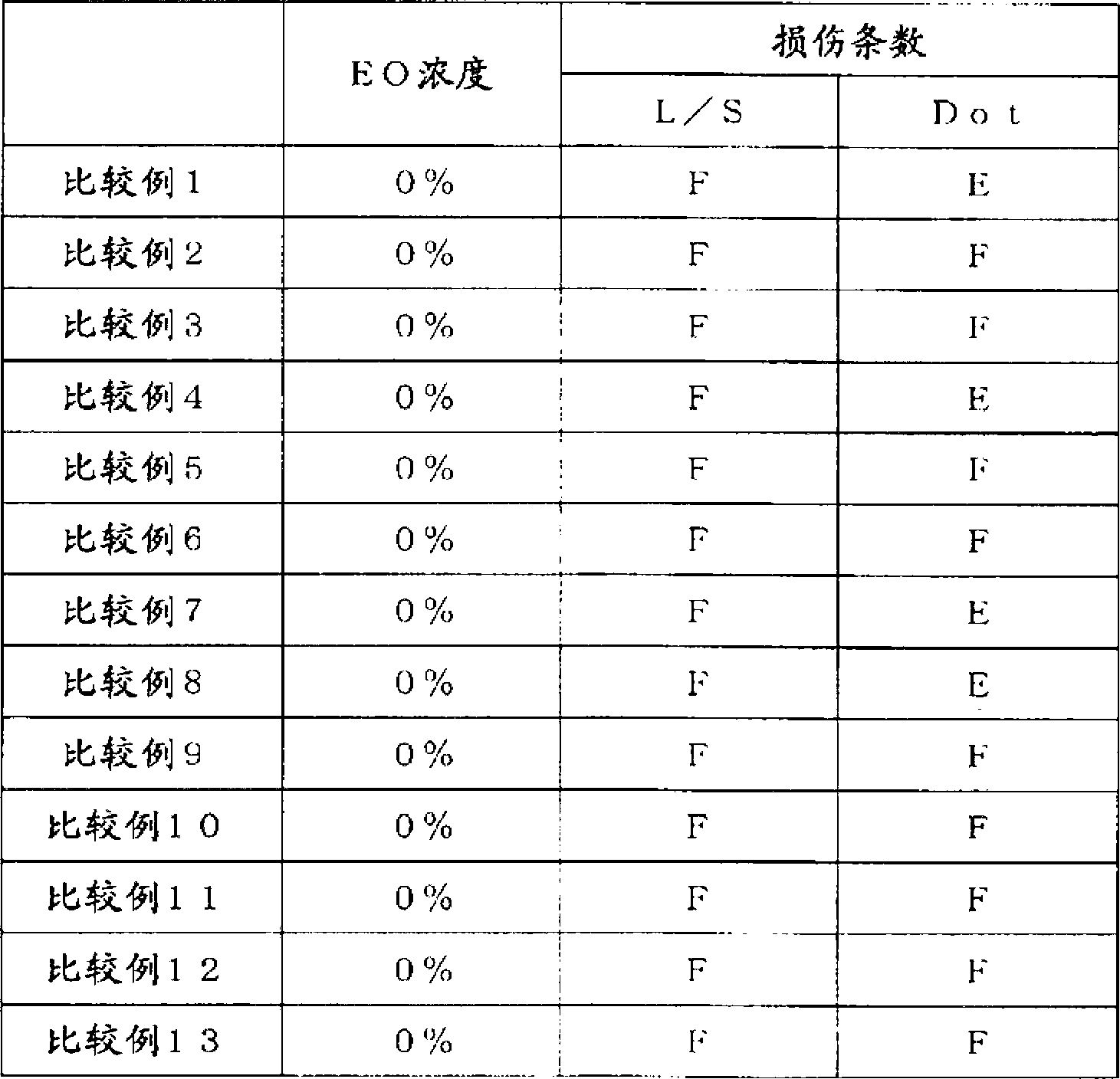

Examples

Embodiment

[0073] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated in detail, this invention is not limited to these Examples.

[0074] [Preparation of coating solution for film formation]

[0075]

[0076] DAROCUR (registered trademark) 1173 (BASF Japan Co., Ltd. Co., Ltd.) (hereinafter, abbreviated as “DAROCUR1173” in this specification.) 1 g (20 phr relative to the total mass of DPEA-12), and an imprint material PNI-A1 was prepared. In the present example, DPEA-12 corresponds to the component (A), and the number of oxyalkylene units per molecule is 12 EO (ethylene oxide units). DAROCUR1173 corresponds to (B) component.

Embodiment 2

[0078] DPEA-12 of Example 1 was changed to NK Ester ATM-4E (manufactured by Shin Nakamura Chemical Industry Co., Ltd., molecular weight: 529) (hereinafter, abbreviated as "ATM-4E" in this specification.), in addition, the same as In the same manner as in Example 1, an imprint material PNI-A2 was prepared. In the present example, ATM-4E corresponds to the component (A), and the number of oxyalkylene units per molecule is four EO.

Embodiment 3

[0080] DPEA-12 of Example 1 was changed to NK Ester A-TMPT-3EO (manufactured by Shin Nakamura Chemical Industry Co., Ltd., molecular weight: 428) (hereinafter, abbreviated as "A-TMPT-3EO" in this specification.), except Otherwise, it carried out similarly to Example 1, and prepared the imprint material PNI-A3. In the present example, A-TMPT-3EO corresponds to the component (A), and the number of oxyalkylene units per molecule is three EO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com