Waterborne polyurethane film and preparation technology thereof

A water-based polyurethane and preparation technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of volatile organic compound emission restrictions and achieve the effect of no VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

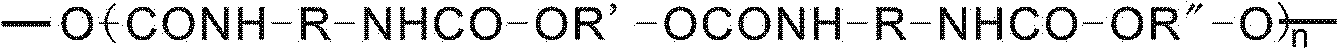

Method used

Image

Examples

Embodiment 1

[0029] Take 100g of water-based polyurethane emulsion JSJ-3090 (Guangzhou Leifu Technology Co., Ltd.), add thickener ASE60 (Rohm Haas company) 1g, disperse at high speed (rotating speed 800 rpm), and then add dropwise ammonia water 0.15g to The viscosity of the waterborne polyurethane coating is 20000mPa.s, and its solid content is 50wt%. Use a glass rod to scrape the water-based polyurethane coating on the release paper of the base material, drag the base material, so that the water-based polyurethane coating passes through a knife-edge gap, apply a thickness of 80 μm, dry at 60°C for 4 minutes, form a film, and wind up.

[0030] After testing, its tensile strength is 18-20Mpa, its elongation at break is 280-300%, and its water vapor transmission rate is 1200g / m 2 .24h.

Embodiment 2

[0032] Take 100 g of water-based polyurethane emulsion JSJ-3096 (Guangzhou Leifu Technology Co., Ltd.), add 2 g of thickener ASE60 (Rohm Haas Company), disperse at high speed (rotating speed 2400 rpm), and then add 0.1 g of ammonia water dropwise under slow stirring to The viscosity of the waterborne polyurethane coating is 50000mPa.s, and its solid content is 40wt%. Use a glass rod to scrape the water-based polyurethane coating on the substrate PET film, drag the substrate, so that the water-based polyurethane coating passes through a knife-edge gap, apply a thickness of 80 μm, dry at 80°C for 3 minutes, form a film, and wind up.

[0033] After testing, its tensile strength is 18-20Mpa, its elongation at break is 280-300%, and its water vapor transmission rate is 900g / m 2 .24h.

Embodiment 3

[0035] Take 100g of water-based polyurethane emulsion BAYDERM bottom 10UD (Lanxess Chemical (Shanghai) Co., Ltd.), add thickener TR-308 (Changzhou Sinoer Chemical Co., Ltd.) 2g, disperse at high speed (2400 rpm), and then stir slowly 0.15 g of triethylamine was added dropwise until the viscosity of the waterborne polyurethane coating was 30000 mPa.s, and its solid content was 28 wt%. Use a glass rod to scrape the water-based polyurethane coating on the substrate PET film, drag the substrate, so that the water-based polyurethane coating passes through a knife-edge gap, apply a thickness of 80 μm, dry at 40°C for 4 minutes, form a film, and wind up.

[0036] After testing, the tensile strength is 12-15Mpa, the elongation at break is 400-600%, and the water vapor transmission rate is 1500g / m2 .24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com