Lithium-rich manganese-based positive electrode material, and preparation method and use thereof

A lithium-rich manganese-based, cathode material technology, applied in chemical instruments and methods, battery electrodes, nickel compounds, etc., can solve the problems of high preparation cost, low battery capacity, complex preparation process, etc., to improve energy density and energy. The effect of density, flexibility and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

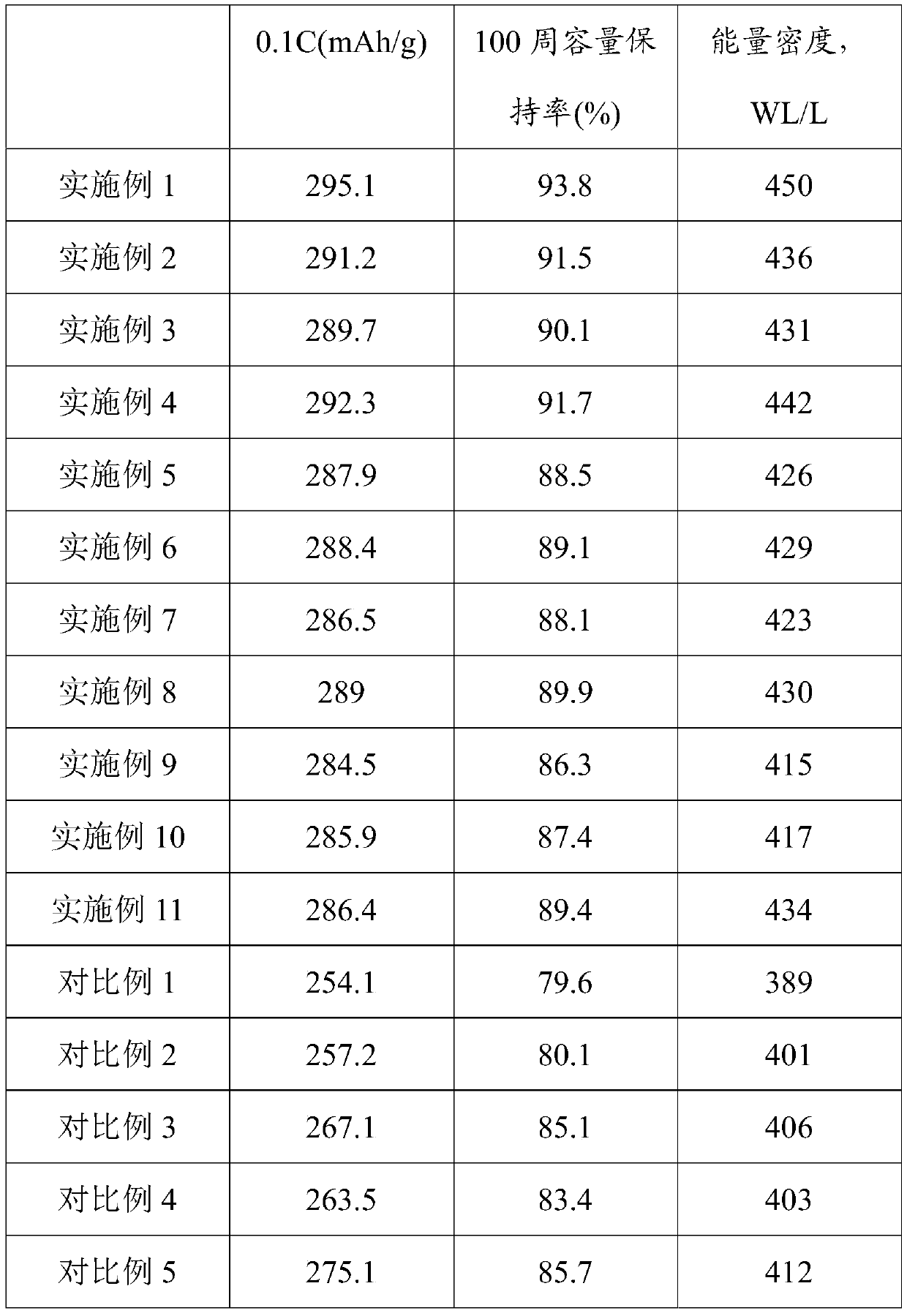

Examples

Embodiment 1

[0071] The molecular formula is Li 1.2 Mn 0.56 Ni 0.16 Co 0.08 O 2 The preparation method of the lithium-rich manganese-based cathode material includes the following steps:

[0072] (1') Prepare a mixed solution of nickel sulfate, manganese sulfate and cobalt sulfate with a total metal salt concentration of 2M, then add 2M sodium hydroxide solution, react at 55°C, add ammonia to adjust the pH of the reaction solution The manganese-based material was obtained by drying at 100°C for 12 hours; the molar ratio of nickel sulfate, manganese sulfate and cobalt sulfate was 0.2:0.7:0.1;

[0073] (2') Mix the manganese-based material obtained in step (1') with a lithium source, and perform two-step calcination, first calcining at 500°C for 6 hours, and then calcining at 850°C for 20 hours to obtain a lithium-rich manganese-based material intermediate; The lithium source is lithium carbonate, and its addition amount is 5 mol% more than its theoretical addition amount;

[0074] (3') Mix the lit...

Embodiment 2

[0077] The molecular formula is Li 1.2 Mn 0.64 Ni 0.08 Co 0.08 O 2 The preparation method of the lithium-rich manganese-based cathode material includes the following steps:

[0078] (1') Prepare a mixed solution of nickel chloride, manganese chloride and cobalt chloride with a total metal salt concentration of 2M, then add a sodium carbonate solution with a concentration of 1M, react at 55°C, and add ammonia to adjust the reaction solution The manganese-based material is obtained by drying at 100°C for 12 hours; the molar ratio of nickel chloride, manganese chloride and cobalt chloride is 0.1:0.8:0.1;

[0079] (2') Mix the manganese-based material obtained in step (1') with a lithium source, and perform two-step calcination, first calcining at 550°C for 6 hours, and then calcining at 950°C for 20 hours to obtain a lithium-rich manganese-based material intermediate; The lithium source is lithium carbonate, and its addition amount is 10 mol% more than its theoretical addition amount;...

Embodiment 3

[0083] The molecular formula is Li 1.2 Mn 0.32 Ni 0.32 Co 0.16 O 2 The preparation method of the lithium-rich manganese-based cathode material includes the following steps:

[0084] (1') Prepare a mixed solution of nickel nitrate, manganese nitrate and cobalt nitrate with a total metal salt concentration of 2M, then add a sodium carbonate solution with a concentration of 1M, react at 60℃, and add ammonia to adjust the pH of the reaction solution. 8. Drying at 100°C for 12 hours to obtain the manganese-based material; the molar ratio of nickel nitrate, manganese nitrate and cobalt nitrate is 0.4:0.4:0.2;

[0085] (2') Mix the manganese-based material obtained in step (1') with a lithium source, and perform two-step calcination, first calcining at 450°C for 6 hours, and then at 800°C for 20 hours to obtain a lithium-rich manganese-based material intermediate; The lithium source is LiOH, and its addition amount is 20 mol% more than its theoretical addition amount.

[0086] (3') Mix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com