ALD technology-based energy saving method for producing oxidation layer on medical device

A technology of medical devices and oxide layers, applied in coating, surgery, medical science, etc., can solve problems such as cracking, polymer drug-loaded layer shedding, human body skills, etc., to achieve change in adhesion and excellent large-area uniformity , to avoid the effect of shedding and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

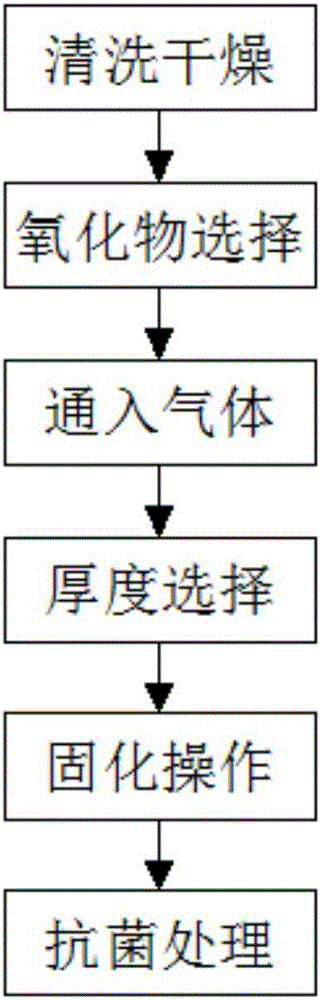

[0020] A method for preparing an oxide layer on a spinal internal fixator based on ALD technology,

[0021] Take out the internal fixator of the spine, remove the dust and oil stains attached to the surface, place it in the medical equipment cleaning and disinfection device, turn on the rotating motor and the cleaning nozzle to perform the rotation cleaning operation of the internal fixator of the spine, and then place it in the drying room after cleaning Carry out high-temperature drying and sterilization operations in the device, and take out the dried spinal internal fixer for use;

[0022] Select suitable alumina and silica for future use;

[0023] Use the dried and sterilized fixture to clamp the spinal internal fixer and put it into the operation cavity of ALD. At the same time, adjust the working temperature of the ALD deposition device to 100 ° C, adjust the flow rate of the carrier gas to 500 sccm, and evacuate the ALD studio, and Pass inert gas for cleaning operatio...

Embodiment 2

[0028] A method for preparing an oxide layer on an implantable alloy medical device based on ALD technology,

[0029] Similar to Example 1, the difference is that the working temperature, carrier gas flow and carrier gas pressure in the ALD deposition device can be adjusted, wherein the working temperature is set at 25-300 ° C, the carrier gas flow is set at 500-1000 sccm, and the inert The opening rate of the gas throttle valve can be increased to 50%, the probe voltage displayed by the oxygen detector is 920mV, and the temperature of the curing oven can be set at 200°C during the curing operation, and the curing time can be increased to 6h. During the treatment process, the mass ratio of titanate, hydrochloric acid, silver nitrate and zinc nitrate can be adjusted to 5%, 0.5%, 0.5% and 2.5%;

[0030]When preparing an oxide layer for implantable alloy medical devices, different from the oxidation operation for spinal internal fixers, 100-200 cyclic ALD deposition operations ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com