Hydrophobicity conductive tool coated with chromium carbide base metal ceramic electroplated layer and method for manufacturing same

A technology of coating chromium carbide and base metal, which is applied in the field of modification and application of hydrophobic conductive tools, can solve the problems of low density, poor corrosion resistance, deformation of substrates, etc., and achieve corrosion resistance and wear resistance , Improve electrical conductivity and corrosion resistance, high corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] In order to increase the service life of commonly used welding nozzles, hexavalent chromium hard chrome layer is often electroplated on its surface to make it have better surface hardness and conduct electricity; this embodiment uses chromium carbide-based cermet electroplating formed by electroplating The welding nozzle of the layer makes it have conductivity, hydrophobicity, good surface hardness and corrosion resistance. Please see Figure 8 , Figure 9 , Figure 12 ,and Figure 14 , Figure 8 It is a cross-sectional view of the horizontal electroplating layer; Figure 9 is the surface topography of the electroplating layer; Figure 12 It is the composition diagram of the electroplating layer (the ordinate is the angle between the energy intensity and the abscissa scanning range); Figure 14 is the contact angle diagram. The trivalent chromium electroplating solution adopted in this embodiment is a sulfate radical electroplating bath, and its composition and o...

Embodiment 2

[0079] Anti-static support plates can be used in electronic manufacturing production lines or explosives manufacturing production lines, which require high conductivity and corrosion resistance. Commonly used antistatic support plates are often made of metal, such as stainless steel or beryllium copper used in explosives production lines, but these materials have poor hydrophobicity and corrosion resistance. This embodiment is an antistatic support plate with a chromium carbide-based cermet plating layer formed by electroplating a tool base material made of glass, so that it has conductivity, hydrophobicity, good surface hardness and corrosion resistance. The trivalent chromium electroplating solution adopted in the present embodiment is a sulfate radical electroplating bath, and its composition and operating conditions are as shown in Table 4. The chromium carbide-based cermet electroplating layer formed by electroplating with this trivalent chromium electroplating solution an...

Embodiment 3

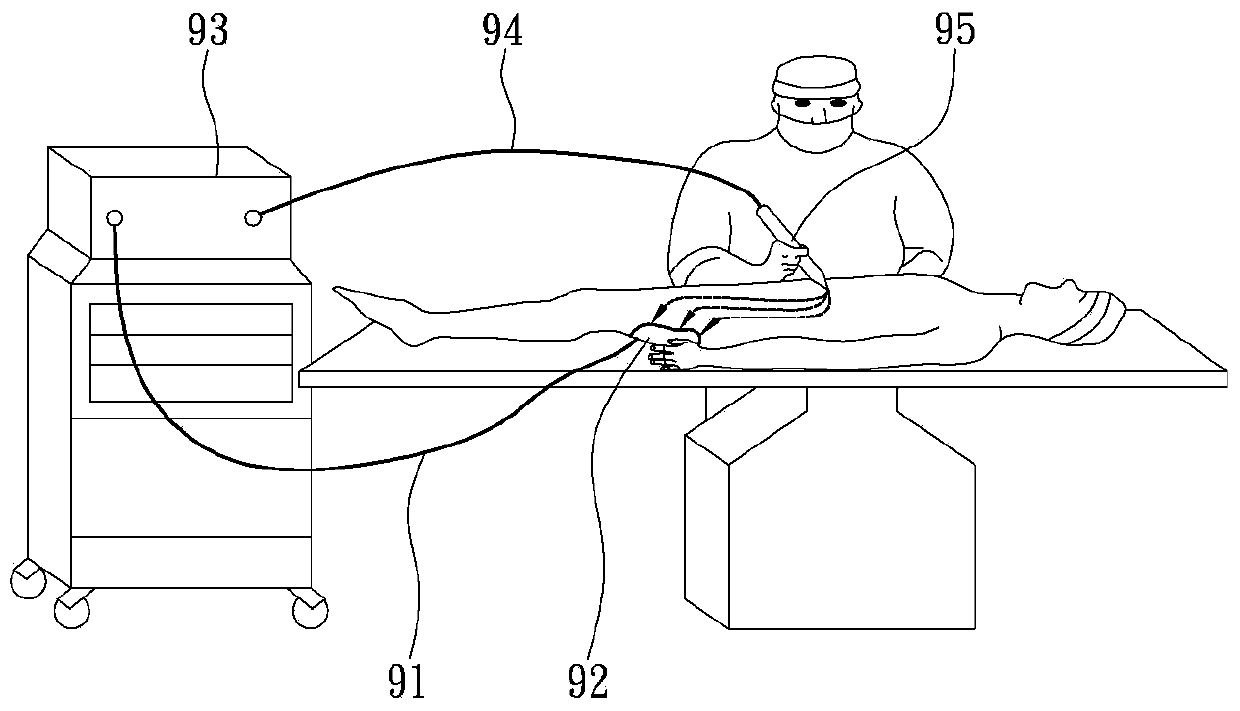

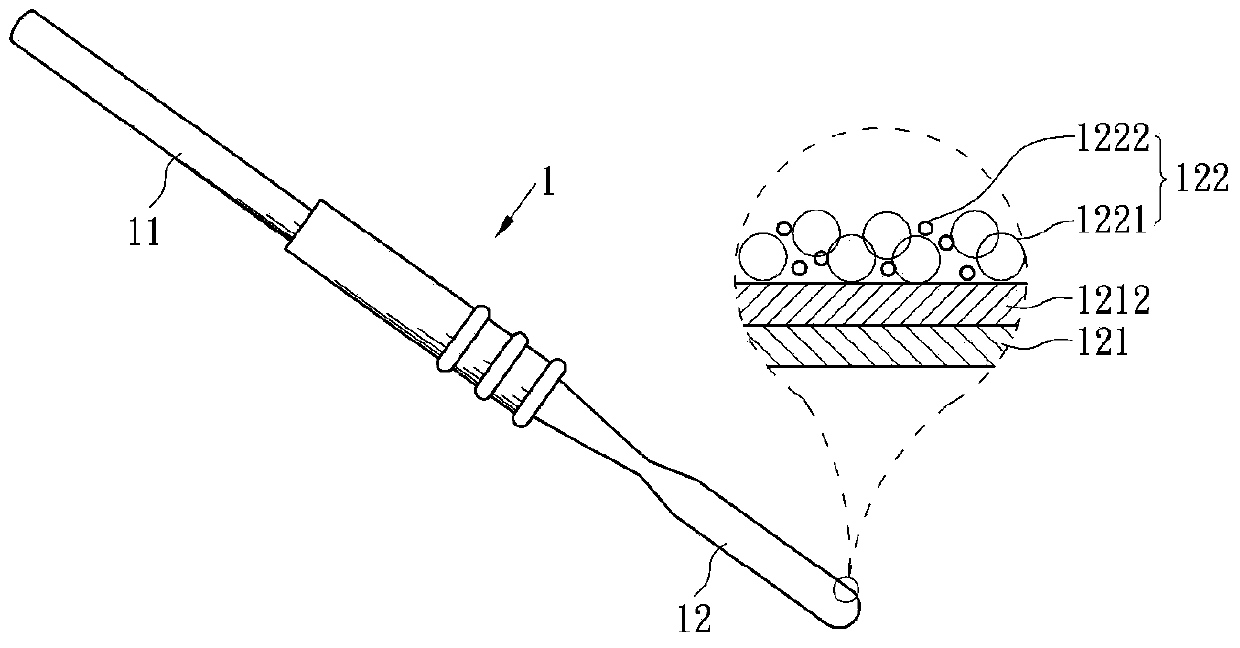

[0085] As mentioned above, the commonly used electrocautery scalpels are often coated with Teflon or chromium nitride film on the surface, because Teflon will release toxic gases containing fluorine, and the surface contact angle of chromium nitride film is 78°. Due to its hydrophilic nature, it is easy to cause sticking when cutting tissues; moreover, due to the poor conductivity of Teflon and chromium nitride films, there are restrictions on the use of electrocautery scalpels. refer to figure 2 , is the schematic diagram of the hydrophobic conductive tool of this embodiment used in medical surgical tools; among the figures, the surgical blade 12 is covered with a layer of chromium carbide-based cermet plating layer 122 on the tool substrate 121 by electroplating, and the chromium carbide-based cermet The composition analysis of electroplating layer 122 is as follows: Figure 5 , is a Cr-C structure in which the carbon element 1222 and the chromium element 1221 form an amor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com