Process for producing gan single-crystal, gan thin-film template substrate and gan single-crystal growing apparatus

A manufacturing method and template lining technology, which are applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of low thermal decomposition rate, etc., and achieve the effect of realizing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

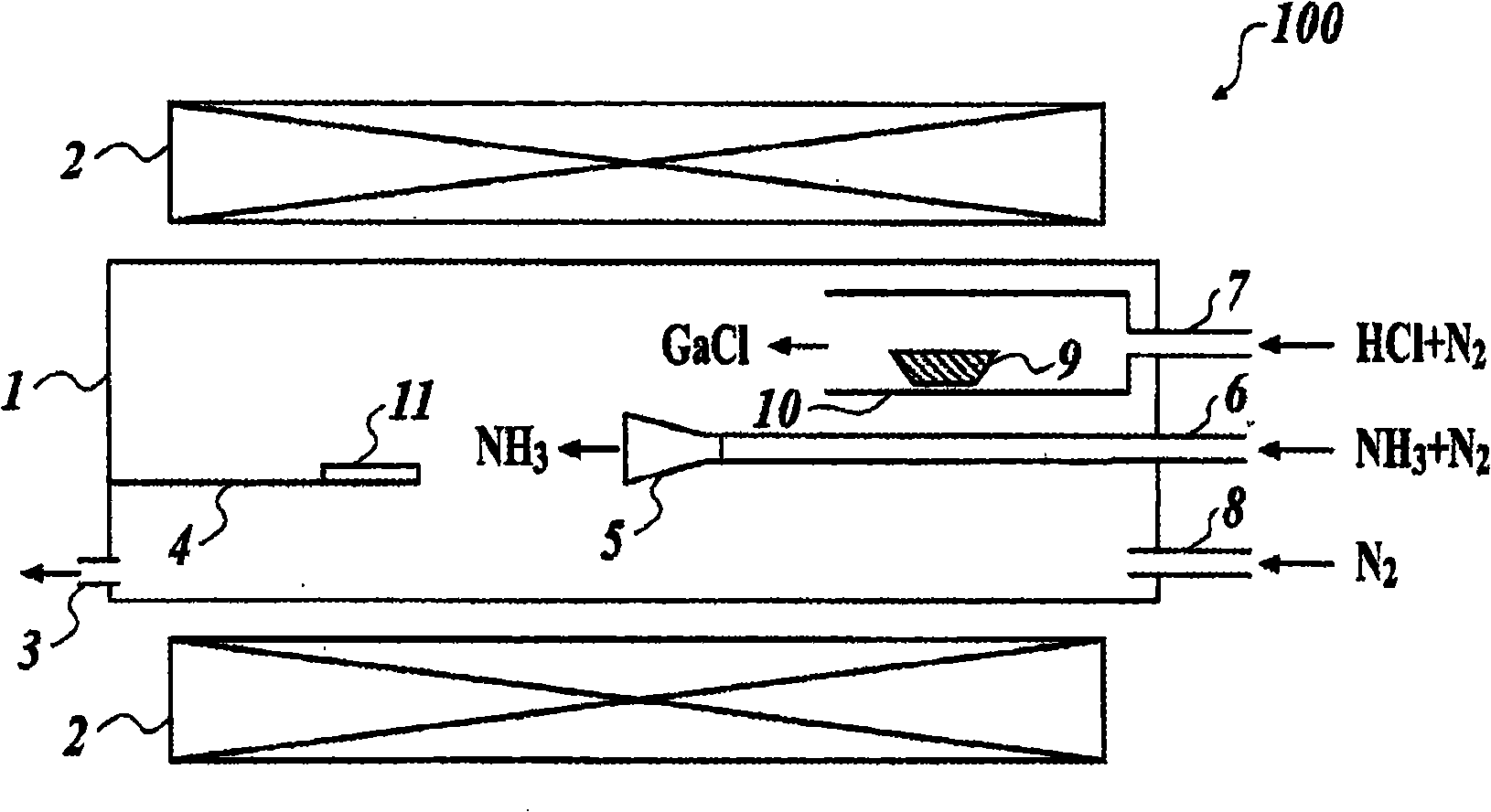

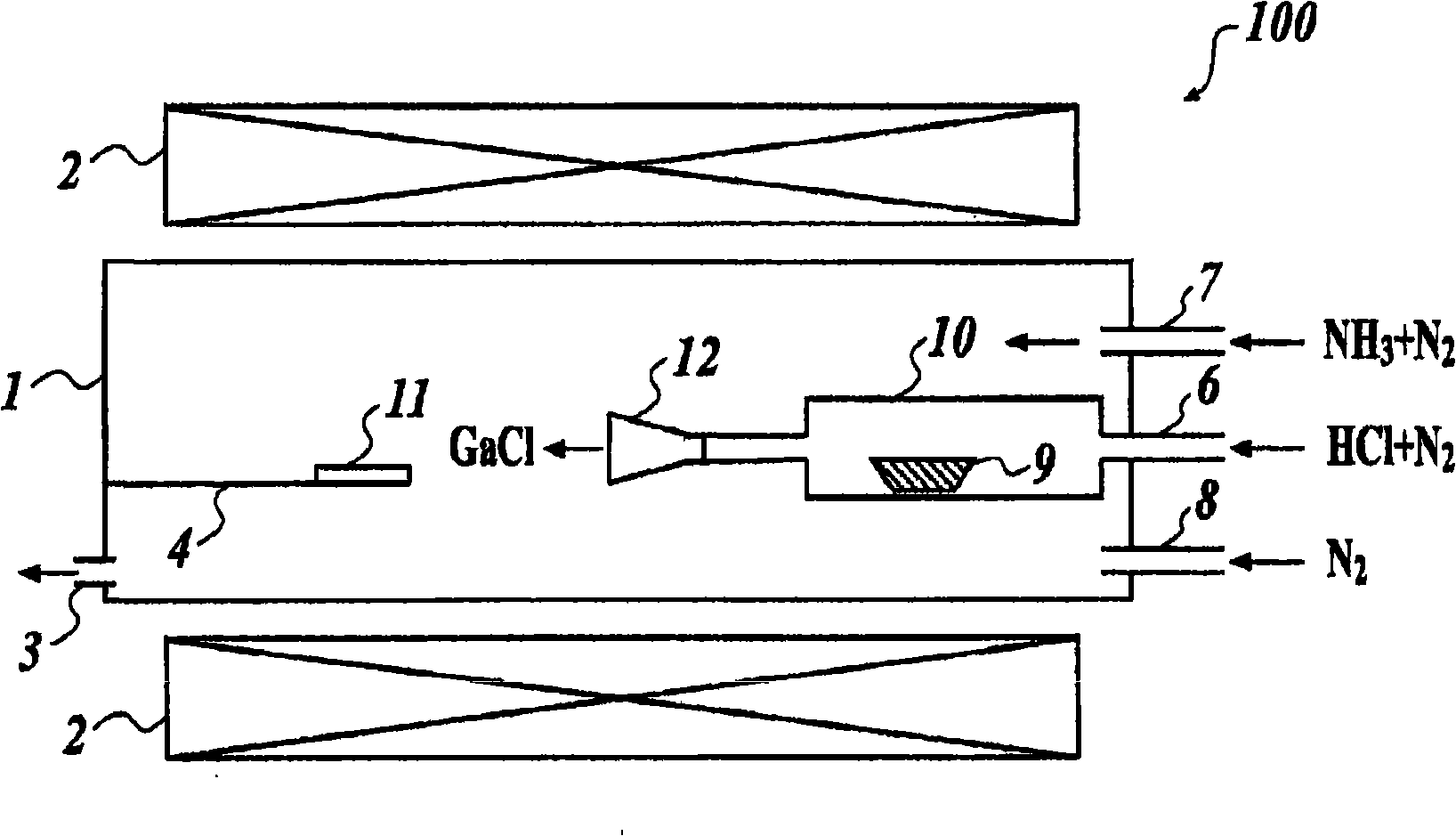

[0032] figure 1 It is a schematic diagram showing the structure of the vapor phase growth apparatus (HVPE apparatus) according to this embodiment.

[0033] The HVPE device 100 is composed of a sealed reaction furnace 1 and a resistance heating heater 2 provided on the outer periphery of the reaction furnace 1. The reaction furnace 1 is provided with an HCl gas supply pipe 7 for supplying HCl gas for generating group III raw material gas, and NH is supplied into the reaction furnace 3 Group V raw material gas supply pipe 6 for group V raw material gas such as gas, supplying N into the reactor 2 Gas N 2 The gas supply pipe 8, the gas exhaust pipe 3, and the substrate holder 4 on which the substrate 11 is placed.

[0034]A raw material mounting portion 10 is provided in the HCl gas supply pipe 6, and a metal raw material 9 for generating a group III raw material ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com