Preparation method of all-carbon composite film and product of all-carbon composite film

A carbon composite and product technology, which is applied in the field of preparation of all-carbon composite films, can solve problems such as poor bonding between film layers, and achieve the effects of reducing influence, simple steps and ensuring uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

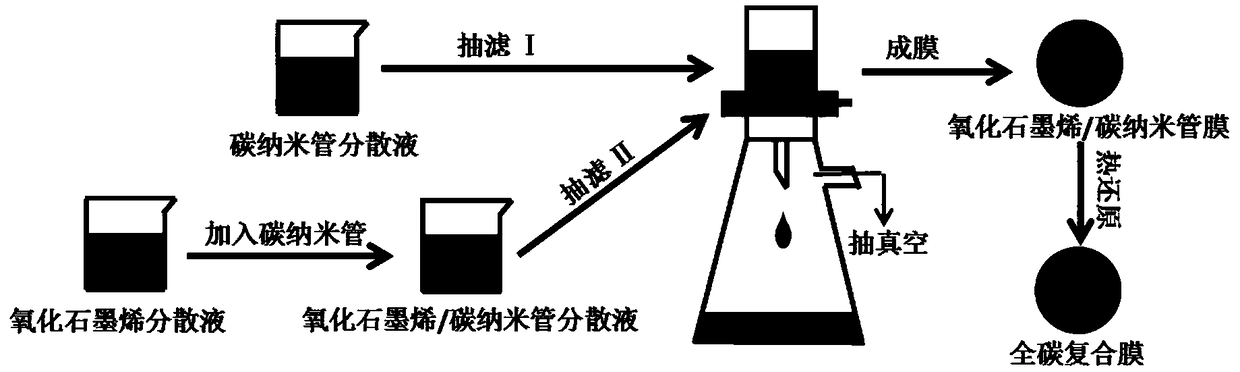

[0034] A method for preparing an all-carbon composite membrane, comprising the following steps:

[0035] (1) Ultrasonic treatment with a cell disruptor to obtain a carbon nanotube dispersion;

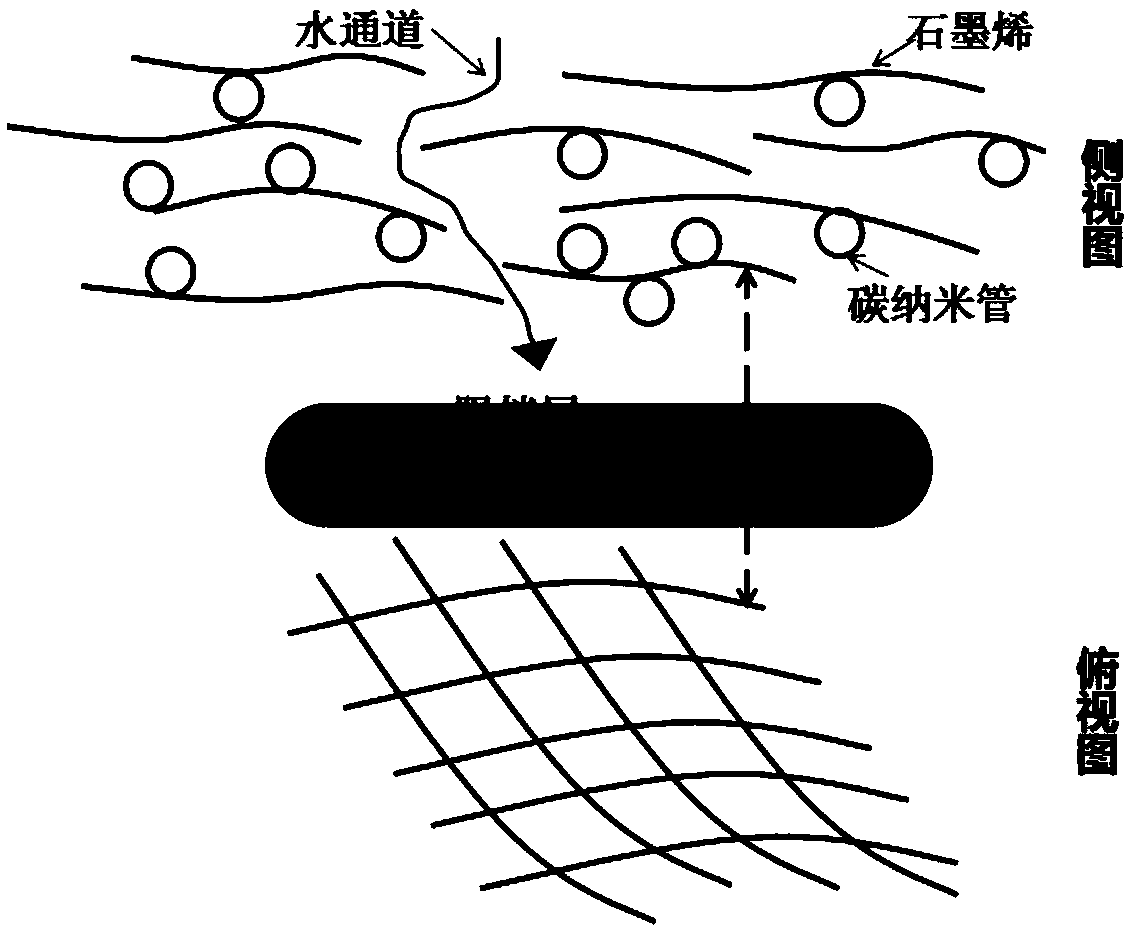

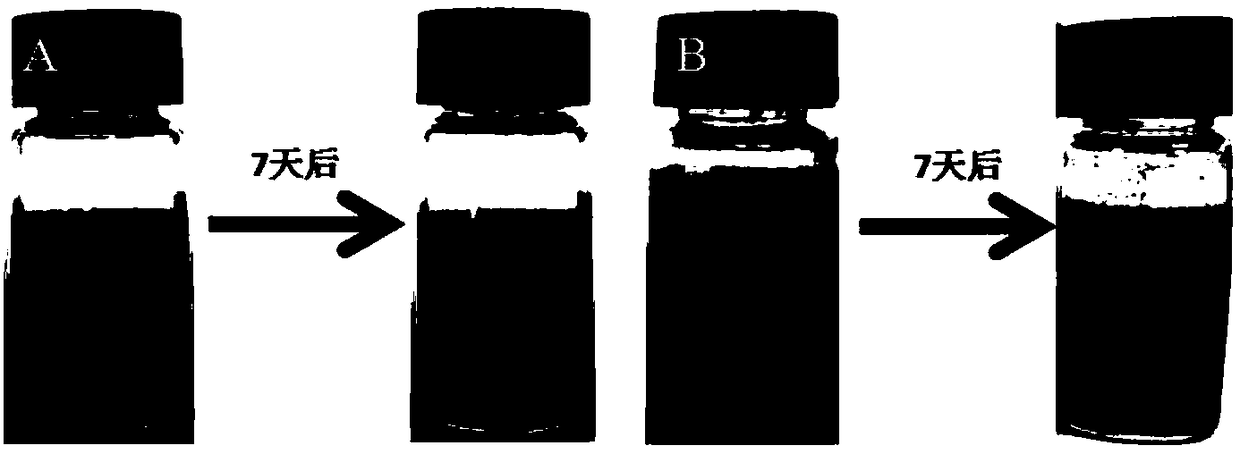

[0036] (2) Adopt the improved Hummers method to synthesize graphene oxide, this method is prior art, no longer exhaustive description at this, graphene oxide is formulated as the water dispersion of certain concentration; Then add the carbon nanotube of certain quality, make The mass ratio of carbon nanotubes to graphene oxide is 0 to 1, and a graphene oxide / carbon nanotube dispersion is obtained by ultrasonic treatment with a cell crusher;

[0037] (3) By suction filtration, the carbon nanotube dispersion prepared by a certain volume step (1) and the graphene oxide / carbon nanotube dispersion prepared by a certain volume step (2) are successively suction filtered, and then the prepared film is dried deal with;

[0038] (4) performing thermal reduction treatment on the composite film p...

Embodiment 1

[0047] (1) Ultrasonic treatment with a cell crusher was used to obtain a carbon nanotube dispersion. In the dispersion, 10 mg of carbon nanotubes and 100 ml of dispersant ethanol were used. The parameters were 400 W power, 60 min, and ice-water bath.

[0048] (2) Get 0.6mg graphene oxide to prepare dispersion liquid in 50ml deionized water; Add 0.4mg carbon nanotube then, make the mass ratio of carbon nanotube and graphene oxide be 0.67, graphene oxide and carbon nanotube dispersion concentration 0.02mg / ml; use a cell crusher to ultrasonically process the dispersion, the parameters are power 300W, time 30min, ice water bath;

[0049] (3) by suction filtration, successively suction filter the carbon nanotube dispersion prepared by step (1), the graphene oxide / carbon nanotube dispersion prepared by 20ml step (2), and then dry the prepared film;

[0050] (4) Heat the membrane prepared in step (3) to 300°C at a heating rate of 5°C / min in an argon / hydrogen (hydrogen 5%) atmosphere,...

Embodiment 2

[0053] (1) Ultrasonic treatment with a cell disruptor was used to obtain a carbon nanotube dispersion. In the dispersion, 10 mg of carbon nanotubes and 100 ml of ethanol were used. The parameters were 400 W power, 60 min, and an ice-water bath.

[0054] (2) Get 0.6mg graphene oxide to prepare dispersion liquid in 50ml deionized water; Then add 0.4mg carbon nanotube, make the mass ratio of carbon nanotube and graphene oxide be 0.67, graphene oxide / carbon nanotube dispersion concentration 0.02mg / ml; use a cell crusher to ultrasonically process the dispersion, the parameters are power 300W, time 30min, ice water bath;

[0055] (3) by suction filtration, successively suction filter the carbon nanotube dispersion prepared by (1), the graphene oxide / carbon nanotube dispersion prepared by 20ml step (2), and then dry the film prepared;

[0056] (4) Heat the membrane prepared in step (3) to 150°C at a heating rate of 1°C / min in an argon / hydrogen (hydrogen 5%) atmosphere, and keep it wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com