Method for preparing anhydrous proton exchange film based on sulfonated graphene oxide by utilizing spin-coating technology

A proton exchange membrane, sulfonated oxidation technology, used in final product manufacturing, electrochemical generators, sustainable manufacturing/processing, etc., to achieve the effect of improving proton conductivity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

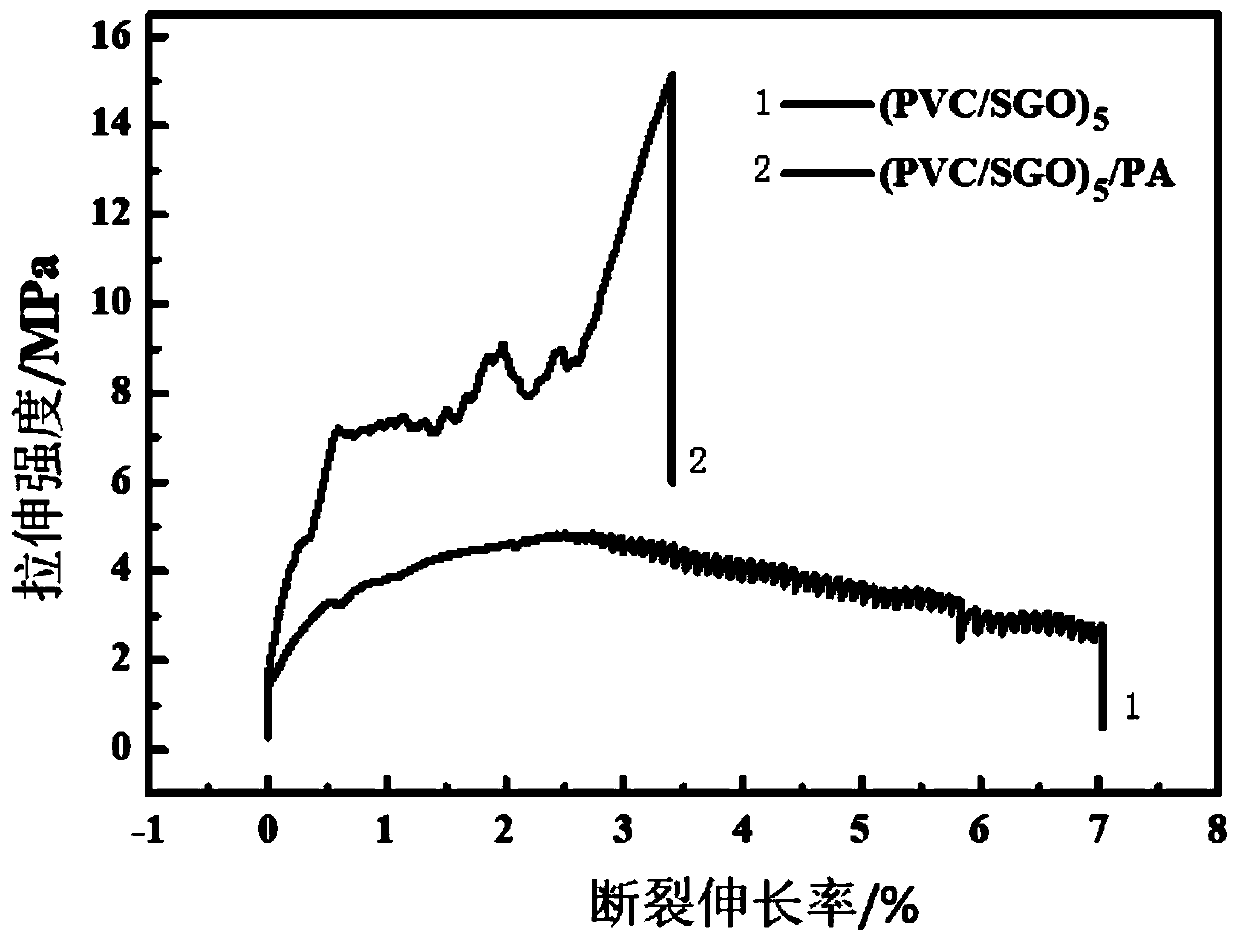

[0029] The preparation method of the phosphoric acid-doped spin-coated polymer composite film of this embodiment is carried out according to the following steps:

[0030] (1) 1.6g of polyvinyl chloride (PVC) was added to 20mL of N,N-dimethylformamide (DMF) to prepare a PVC solution with a mass fraction of 8%;

[0031] (2) 0.2g sulfonated graphene oxide (SGO) is added in the DMF of 20mL, is mixed with the SGO solution that mass fraction is 1%;

[0032] (3) Fix the glass substrate on the glue homogenizer, drop 2mL of PVC solution with a mass fraction of 8% on the glass plate with a pipette gun, spin coat at 1000rpm for 10 seconds, and bake in an oven at 80°C for 20 minutes;

[0033] (4) Use a pipette gun to take 1 mL of SGO solution with a mass fraction of 1% and drop it on a glass plate, bake it in an oven at 80°C for 20 minutes, and record it as (PVC / SGO) 1 spin-coated film;

[0034] (5) Steps (3)-(4) were repeated 5 times, the last layer was coated with PVC solution, and pl...

Embodiment 2

[0041] The preparation method of the phosphoric acid-doped spin-coated polymer composite film of this embodiment is carried out according to the following steps:

[0042] (1) 1.6g of polyvinyl chloride (PVC) was added to 20mL of N,N-dimethylformamide (DMF) to prepare a PVC solution with a mass fraction of 8%;

[0043] (2) 0.1g sulfonated graphene oxide (SGO) is added in the DMF of 20mL, is mixed with the SGO solution that mass fraction is 0.5%;

[0044] (3) Fix the glass substrate on the glue homogenizer, drop 2mL of PVC solution with a mass fraction of 8% on the glass plate with a pipette gun, spin coat at 1000rpm for 10 seconds, and bake in an oven at 80°C for 20 minutes;

[0045] (4) Use a pipette gun to take 1 mL of 0.5% SGO solution and drop it on a glass plate, bake it in an oven at 80°C for 20 minutes, and write it as (PVC / SGO) 1 spin-coated film;

[0046] (5) Steps (3)-(4) were repeated 5 times, the last layer was coated with PVC solution, and placed in an oven at 80...

Embodiment 3

[0051] The preparation method of the phosphoric acid-doped spin-coated polymer composite film of this embodiment is carried out according to the following steps:

[0052] (1) 1.6g of polyvinyl chloride (PVC) was added to 20mL of N,N-dimethylformamide (DMF) to prepare a PVC solution with a mass fraction of 8%;

[0053] (2) 0.2g sulfonated graphene oxide (SGO) is added in the DMF of 20mL, is mixed with the SGO solution that mass fraction is 1%;

[0054] (3) Fix the glass substrate on the glue homogenizer, drop 2mL of PVC solution with a mass fraction of 8% on the glass plate with a pipette gun, spin coat at 1000rpm for 10 seconds, and bake in an oven at 80°C for 20 minutes;

[0055] (4) Use a pipette gun to take 2 mL of SGO solution with a mass fraction of 1% and drop it on a glass plate, bake it in an oven at 80°C for 20 minutes, and record it as (PVC / SGO) 1 spin-coated film;

[0056] (5) Steps (3)-(4) were repeated 5 times, the last layer was coated with PVC solution, and pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com