Laminate manufacturing apparatus and laminate manufacturing method

A manufacturing method and laminated body technology, which is applied in lamination devices, semiconductor/solid-state device manufacturing, identification devices, etc., can solve problems such as damage, brittleness, and difficulty in peeling, and achieve the effect of uniform control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

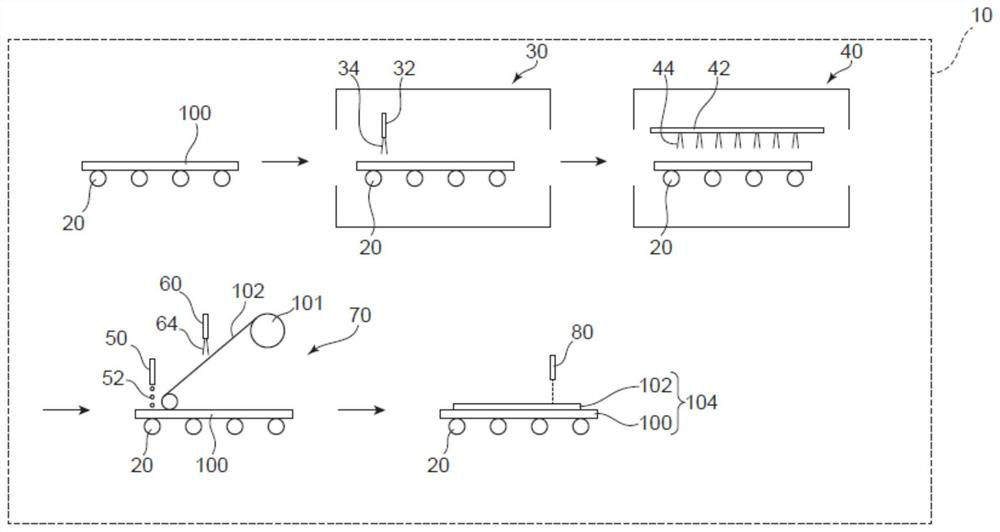

[0078] The laminate manufacturing apparatus according to the first embodiment has the following configuration.

[0079] (1) A laminate manufacturing device comprising:

[0080] An inorganic substrate transfer device for transferring inorganic substrates;

[0081] And a water supply device for supplying an aqueous medium to the surface of the inorganic substrate coated with the silane coupling agent, and / or the surface of the heat-resistant polymer film coated with the silane coupling agent;

[0082] And a laminating device for laminating the first sheet and the second sheet after supplying the aqueous medium.

[0083] (2) The laminated body manufacturing apparatus as described in (1) which has the coating apparatus which apply|coats a silane coupling agent to an inorganic board|substrate.

[0084] (3) The laminate manufacturing apparatus according to (1) or (2), comprising an inorganic substrate cleaning device for cleaning the inorganic substrate before supplying the aqueou...

no. 2 Embodiment approach

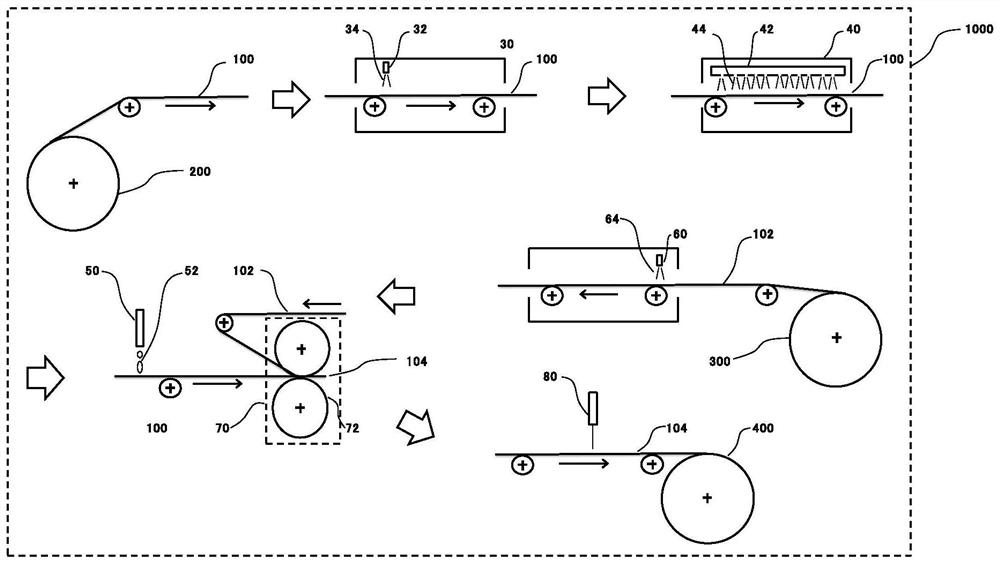

[0218] The laminate roll manufacturing apparatus according to the second embodiment has the following configuration.

[0219] (1) A laminated body roll manufacturing apparatus having:

[0220] Metal foil handling devices for handling metal foil;

[0221] And a water supply device for supplying an aqueous medium to the surface of the metal foil coated with the silane coupling agent, and / or the surface of the heat-resistant polymer film coated with the silane coupling agent;

[0222] And a roll lamination device that bonds metal foil and heat-resistant polymer film after one or both of them are supplied with an aqueous medium.

[0223] (2) The laminated body roll manufacturing apparatus as described in (1) which has the coating apparatus which apply|coats a silane coupling agent to metal foil.

[0224] (3) The laminated body roll manufacturing apparatus as described in (1) or (2), which has the metal foil washing|cleaning apparatus which washes the metal foil before supplying ...

no. 3 Embodiment approach

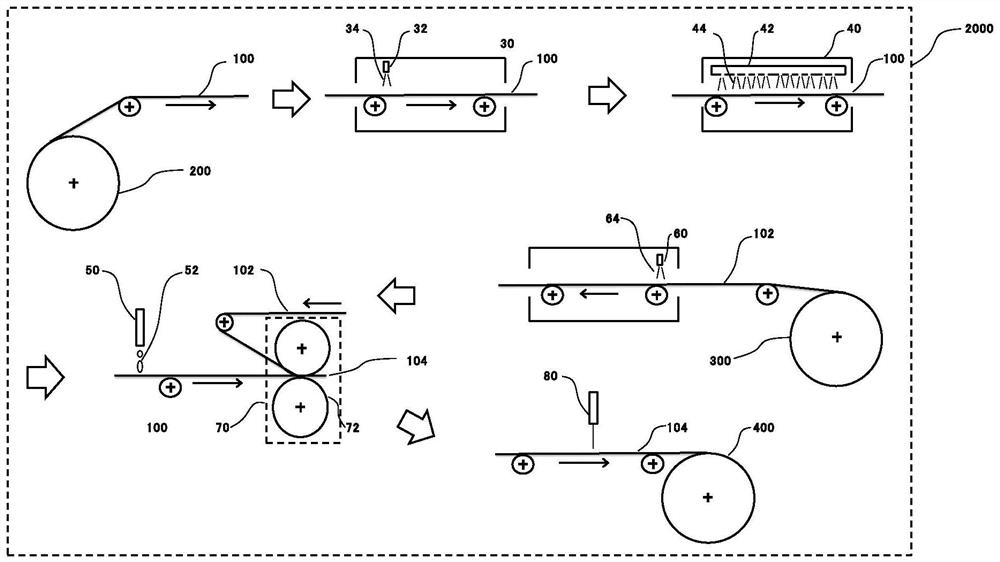

[0293] The heat-resistant polymer film laminate manufacturing apparatus according to the third embodiment has the following configuration.

[0294] (1) An apparatus for manufacturing a heat-resistant polymer film laminate, comprising:

[0295] A film transfer device for transferring the first heat-resistant polymer film;

[0296] And a water supply device for supplying an aqueous medium to the surface of the first heat-resistant polymer film coated with the silane coupling agent, and / or the surface of the second heat-resistant polymer film coated with the silane coupling agent;

[0297] After supplying an aqueous medium to one or both of the first heat-resistant polymer film and the second heat-resistant polymer film, the first heat-resistant polymer film and the second heat-resistant polymer film are laminated. laminating device.

[0298] (2) The apparatus for producing a heat-resistant polymer film laminate according to (1), comprising a coating device for applying a silan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com