Car room lens protective film and preparation method thereof

A protective film and lens technology, which is applied in the direction of pressure-sensitive film/sheet, film/sheet release liner, film/sheet-shaped adhesive, etc. It can solve the problems of complex manufacturing process, complex structure, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

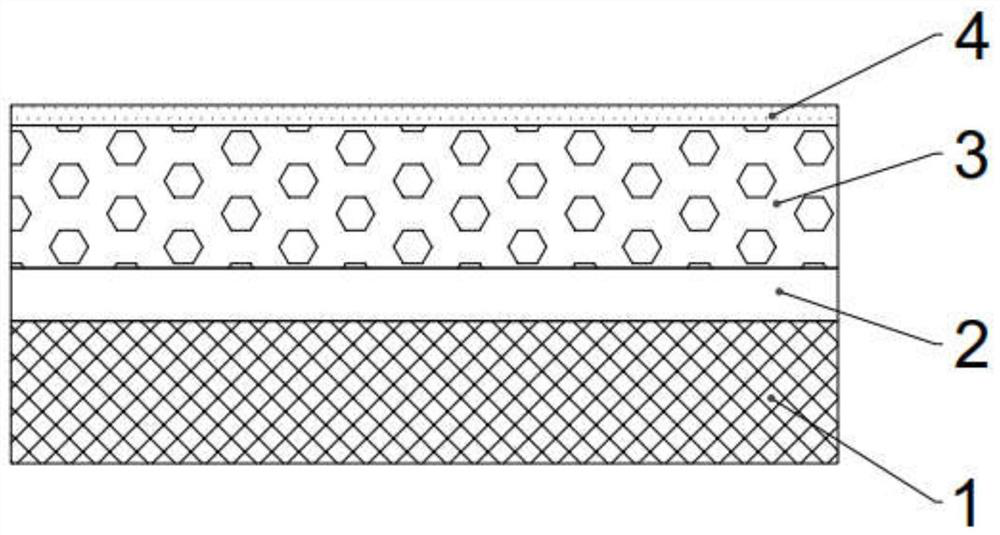

[0027] Such as figure 1 As shown, this embodiment provides a protective film for automotive lenses, which includes a double-sided release layer 1 , a pressure-sensitive adhesive layer 2 , a substrate layer 3 and an alloy adhesive layer 4 which are stacked in sequence.

[0028] The double-sided release layer 1 is a double-sided PET release paper. The pressure-sensitive adhesive layer 2 is an acrylic pressure-sensitive adhesive, the thickness of the pressure-sensitive adhesive layer 2 is 15 μm, and the peeling force is 350-450 gf / inch. The substrate layer 3 is a PE film, which is used to isolate the pressure-sensitive adhesive layer 2 and the alloy adhesive layer 4 to prevent the two layers from sticking to each other. The alloy bonding layer 4 is a water-based polyurethane coating with a thickness of 2 μm. The raw materials of the alloy bonding layer 4 include water-based polyurethane and a curing agent, and the amount of the curing agent added is 1%wt.

[0029] This embodim...

Embodiment 2

[0034] This embodiment provides a protective film for a garage lens, which includes a double-sided release layer, a pressure-sensitive adhesive layer, a base material layer, and an alloy adhesive layer that are stacked in sequence.

[0035] The double-sided release layer is double-sided release paper. The pressure-sensitive adhesive layer is an acrylic pressure-sensitive adhesive, the thickness of the pressure-sensitive adhesive layer is 18 μm, and the peeling force is 400-500 gf / inch. The substrate layer is PE film. The alloy bonding layer is a water-based polyurethane coating with a thickness of 1 μm. The raw materials of the alloy adhesive layer include water-based polyurethane and curing agent, and the amount of curing agent added is 0.3% wt.

[0036] The difference between the preparation method of the garage lens protective film in this embodiment and that in Embodiment 1 is that step S3 is coated with a micro concave roller, and the other parts are the same.

Embodiment 3

[0038] This embodiment provides a protective film for a garage lens, which includes a double-sided release layer, a pressure-sensitive adhesive layer, a base material layer, and an alloy adhesive layer that are stacked in sequence.

[0039] The double-sided release layer is double-sided release paper. The pressure-sensitive adhesive layer is a water-based acrylic pressure-sensitive adhesive, and the thickness of the pressure-sensitive adhesive layer is 20 μm. The substrate layer is PP film. The alloy bonding layer is a water-based polyurethane coating with a thickness of 2 μm. The raw materials of the alloy adhesive layer include water-based polyurethane and curing agent, and the amount of curing agent added is 0.3% wt.

[0040] The preparation method of the garage lens protective film in this embodiment is the same as that in Embodiment 1.

[0041] The invention can control the bonding strength by controlling the thickness of the alloy bonding layer, the penetration depth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com