Automatic iron plate surface physical rust removal equipment for large part machining

A technology for physical derusting and large-scale parts, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of complex operation and low efficiency of manual derusting, reduce labor intensity, and facilitate blanking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

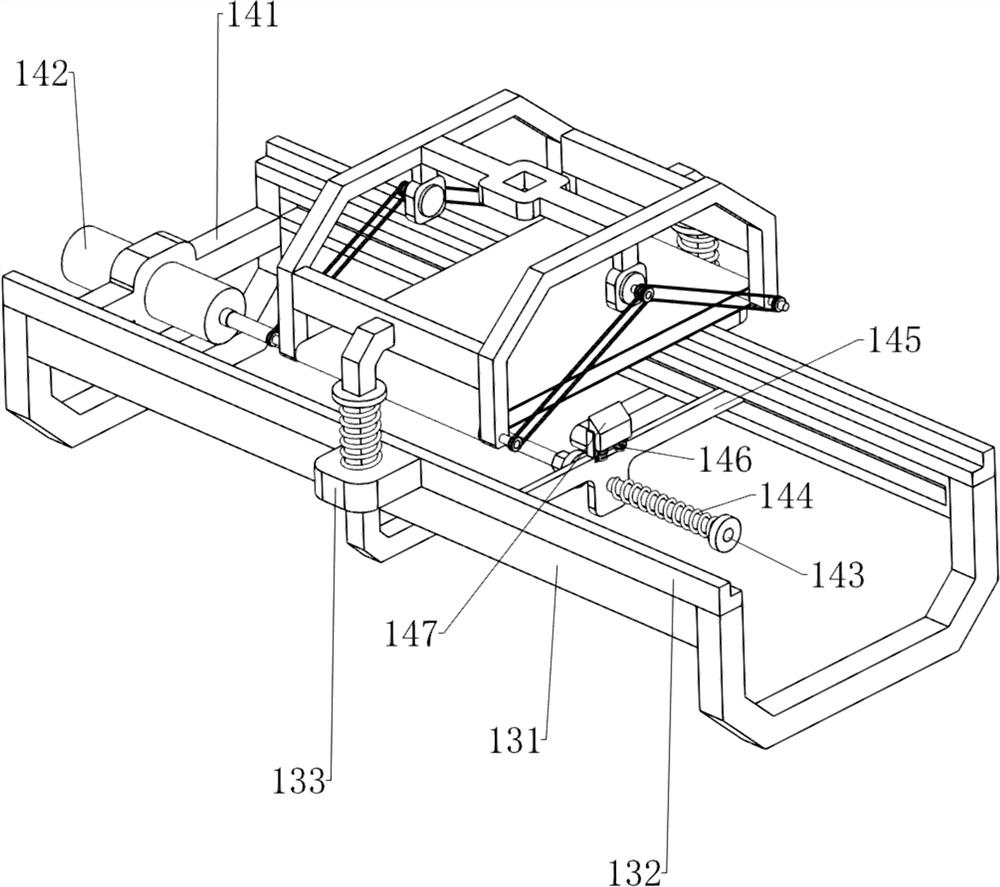

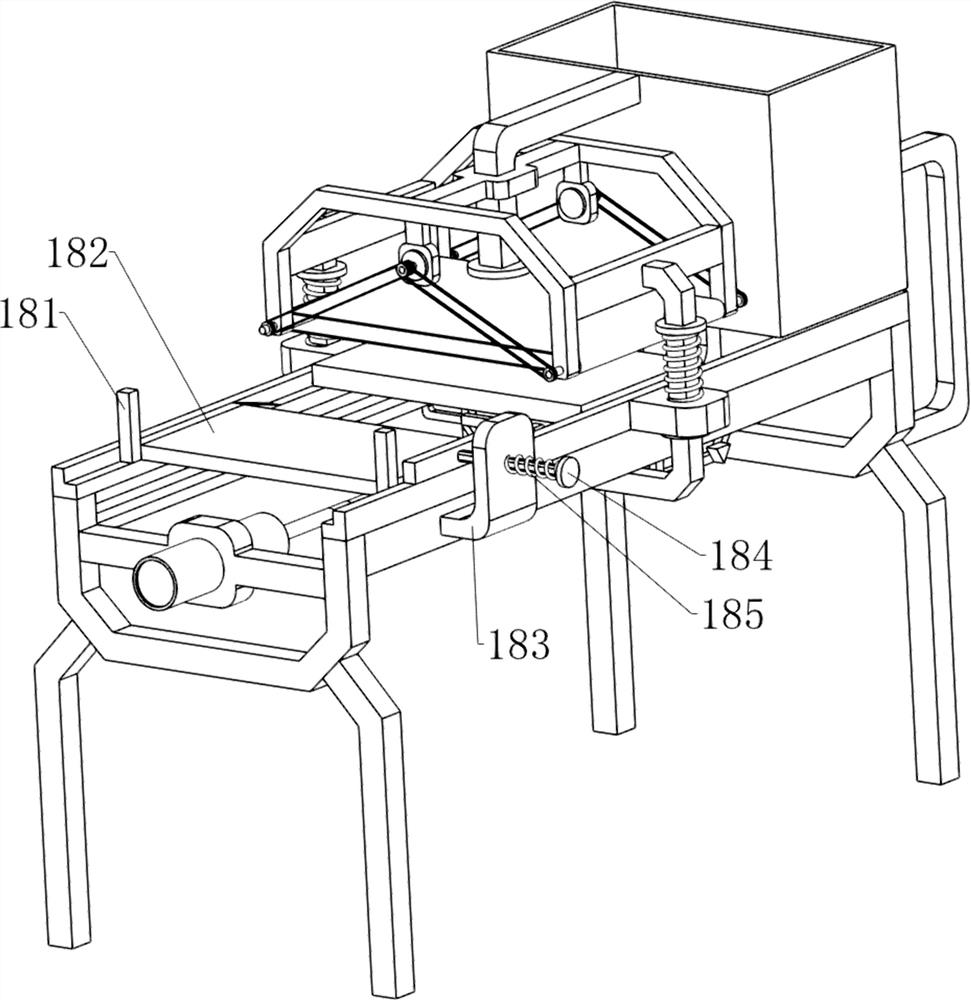

[0060] A kind of automatic physical derusting equipment for iron plate surface used for large parts processing, such as Figure 1-2 As shown, it includes a tripod 1, a carrier frame 2, a first connecting rod 3, a second connecting rod 4, a first fixed block 5, a motor 6, a rotating shaft 7, a belt 8, coarse sandpaper 9, a third connecting rod 10, L-shaped pressing bar 11, first spring 12, guiding mechanism 13 and driving mechanism 14, this equipment has 4 tripods 1, and the supporting frame 2 is arranged between the tops of the tripods 1 on the same lateral side, and the supporting frame 2 is provided with Guide mechanism 13, on the guide mechanism 13 parts, the L-shaped pressure bar 11 is slidably connected, and the first spring 12 is connected between the L-shaped pressure bar 11 and the bearing frame 2, and the third connection is provided on the L-shaped pressure bar 11 tops. Rod 10, the first connecting rod 3 is connected between the front and rear sides of the third conn...

Embodiment 2

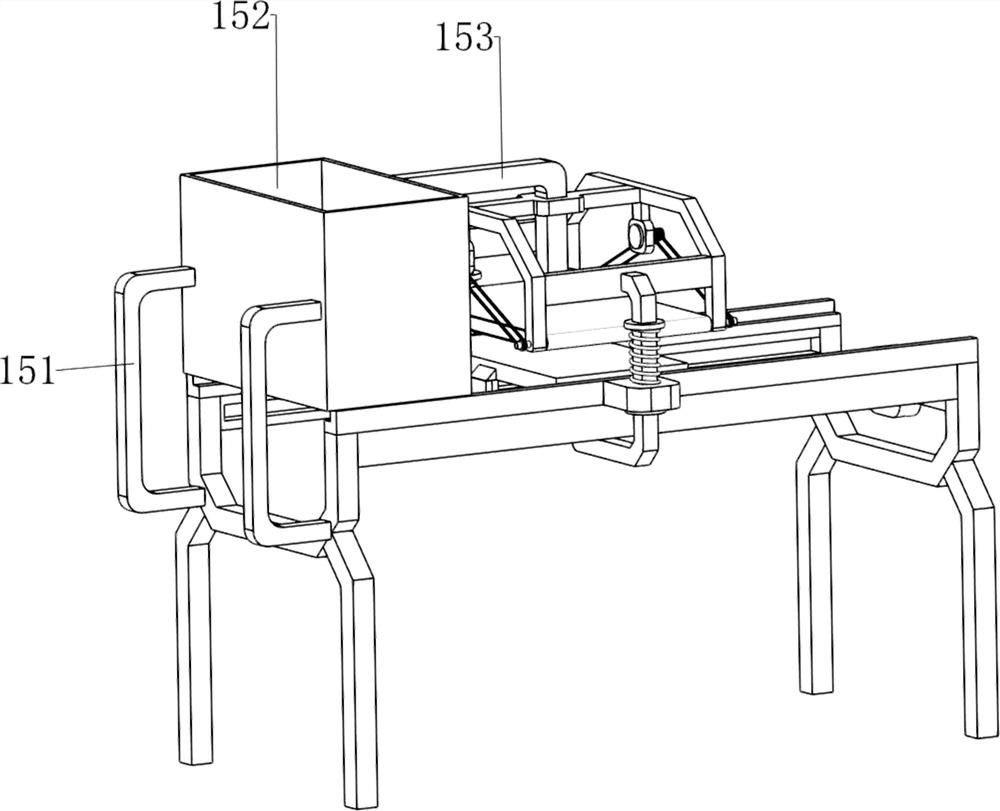

[0065] On the basis of Example 1, such as Figure 3-5 As shown, a blanking mechanism 15 is also included, and the blanking mechanism 15 includes a fourth connecting rod 151, a blanking frame 152 and a third guide rod 153, and the rear side of the carrier frame 2 on the rear side is symmetrically provided with a fourth connecting rod. 151, a blanking frame 152 is provided between the top of the fourth connecting rod 151, the bottom of the blanking frame 152 is in contact with the rear side of the top of the second guide rod 132, and the upper part of the front side of the blanking frame 152 is provided with a third guide rod 153. The guide rod 153 is slidably connected with the middle part of the second connecting rod 4 .

[0066] People put the iron plate in the blanking frame 152. When the first wedge-shaped block 147 moves forward, it drives the iron plate to move forward, so that the coarse sandpaper 9 polishes and removes the rust on the iron plate. After polishing, when t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap