Indentation equipment suitable for corrugated boards with different thicknesses

A corrugated cardboard and indentation technology, which is applied in the manufacture of paper/cardboard containers, papermaking, and rigid/semi-rigid containers, can solve the problems of low automation, low processing efficiency, and high labor intensity, and achieve high automation and processing High efficiency and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

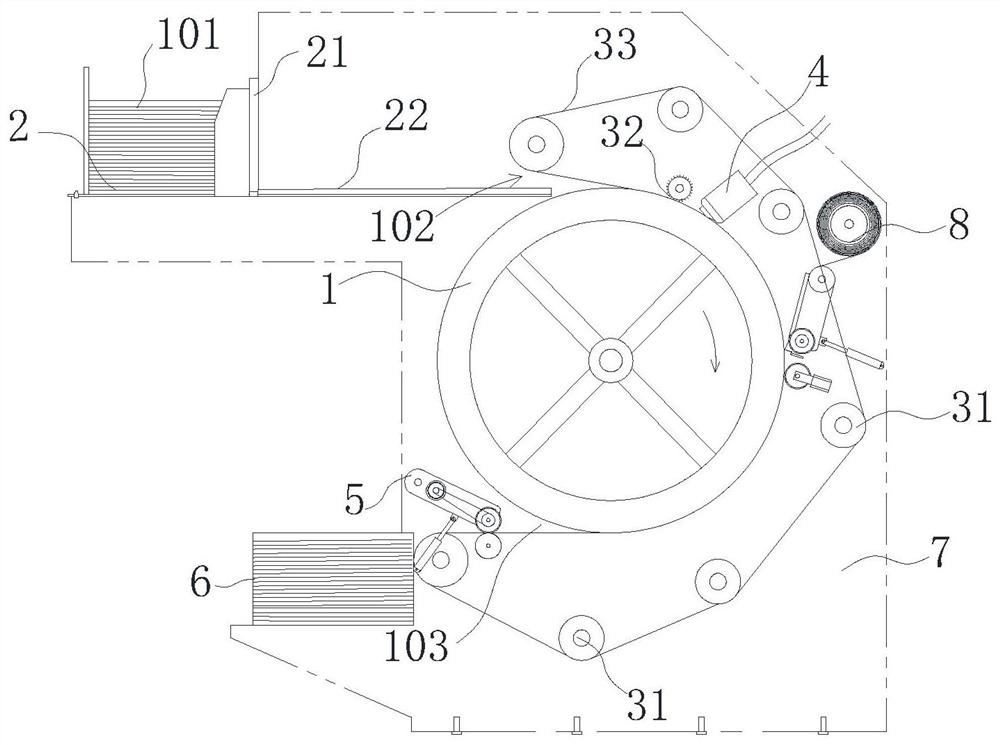

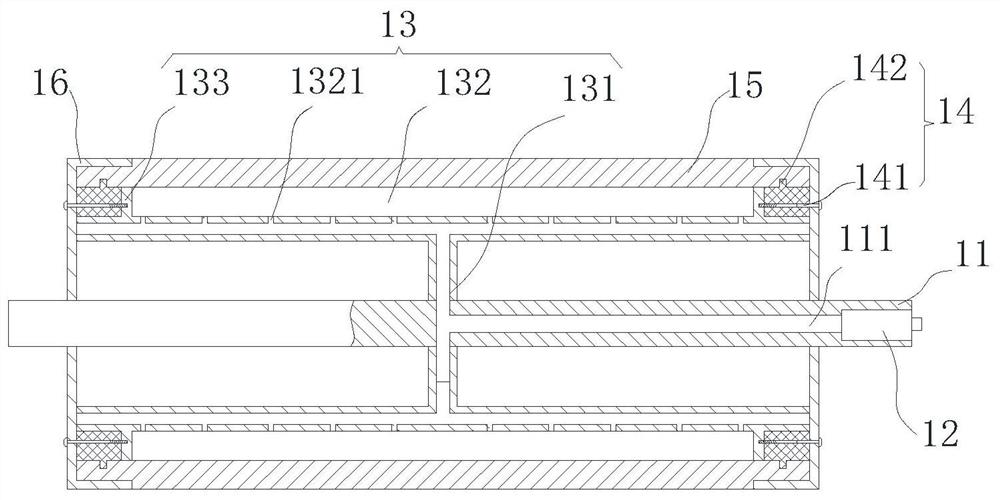

[0035] refer to figure 1 , 7 , the cardboard creasing equipment of this embodiment is used to process one or more creasing on the corrugated cardboard 101 (sheet). The cardboard creasing device in this embodiment includes a frame 7 , a paper feeding device 2 installed on the frame 7 , a conveying device 3 , a glue applying device 4 , a film covering device 8 and a creasing device 5 .

[0036] refer to figure 1 , the paper feeding device 2 is installed on the top of the frame 7, and is used to send out the corrugated cardboard 101 one by one and send it to the conveying device 3 at a constant conveying speed. refer to Figure 4 and 5 , the paper feeding device 2 includes a plurality of beams 29 and a plurality of push blocks 25, the beams 29 are loaded with corrugated cardboard 101 in the form of a pile, and the push block 25 is used to push the corrugated cardboard 101 in the lower layer of the pile Push out one by one.

[0037] In order to facilitate the subsequent desc...

Embodiment 2

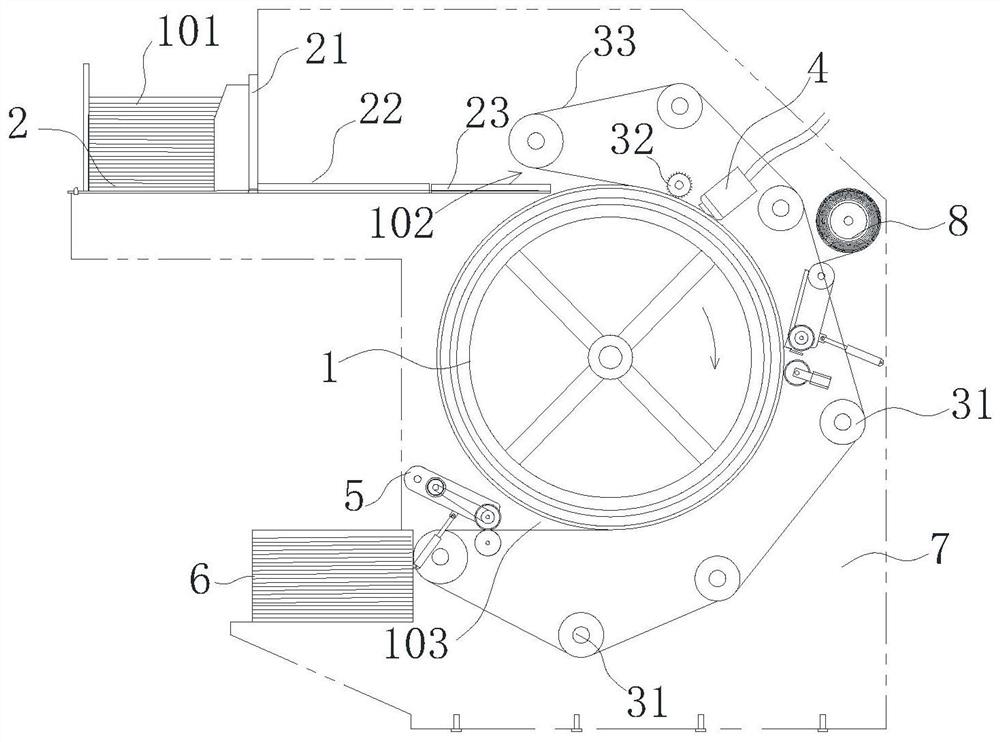

[0065] figure 2 It is a structural schematic diagram of the cardboard creasing equipment of the modified example, figure 2 The cardboard creasing machine shown is suitable for creasing cardboard of different thicknesses. The difference from Example 1 is that the cardboard creasing equipment in this example has adjusted the structure of the conveying device, and the structures of the paper feeding device 2, gluing device 4, film coating device 8 and creasing device 5 are the same as those in the embodiment 1 is exactly the same, to save space, it will not be introduced here.

[0066] The conveying device 3 in this embodiment further includes a second paper supply belt 23 and a position adjustment mechanism for adjusting the height position of the second paper supply belt 23 .

[0067] The second paper supply belt 23 is located between the first paper supply belt 22 and the conveying roller 1 , and its position is adjustable in height, and is used to receive the corrugated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com