Six-direction flexible adjusting method and high-precision flexible carrying equipment

An adjustment method and a technology for handling equipment, which are applied in the directions of mechanical equipment, transportation and packaging, vibration suppression adjustment, etc., can solve the problems of poor adjustment and positioning accuracy, cannot meet the production rhythm of modern production lines, and affect operating efficiency, etc., to achieve hoisting positioning accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

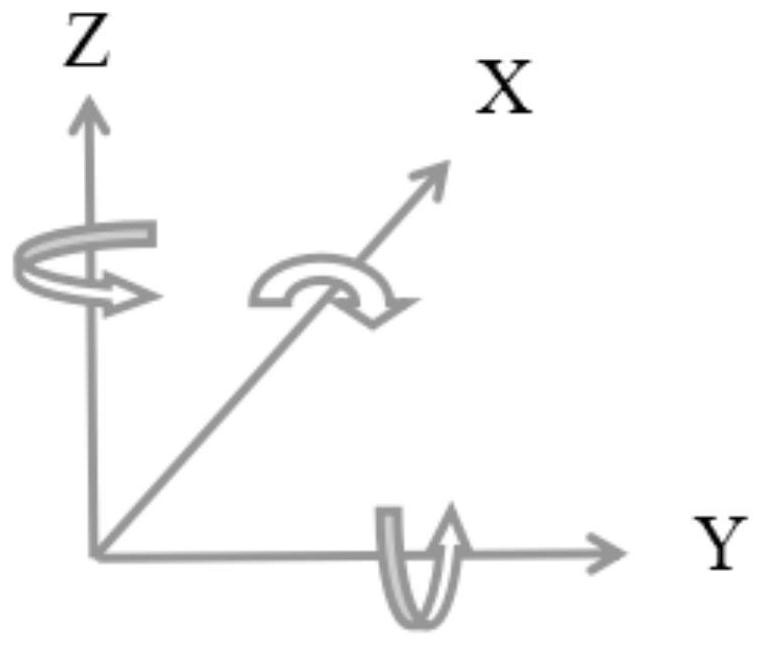

[0029] A six-direction flexible adjustment method, which is mainly used in the joint loading of large-scale materials in construction machinery, of course, it can also be applied in other positioning occasions with corresponding needs, using carts, trolleys, and lifting mechanisms to position hoisted materials, such as figure 1 As shown, the positioning method includes driving the hoisting material to move along the X direction of the cart, moving along the Y direction of the trolley, and lifting along the vertical Z direction. The positioning method also includes making the hoisting material rotate with the X direction as the axis The X-axis yaw movement, the Y-axis yaw movement with the Y-axis as the axis rotation, and the Z-axis yaw movement with the Z-axis as the axis rotation, the hoisting gear and the trolley are flexibly connected; This positioning method can make the orientation adjustment of the lifting materials in the above six directions, figure 1 The direction of ...

Embodiment 2

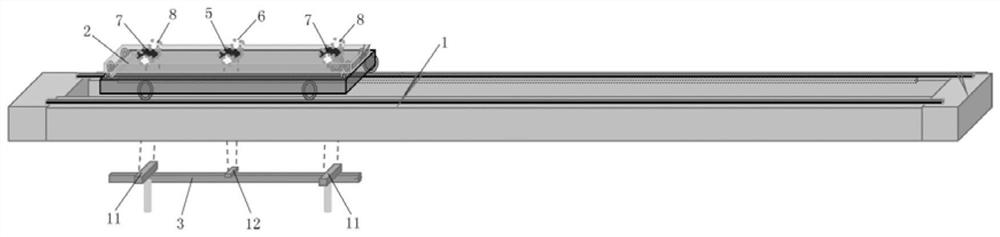

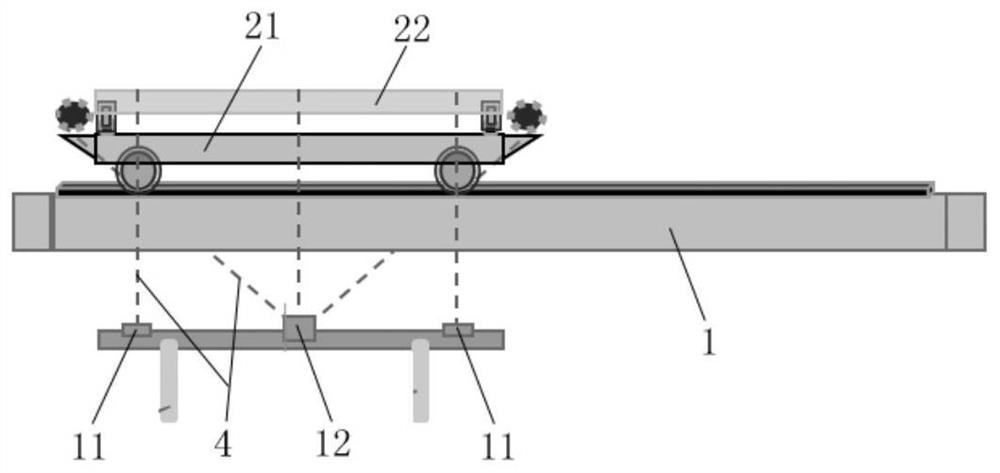

[0036] Provide a high-precision flexible handling equipment for the combined packaging of bulky materials in the construction machinery industry, such as figure 2 and image 3 As shown, it includes cart 1, trolley 2, spreader 3 (shown as a hanging beam in the figure) and the control system for controlling the work of the handling equipment. The two ends of the spreader 3 parallel to the direction of the cart are respectively distributed with two hoisting points. 11. There is a supporting lifting point 12 in the center of the spreader 3, and the two lifting lifting points 11 at each end of the spreader are evenly distributed in a manner parallel to the traveling direction of the cart; The upper corresponding support lifting point 12 is provided with a hoisting winch mechanism 5 for hoisting the spreader 3, such as Figure 4 As shown, the hoisting ropes of the hoisting hoisting mechanism 5 are connected to the supporting lifting points 12, and the trolley 2 is respectively arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com