Automatic lifting platform suitable for wheeled robot and working method of automatic lifting platform

A wheeled robot, automatic lifting technology, applied in the direction of lifting frame, lifting device, etc., can solve the problem of height difference between inside and outside, and achieve the effect of improving accuracy, good application prospect and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

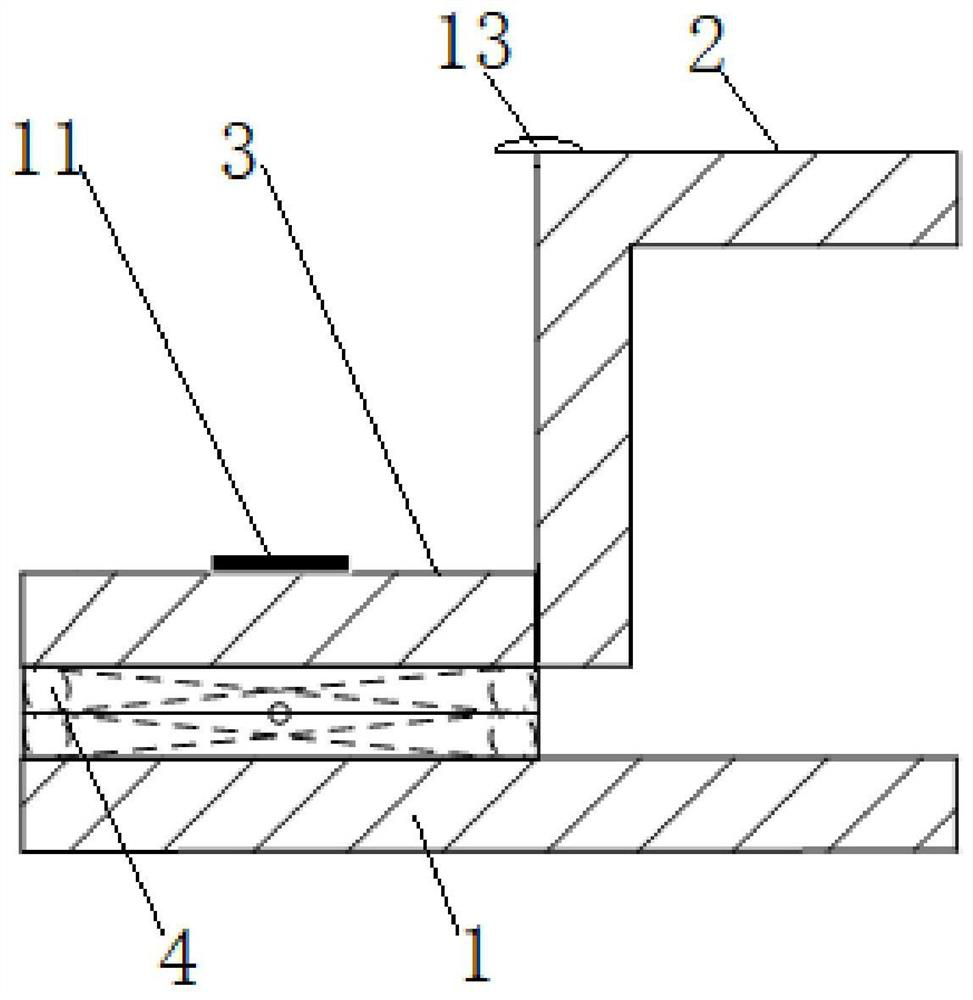

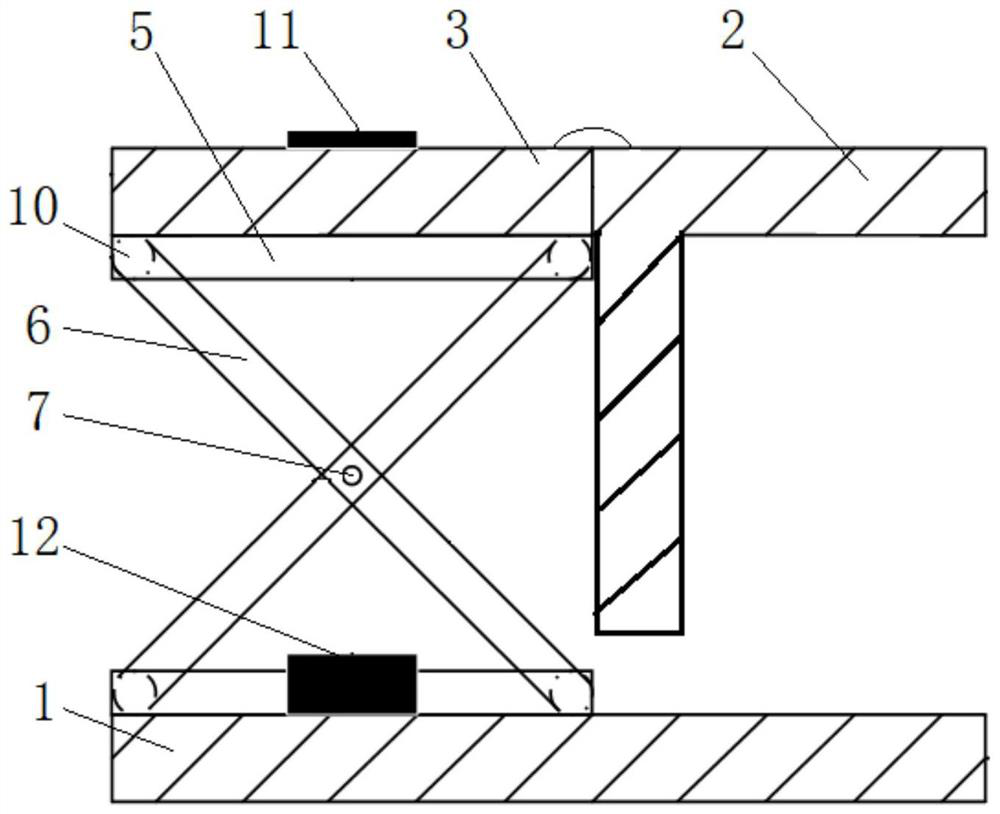

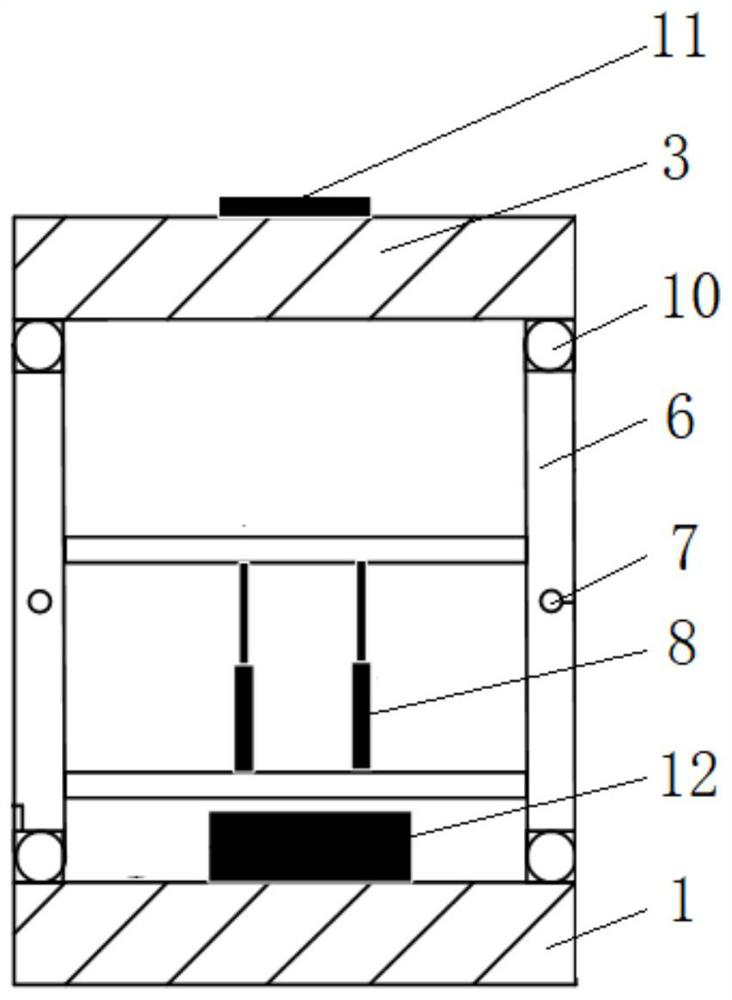

[0032] The automatic lifting platform suitable for wheeled robots of the present invention includes a lifting floor 3 and a lifting mechanism 4, the lifting mechanism 4 is fixed on the ground 1, and several weight sensors 11 are arranged on the lifting floor 3, and the weight sensors 11 are connected with the lifting mechanism 4 ; The lifting floor 3 is on the same level as the outdoor floor when it is lowered, such as figure 1 ; Lifting floor 3 is on the same level with indoor floor 2 when it rises, as figure 2 and image 3 .

[0033] Regarding the setting of weight sensor 11, following two schemes can be taken:

[0034] Solution 1: The weight sensor 11 is set with an activation threshold matching the weight of the wheeled robot. For example, the activation threshold of the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com