Short-cantilever ballasting single-hole variable-height beam and construction method

A technology of variable height and cantilever, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems that the structural force cannot meet the requirements, and achieve the effect of maintaining beautiful features, reasonable force, and safe and reliable structural force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

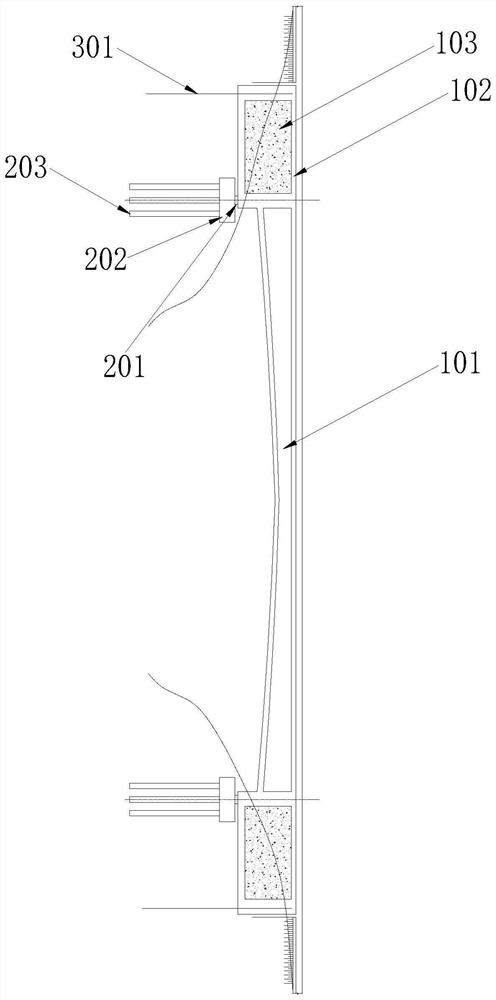

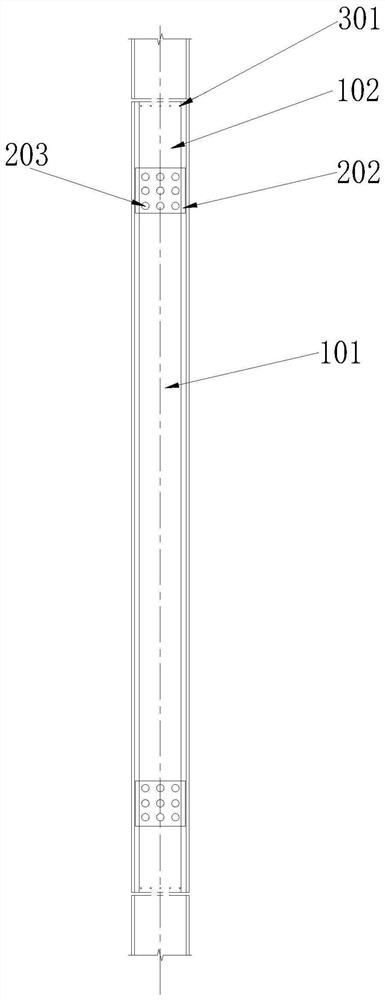

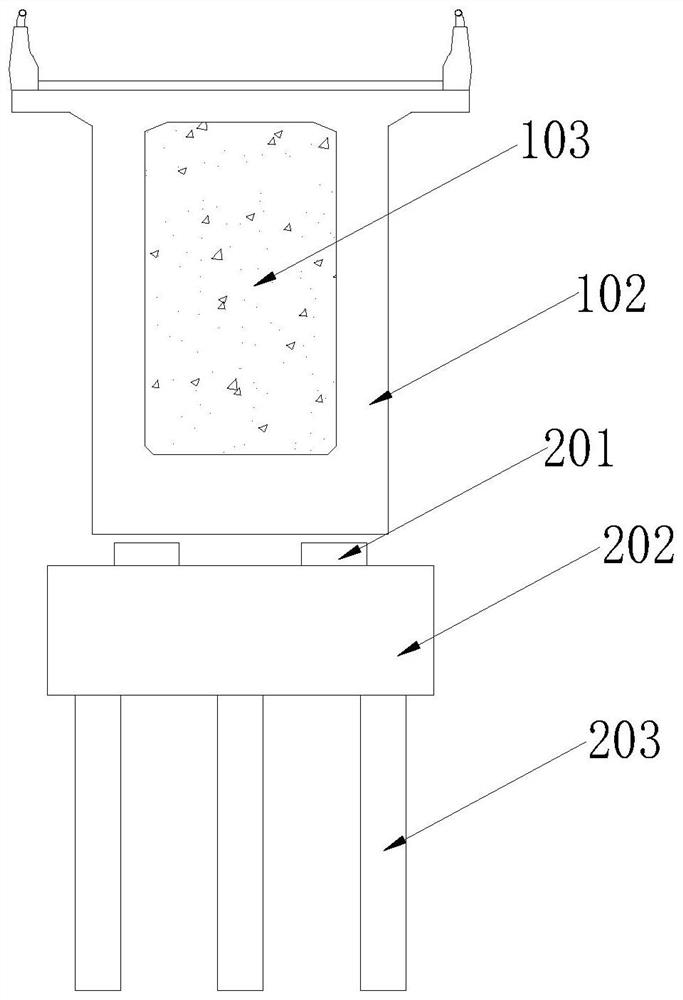

[0040] Such as Figure 1-4 As shown, a short-cantilever ballast-weight single-hole variable-height beam provided in this embodiment includes: a mid-span variable-height section 101 of the main girder, a short-cantilever ballast section 102 of the main girder, a ballast material 103, a pier support 201, Pier cap 202, pier foundation 203 and prestressed anchor rod 301. It can be seen from the figure that a pier foundation 203 and a pier cap 202 are constructed at the bridge position. Wherein, the pier foundation 203 adopts a pile foundation or an enlarged foundation.

[0041] The invention solves the inadaptability problem of span matching of the continuous variable height beam system; the continuous variable height beam system must lay side spans due to the limitation of the side-to-middle span ratio. This kind of bridge type cannot be adopted under the condition of limited terrain; the present invention adopts the idea of short cantilever ballast to realize single-span var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com