Power take-off system and gearbox integrated with oil pump

A gearbox and oil pump technology, which is applied in the direction of pressure lubrication of lubricating pumps, pressure lubricants, and engine lubrication, etc. It can solve the problems of reducing the volume of the casing, the length of the power take-off shaft, and the overall weight reduction, so as to ensure the lubrication efficiency , Ease of assembly and shortened length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

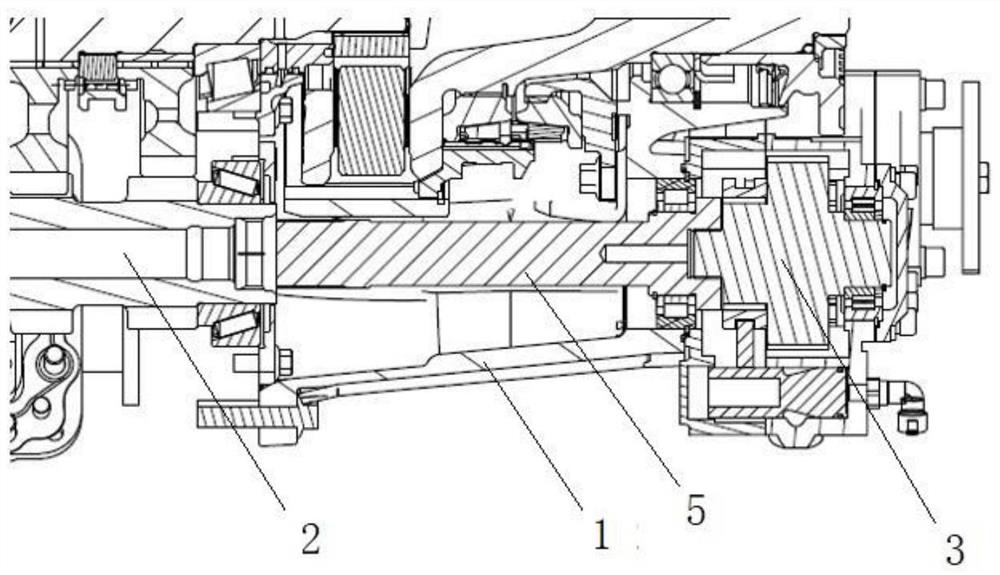

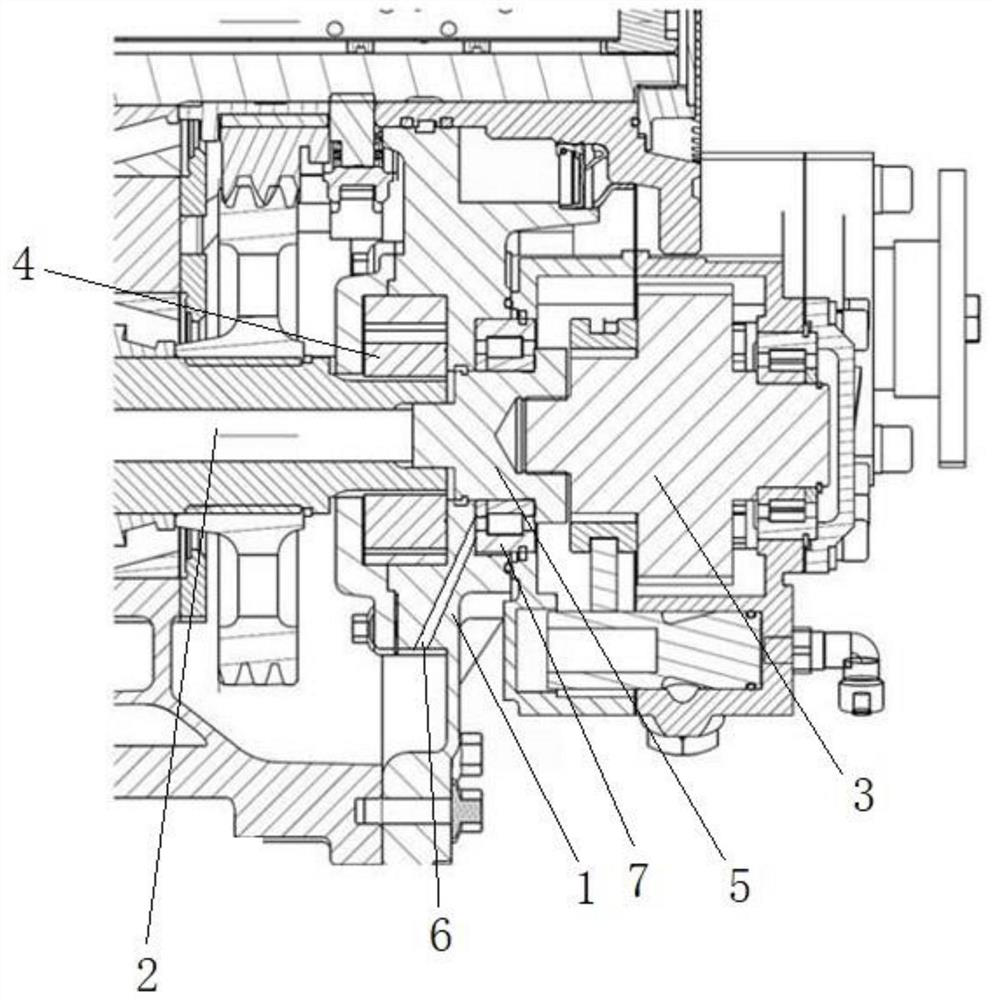

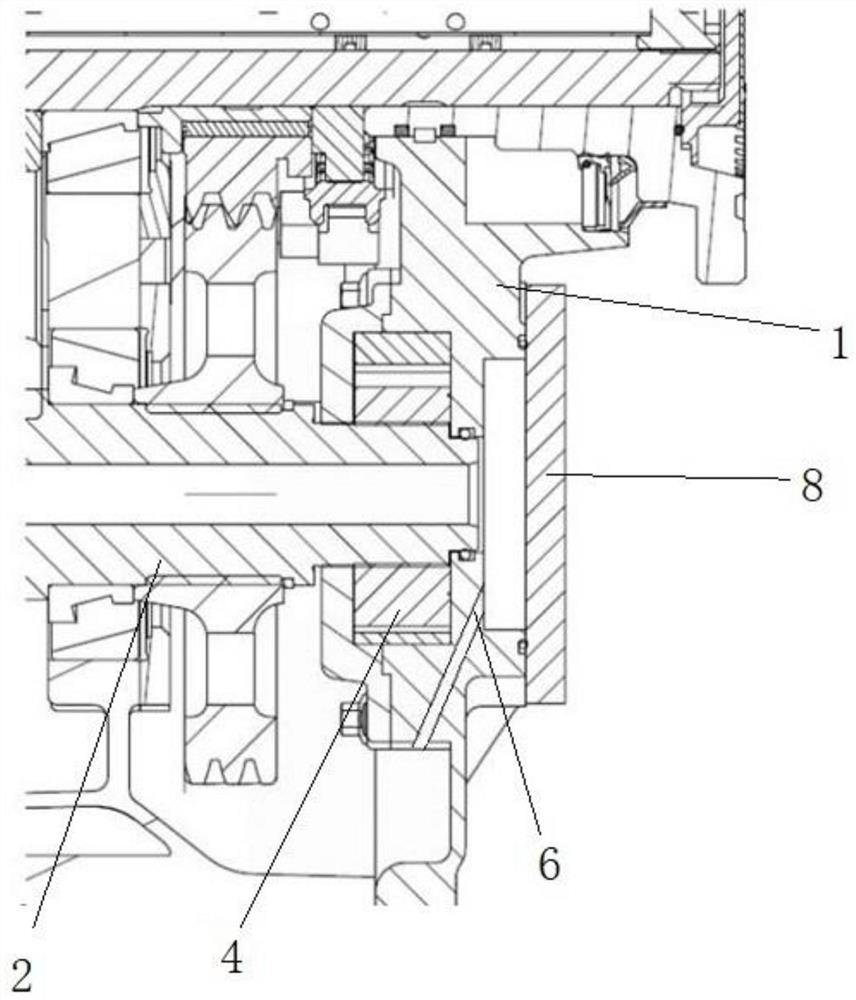

[0084]The invention discloses a power take-off system with an integrated oil pump. When a cooler and a filter are not installed on the rear casing, it includes a gearbox rear casing 100, and the rear casing 100 of the gearbox is integrated with a An oil inlet 25, an oil outlet 26 and a lubricating oil circuit for connecting the oil inlet 25 and the oil outlet 26, the lubricating oil circuit includes an oil inlet pipeline 108, an intermediate pipeline 109 and an oil outlet pipeline 116. The oil inlet pipeline 108 and the oil outlet pipeline 116 are blind holes arranged on the side wall of the rear casing, and the intermediate pipeline 109 is a blind hole arranged on the side wall of the rear casing. The hole structure, the multi-function transfer hole 120 and the oil passage hole 111 provided on the intermediate pipeline 109 may not be processed, and the intermediate pipeline 109 includes a coaxially arranged first pipe communicating with the oil outlet pipeline 116 A pipeline ...

Embodiment 2

[0086] The invention discloses a power take-off system with an integrated oil pump. When only the filter 50 is installed on the rear casing, it includes a gearbox rear casing 100, and an oil inlet is integrated on the rear casing 100 of the gearbox. port 25, oil outlet 26 and a lubricating oil circuit for connecting the oil inlet 25 and the oil outlet 26, the lubricating oil circuit includes an oil inlet pipe 108, an intermediate pipe 109 and an oil outlet pipe 116, The oil inlet pipeline 108 and the oil outlet pipeline 116 are blind hole structures arranged on the side wall of the rear housing, and the intermediate pipeline 109 is a blind hole structure arranged on the side wall of the rear housing , the intermediate pipeline 109 is provided with a multi-function adapter hole 120 for connecting the filter installed on the rear housing with the oil outlet pipeline 116, and a multifunctional adapter hole 120 for connecting the filter installed on the rear housing with the oil ou...

Embodiment 3

[0088]The present invention discloses a power take-off system with an integrated oil pump. When only a small cooler 60 is installed on the rear casing, it includes a gearbox rear casing 100, and an oil inlet is integrated on the rear casing 100 of the gearbox. port 25, oil outlet 26 and a lubricating oil circuit for connecting the oil inlet 25 and the oil outlet 26, the lubricating oil circuit includes an oil inlet pipe 108, an intermediate pipe 109 and an oil outlet pipe 116, The oil inlet pipeline 108 and the oil outlet pipeline 116 are blind hole structures arranged on the side wall of the rear housing, and the intermediate pipeline 109 is a blind hole structure arranged on the side wall of the rear housing , the intermediate pipeline 109 is provided with a multifunctional adapter hole 120 for connecting the small cooler installed on the rear casing and the oil outlet pipeline 116, and a small cooler installed on the rear casing and the oil outlet pipe 116. The oil passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com