Variable-thrust flexible nozzle system of miniature solid rocket engine

A technology of solid rockets and flexible nozzles, which is applied in the direction of rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as serious devices, poor combustion controllability, ablation, etc., and achieve improved control accuracy, simple structure, The effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

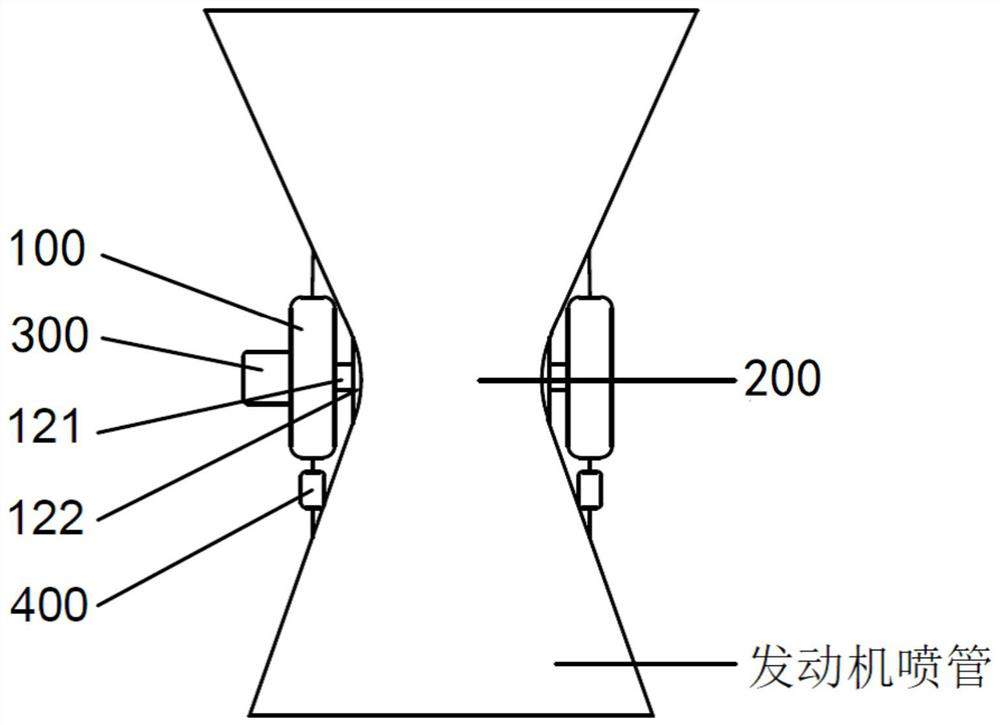

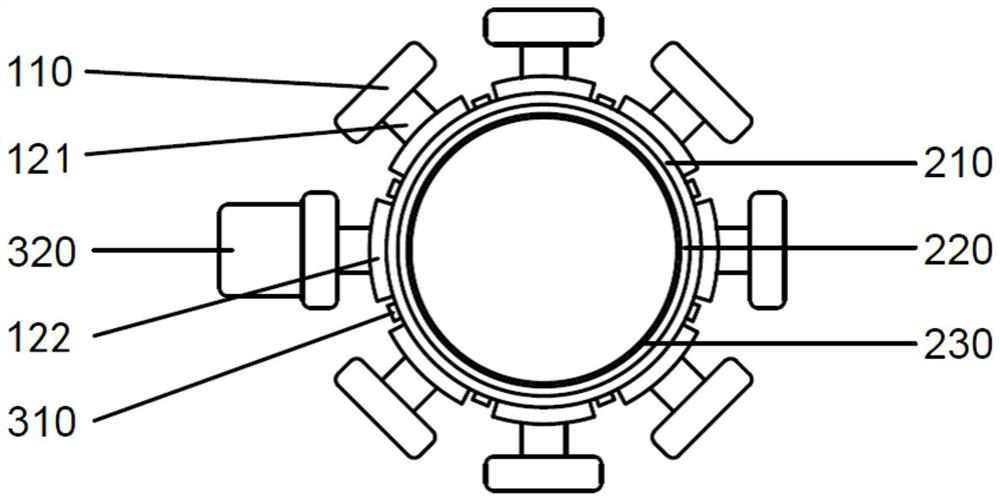

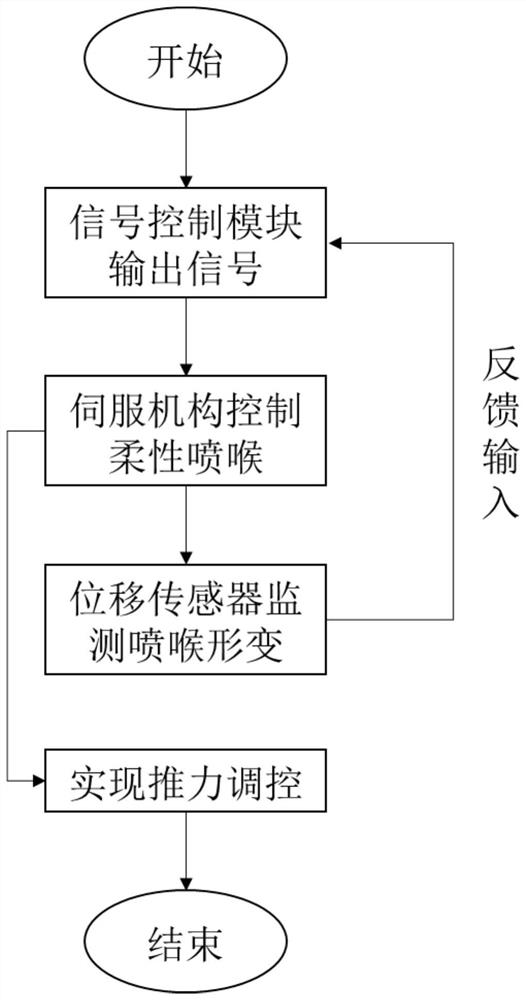

[0031] It is the variable thrust miniature solid rocket motor flexible nozzle system of the present invention, which includes a displacement acquisition module 300, a control module 400, a flexible nozzle throat 200 and several servo mechanisms 100 arranged in the circumferential direction of the flexible nozzle throat 200;

[0032] The two ends of the flexible spray throat 200 are respectively fixedly connected with the nozzle contraction section and the nozzle expansion section. The servo mechanism 100 includes a servo motor 110, a transmission rod 121 and a transmission plate 122. The servo motor 110 is connected with the transmission rod 121, and the transmission rod 121 is connected with the transmission rod 121. The transmission plate 122 is connected, and the transmission plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com