Novel three-cylinder single-action diaphragm pump fluid end

A diaphragm pump, single-acting technology, applied to pumps with flexible working elements, parts of pumping devices for elastic fluids, pumps, etc., can solve the problem that the structural strength cannot meet the requirements of supercritical high-pressure slurry operation Ensure the service life of the liquid end of the diaphragm pump, casting defects and stress concentration safety accidents, etc., to achieve the effect of reducing tonnage and appearance volume, improving safety and stability, and avoiding operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

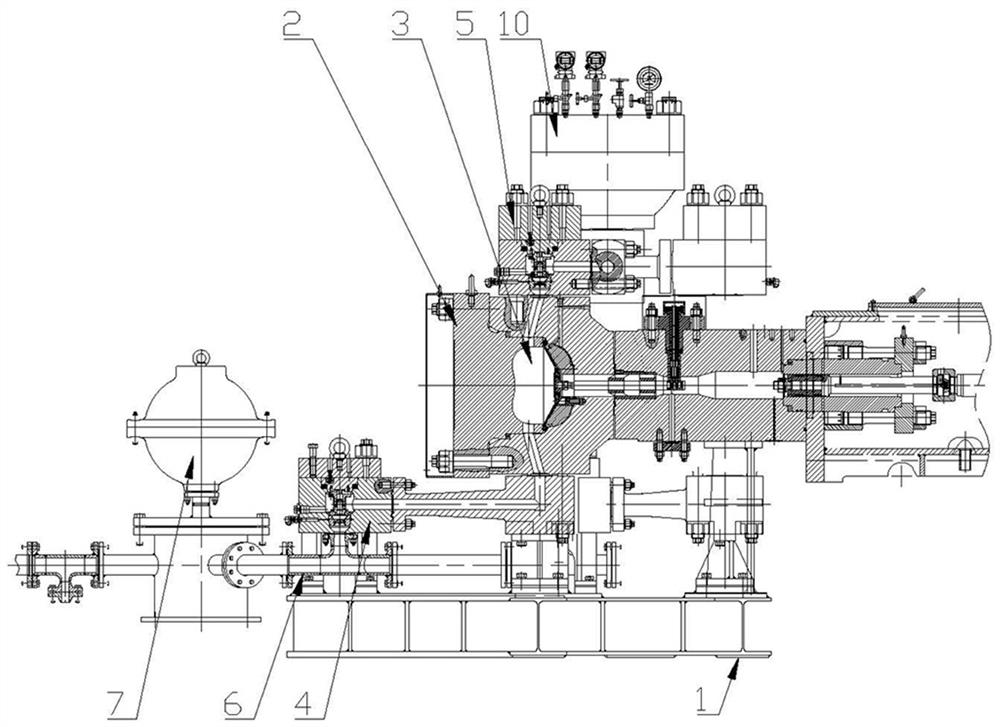

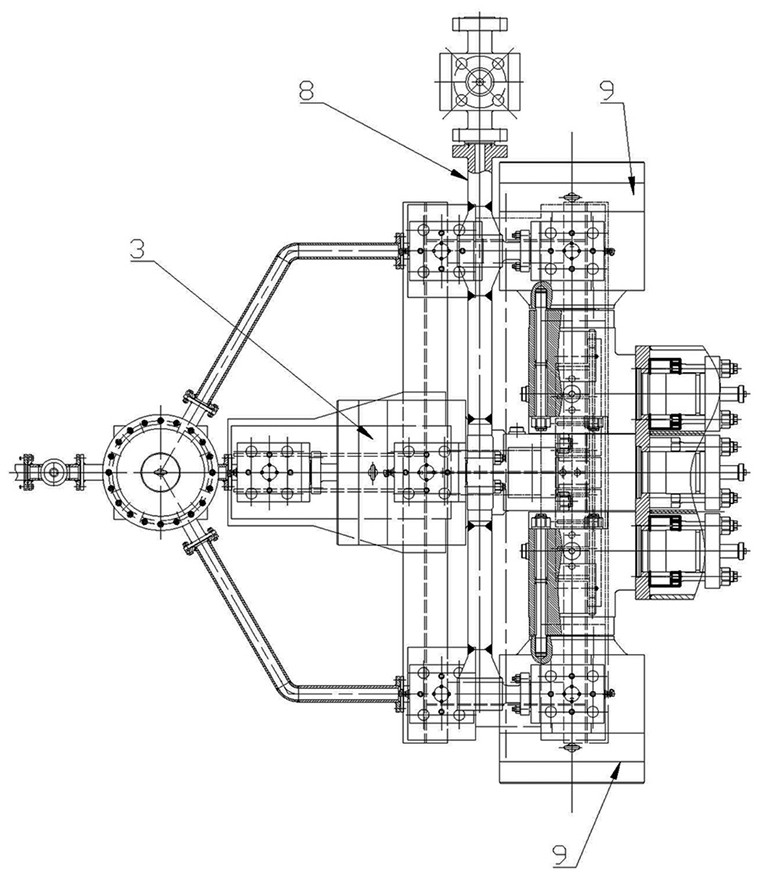

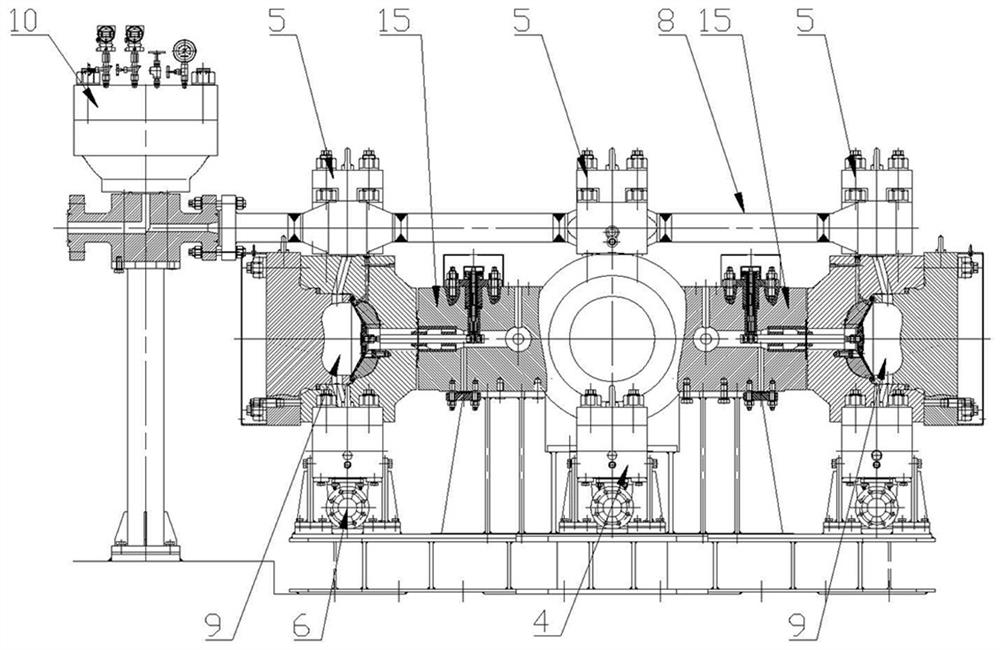

[0031] The invention comprises a base 1, on which a diaphragm pump body 2 is arranged, and is characterized in that: a diaphragm chamber is arranged in the middle and both sides of the diaphragm pump body 2, and the three diaphragm chambers form an isosceles triangle, and the middle diaphragm chamber is equal to The apex of the waist triangle; the diaphragm axes of the diaphragm chambers 9 on both sides are the same straight line, and the diaphragm axis of the middle diaphragm chamber 3 is perpendicular to the diaphragm axes of the diaphragm chambers 9 on both sides.

[0032] As a preferred solution of the present invention, the base 1 is provided with a feed valve box 4 connected to the inlet of the diaphragm chamber; the top of the diaphragm pump body 2 is provided with a discharge valve box 5 communicated with the outlet of the diaphragm chamber; the feed valve The box 4 is connected with the feed compensation system 7 through the feed pipe 6 , and the discharge valve box 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com