Drying equipment used before flour packaging

A drying equipment and packaging technology, which is applied to the field of drying equipment before flour packaging, can solve the problems of waste, trouble in collection, and inability to control drying temperature, and achieve the effect of preventing waste and improving drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

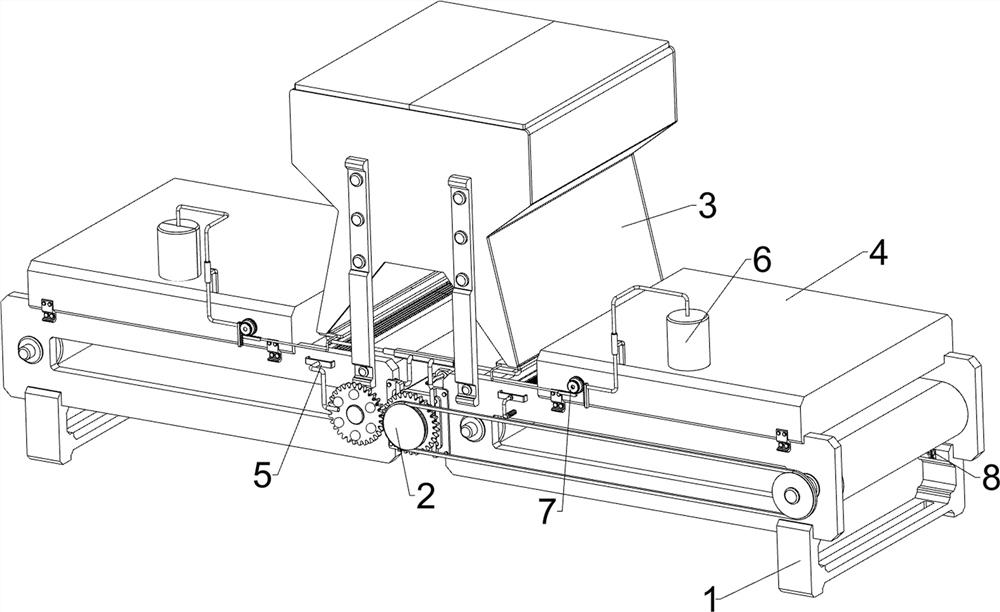

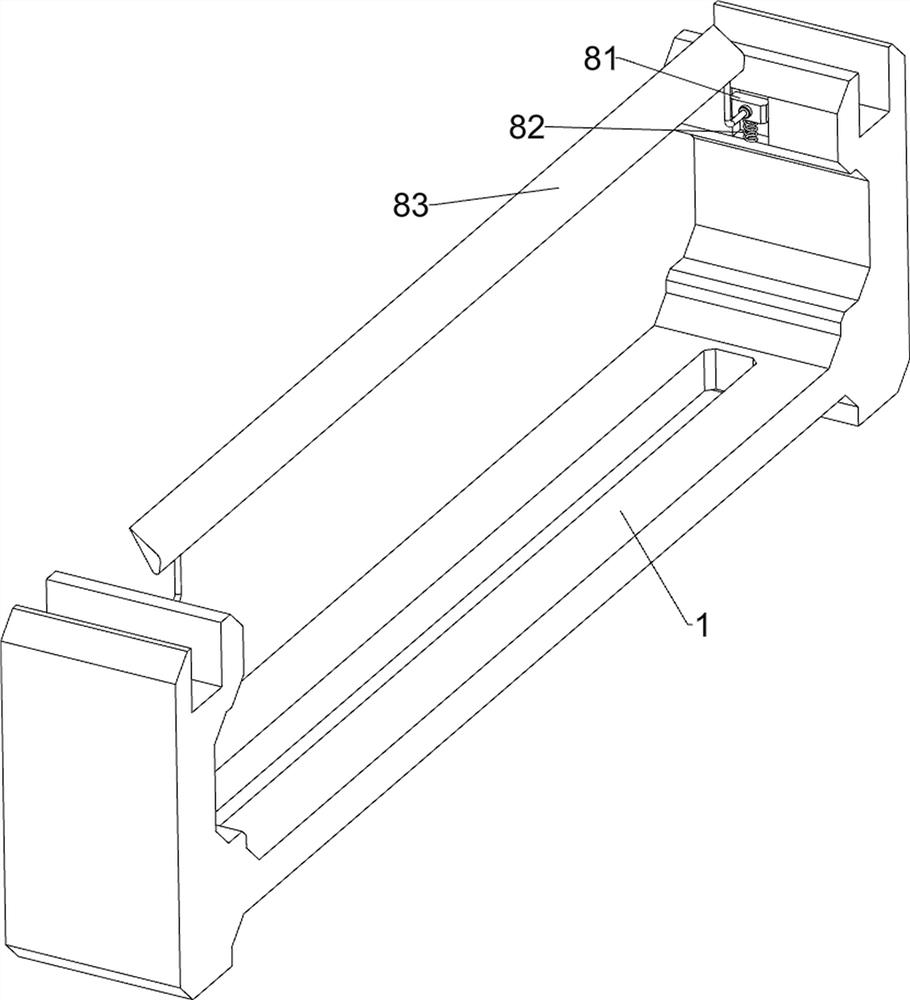

[0026] A kind of drying equipment before flour packaging, such as Figure 1-3 As shown, it includes a support 1, an output assembly 2, a blanking assembly 3 and a drying lamp 4. The output assembly 2 is provided on the support 1, the blanking assembly 3 is provided on the output assembly 2, and the left and right sides of the support 1 are provided with There are drying lights4.

[0027] When the flour needs to be dried, start the drying lamp 4, then place the flour in the feeding assembly 3, then control the feeding assembly 3 to discharge, the flour will fall onto the output assembly 2, and then start the output assembly 2. The output unit 2 will drive the flour through the lower side of the drying lamp 4, and the drying lamp 4 will dry the flour. When the flour is completely dried, turn off the drying lamp 4 and the output unit 2.

[0028] The output assembly 2 includes a geared motor 21, a conveyor belt 22, a first gear 23, a second gear 24 and a transmission pulley set 2...

Embodiment 2

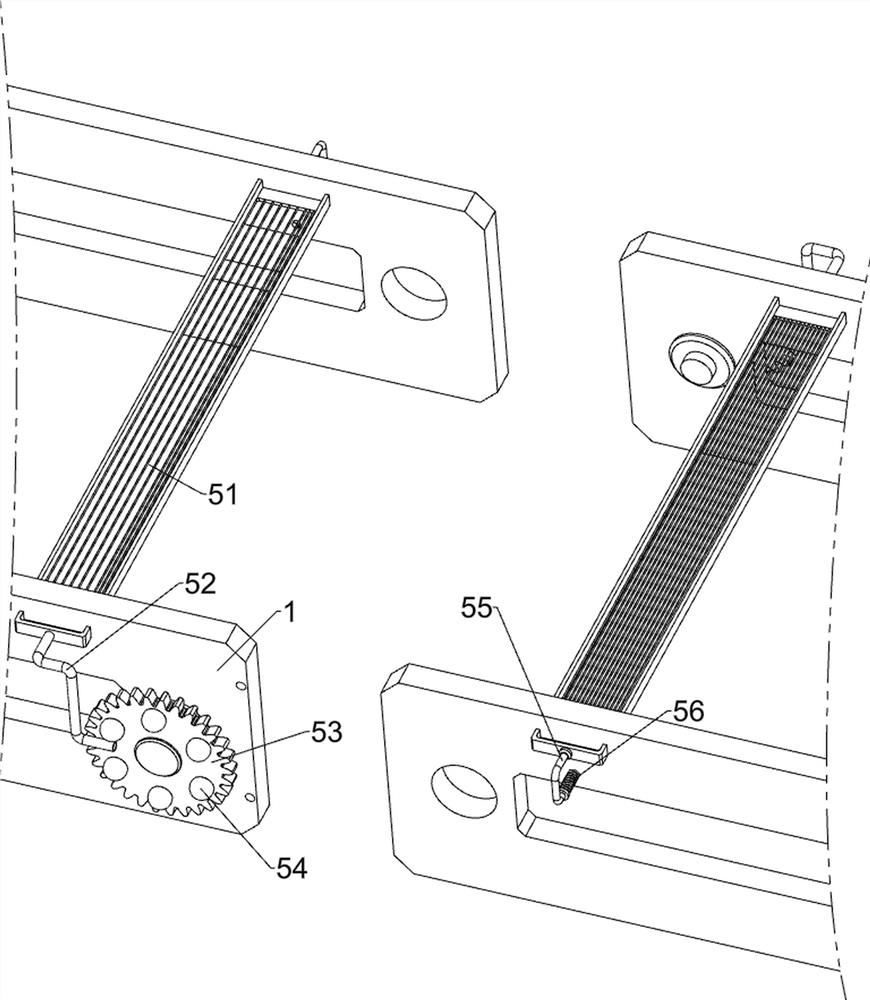

[0033] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 and Image 6 Shown, also comprise dispersing assembly 5, dispersing assembly 5 comprises screen frame 51, special-shaped rod 52, the 3rd gear 53, protrusion 54, concave rod 55 and first elastic member 56, the left and right sides of support 1 all Sliding type is provided with screen frame 51, is all connected with special-shaped bar 52 on the screen frame 51, is connected with the 3rd gear 53 on the left side of the rear portion of right conveyor belt 22, the setting that is all evenly spaced on the 3rd gear 53 and the first gear 23. There are a plurality of protrusions 54, and the protrusions 54 are correspondingly matched with the special-shaped rods 52. The screen frame 51 is connected with a concave rod 55, and the concave rod 55 is connected with the support 1 in a sliding manner. Between the concave rod 55 and the support 1 Both are connected with a first elastic member 56 .

[0034] When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com