Differential pressure transmitter verification system

A differential pressure transmitter, low pressure technology, applied in the field of differential pressure transmitter calibration system, can solve the problem of reducing the accuracy and resolution of calibration differential pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

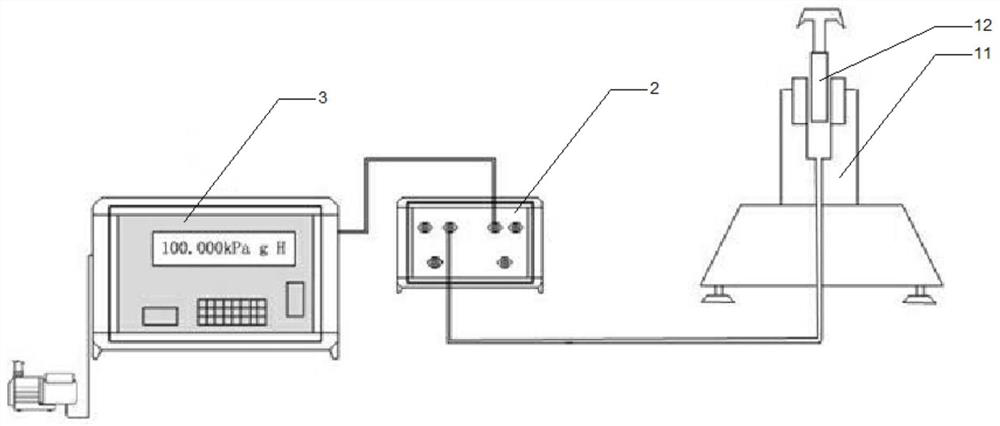

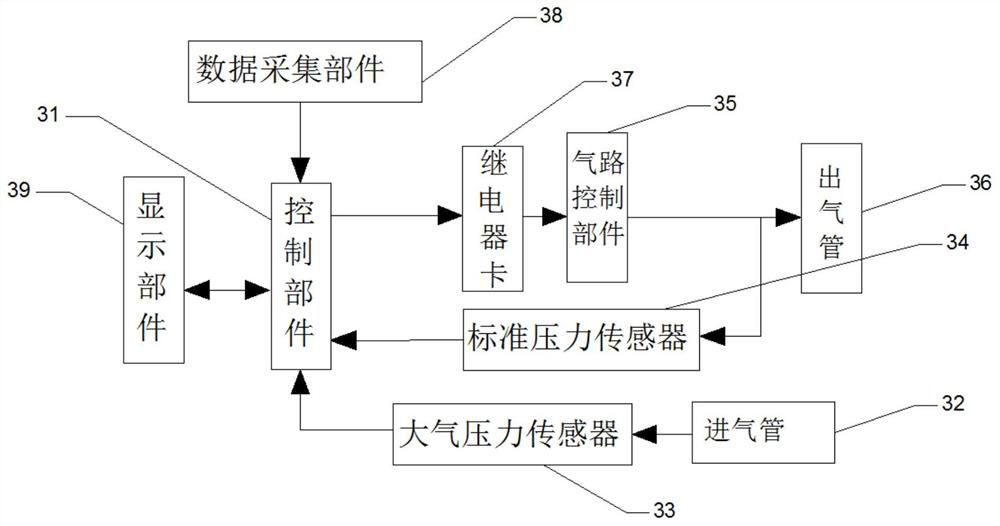

[0029] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a differential pressure transmitter verification system, the system includes:

[0030] A pressure gauge component, the pressure gauge component includes a piston cylinder 11 and a piston body 12, and the piston body 12 is arranged on the piston cylinder 11;

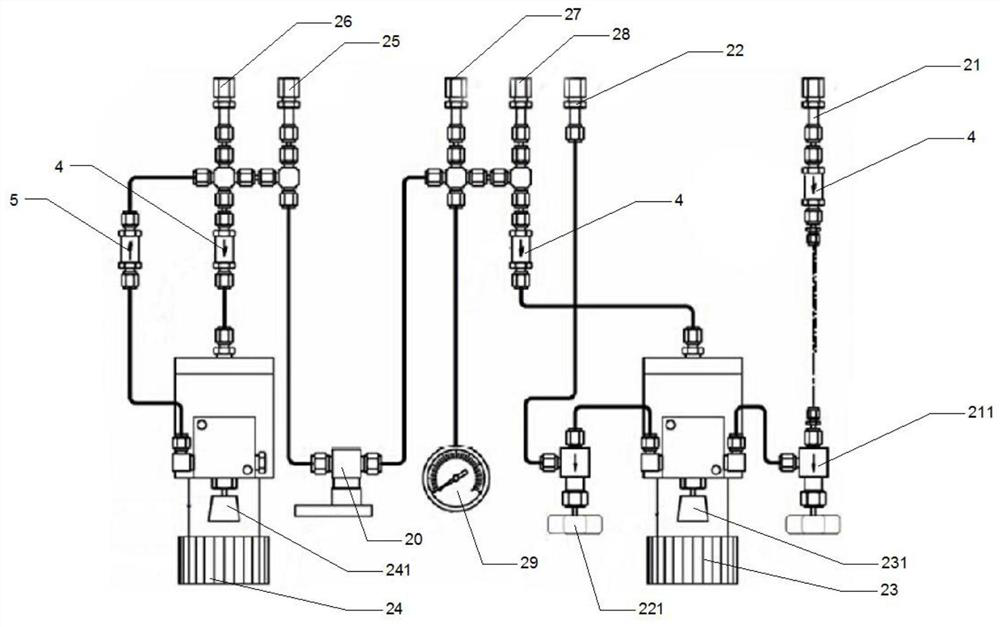

[0031]Verification parts, the verification parts include air supply connecting pipe 21, exhaust connecting pipe 22, first regulator 23, second regulator 24, low pressure test pipe 25, low pressure reference pipe 26, high pressure test pipe 27, high pressure reference pipe 28 and Referring to the pressure gauge 29, one end of the gas supply connection pipe 21 is connected to the first regulator 23, one end of the high pressure test tube 27 is connected to the first regulator 23, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com