A kind of preparation method of fe(se,te) superconducting wire

A technology of superconducting wire rod and mixed powder, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. Simple and effective low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

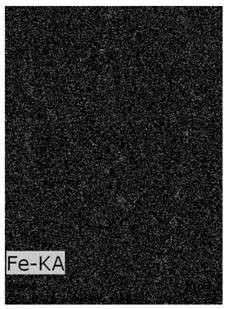

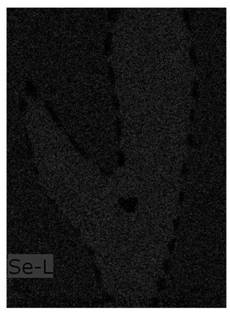

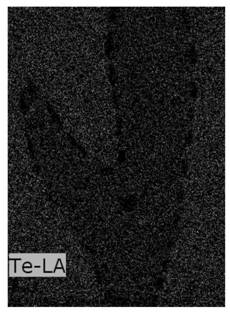

Image

Examples

Embodiment 1

[0040] This embodiment includes the following steps:

[0041] Step 1. In a glove box filled with argon, place the mixed powder in an agate mortar and grind for 30 minutes; the mixed powder is composed of iron powder, selenium powder, tellurium powder, silver powder and selenium dioxide powder according to 1.0:0.5 : 0.5:0.05:0.05 molar ratio composition;

[0042] The iron powder is reduced iron powder, and the mass purity is 99.99%, the mass purity of the selenium powder, the tellurium powder and the silver powder are all 99.99%, and the mass purity of the selenium dioxide powder is 99.9%;

[0043] Step 2. In a glove box filled with argon gas, put the mixed powder after grinding in step 1 into a tableting die and seal it, then take it out and place it on a tableting machine for compression treatment to obtain doped Fe- Se-Te green body; the pressure of the pressing treatment is 10MPa, and the time is 10min;

[0044] Step 3: The doped Fe-Se-Te body obtained in step 2 is taken ...

Embodiment 2

[0057] This embodiment includes the following steps:

[0058] Step 1. In a glove box filled with argon, place the mixed powder in an agate mortar and grind for 30 minutes; the mixed powder is composed of iron powder, selenium powder, tellurium powder, silver powder and selenium dioxide powder according to 1.0:0.5 : 0.5:0.01:0.01 molar ratio composition;

[0059] The iron powder is reduced iron powder, and the mass purity is 99.99%, the mass purity of the selenium powder, the tellurium powder and the silver powder are all 99.99%, and the mass purity of the selenium dioxide powder is 99.9%;

[0060]Step 2. In a glove box filled with argon gas, put the mixed powder after grinding in step 1 into a tableting die and seal it, then take it out and place it on a tableting machine for compression treatment to obtain doped Fe- Se-Te green body; the pressure of the pressing treatment is 10MPa, and the time is 10min;

[0061] Step 3: The doped Fe-Se-Te body obtained in step 2 is taken o...

Embodiment 3

[0071] This embodiment includes the following steps:

[0072] Step 1. In a glove box filled with argon, the mixed powder is placed in an agate mortar and ground for 60 minutes; the mixed powder is composed of iron powder, selenium powder, tellurium powder, silver powder and selenium dioxide powder according to 0.9:0.2 : 0.2:0.01:0.01 molar ratio composition;

[0073] The iron powder is reduced iron powder, and the mass purity is 99.999%, the mass purity of the selenium powder, the tellurium powder and the silver powder are all 99.999%, and the mass purity of the selenium dioxide powder is 99.99%;

[0074] Step 2. In a glove box filled with argon gas, put the mixed powder after grinding in step 1 into a tableting die and seal it, then take it out and place it on a tableting machine for compression treatment to obtain doped Fe- Se-Te green body; the pressure of the pressing treatment is 5MPa, and the time is 2min;

[0075] Step 3: The doped Fe-Se-Te body obtained in step 2 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| superconducting critical temperature | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com