Superconducting radial thick coil for superconducting cyclotron, and winding and dipping method of superconducting radial thick coil

A cyclotron and superconducting coil technology, which is applied in the direction of superconducting magnets/coils, coil manufacturing, magnetic resonance accelerators, etc., can solve problems such as easy quenching and difficulty in ensuring that the coils are strictly coaxial and strictly parallel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

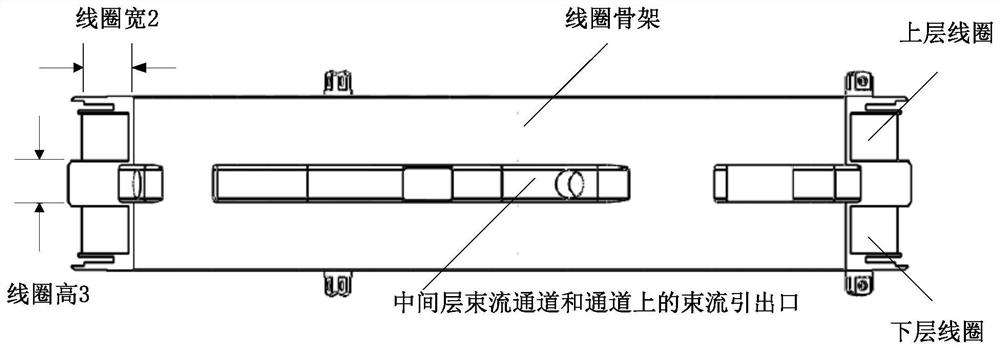

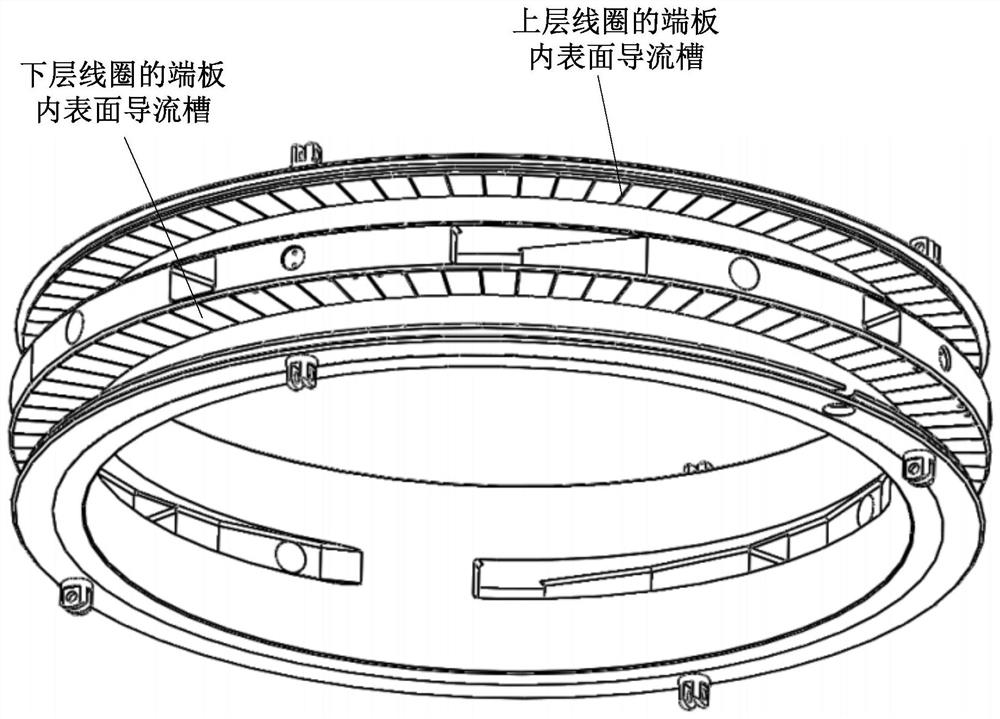

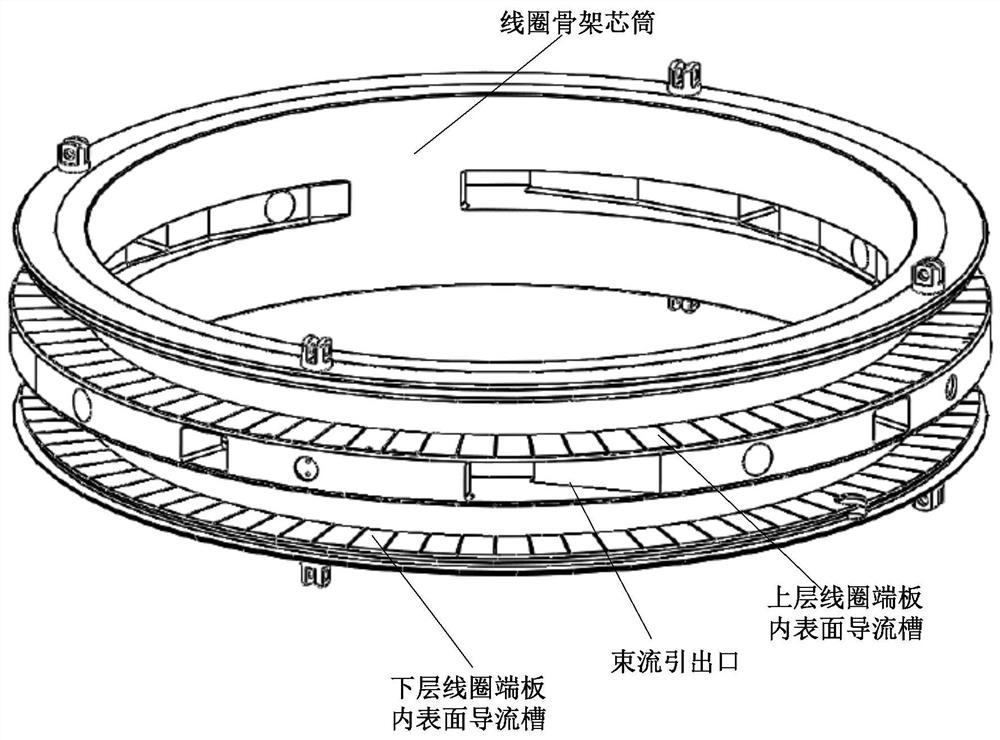

[0042] Design principle of the present invention

[0043] 1. Three characteristics of the cyclotron superconducting coil: First, the center of the superconducting coil frame is a strong magnetic field of the iron core, which is a feature that the superconducting solenoid mentioned in the comparison document does not have. The strong magnetic field comes from the core magnetic poles installed in the center hole of the coil bobbin, and the superconducting coil is installed between the core magnetic poles and the iron core yoke; due to the existence of the iron core and the gathering effect of the core magnetic pole edges on the magnetic field, the superconducting cyclotron is close to the coil The magnetic field at the cross-section position of the superconducting coil near the inner wall of the skeleton is much higher than the magnetic field at the cross-section position of the coil in the case of no iron core in the reference document; second, because the magnetic field strengt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com